Who are we?

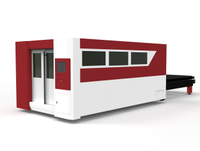

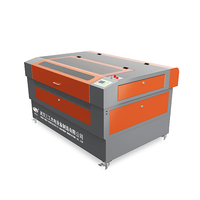

Wuhan Sunic Photoelectricity Equipment Manufacture CO., LTD, located at Eastern Lake high-tech district(Optics Valley), is a high technology innovation enterprise recognized by the Chinese government. It is authorized by the government to be in charge of the "863 Project" with privilege in importing and exporting. The company is dedicated to the R&D, production, selling and service in Laser processing equipment and solar energy equipment sets.It provides the customers with complete practical solutions in this field. Today, Sunic is China's leading professional photoelectricity equipment manufacturer in Laser processing equipment with the most complete product line, widest application.

Location: WuHan,China |

Established: Since 1998 |

Customers: 4000+ |

Gobal Agents: 50+ |

Site area: 60,000 ㎡+ |

Machine types: 40+ |

WHY CHOOSE US?

Argus After-Sales

1-year warranty |

24 hours online |

Free training |

Free manual |

Fast delivery |

Quality guarantee |

Installation guide |

Contact us at any time |

Corrective maintenance |

Technical team |

PRODUCT SHIPPING

MARKET FEEDBACK