Machine features

The precision fiber metal laser cutting machine adopts ultra-high precision linear motor module, compact structure and low power loss. Without mechanical contact, friction force is smaller. Smooth movement, high position accuracy and re-positioning accuracy, higher speed and acceleration. Fast reaction speed, high sensitivity, excellent follow-up performance, safe and reliable, long service life, low motion noise.

Technical parameters

| Model | SFC-3015H |

| Laser type | Fiber laser, 1080nm |

| Laser power | 1000w / 1500w / 2000w / 3000w/6000w |

| Working area | 3000 x 1500 mm |

| Min Line width | 0.1mm |

| Positioning accuracy | 0.03mm |

| Max. Cutting speed | 30m/min |

| Transmission type | Precision dual ball screw transmission |

| Driving system | Serve motors |

| Cutting thickness | Depending on laser power and material |

| Assisting gas | Compressed air, oxygen and nitrogen |

| Cooling mode | Industrial circulation water chiller |

| Visual positioning | Red dot |

| Working voltage | 220V/380V |

| Machine dimensions/Net Weight | 1800*1550*1840mm/1500kg |

| Packing dimensions/Gross Weight | 2550*1550*2000mm/1700kg |

Video

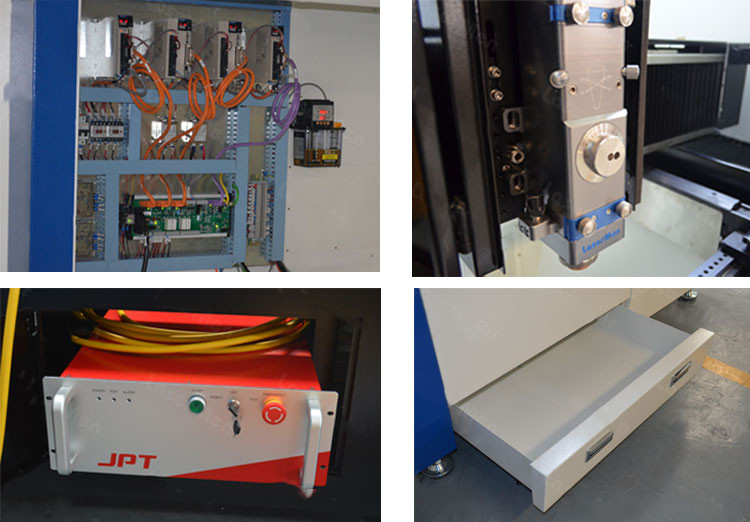

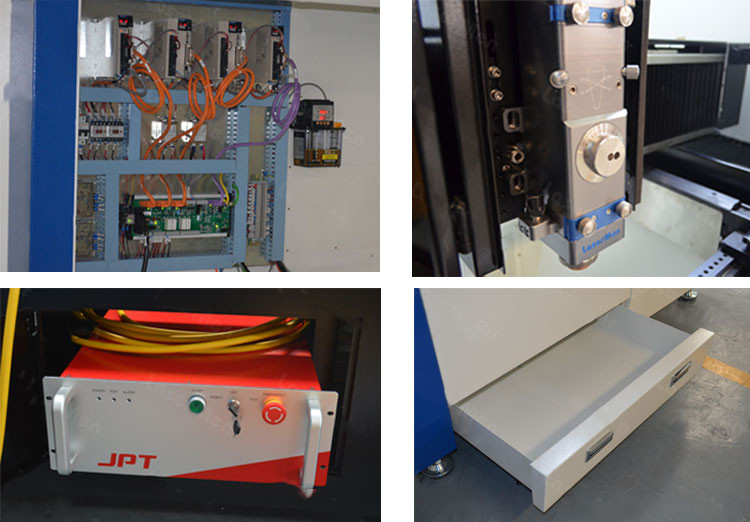

Machine Details

1. Top brand JPT / Yongli / Raycus fiber laser source 1000w / 1500w / 2000w / 3000w.

2. Professional laser cutting head with auto following system

3. Water chiller, it is able to cool the fiber laser and optic lenses at the same time

4. Adopting marble countertop, high precision, low linear expansion coefficient; no rust, easy to maintenance.

5. Air jig makes position more accurate, cutting parts use air jig to fix cutting materials and improve position accuracy. Suitable for thin plate, the thinnest plate it can hold is 0.3mm plate, improving the machining precision.

6. CypCut laser cutting control system, include control board , height control and machine software in English. Supporting files: DXF, PLT, AI, LXD, etc. Drawing in the software is also ok

7. Ball screw and linear rail transmission, which ensures machine high speed movement, precision and stability as well.

8. Japanese YASKAWA servo motors and drivers

9. Auto lubrication.

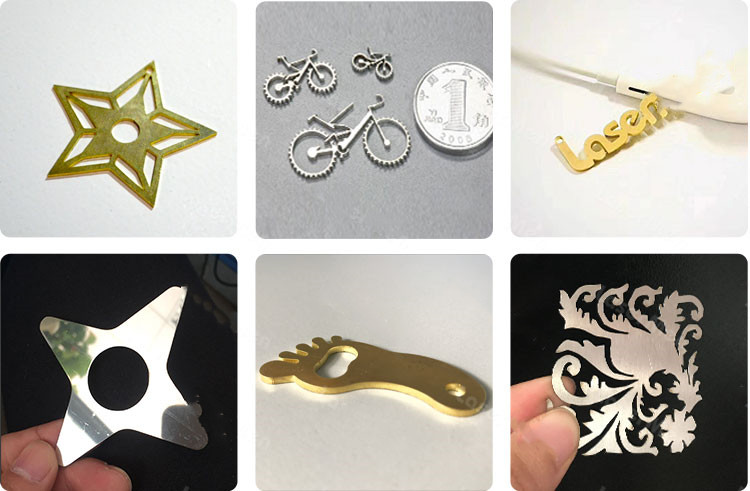

Machine Application