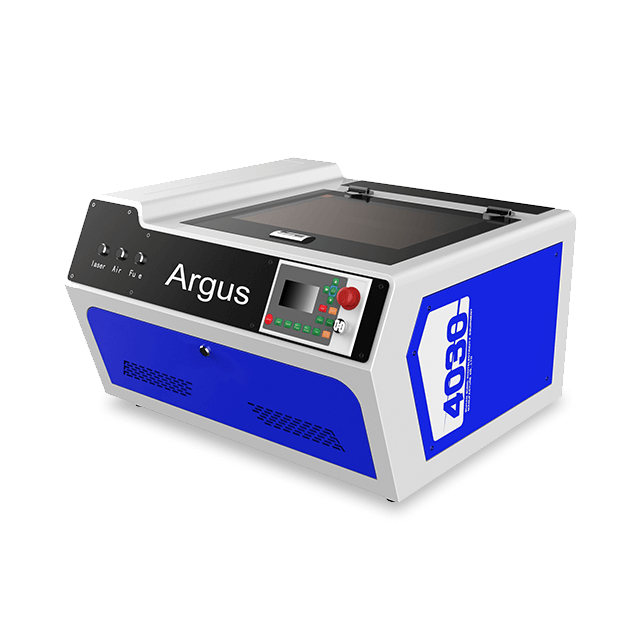

Furniture Industry

Laser cutting is used to create intricate designs, patterns, and precise cuts in wooden furniture pieces.

Signage and Advertising

Wooden signs, logos, and custom advertisements are often made using laser engraving and cutting for a clean, professional look.

Crafts and Gifts

Personalized wooden items, including gifts, trophies, and keepsakes, are created through laser engraving and cutting.

Toys and Games

Wooden toys, puzzles, and game boards are commonly produced using laser cutting and engraving techniques.

Architecture and Model Making

Laser cutting is used in creating architectural models and detailed miniature structures.

Musical Instruments

Laser engraving is used to add designs to wooden musical instruments, such as guitars or pianos.

Educational Tools

Laser cutting and engraving are often used to create educational models and materials made of wood.