- Home

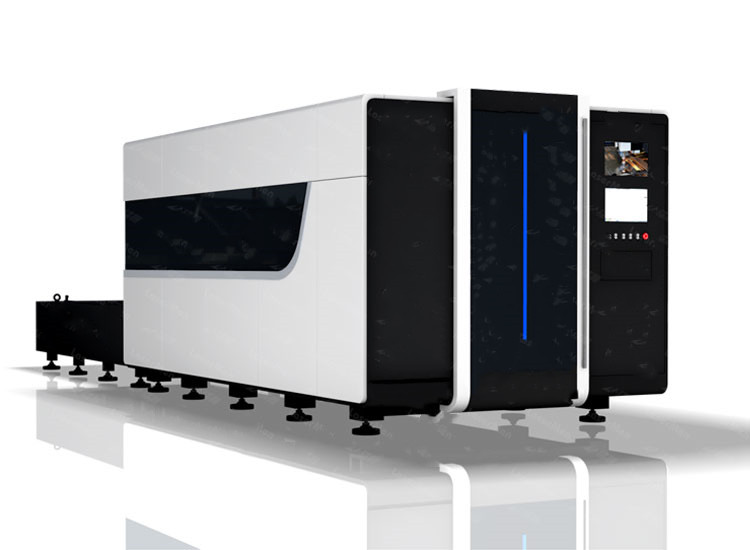

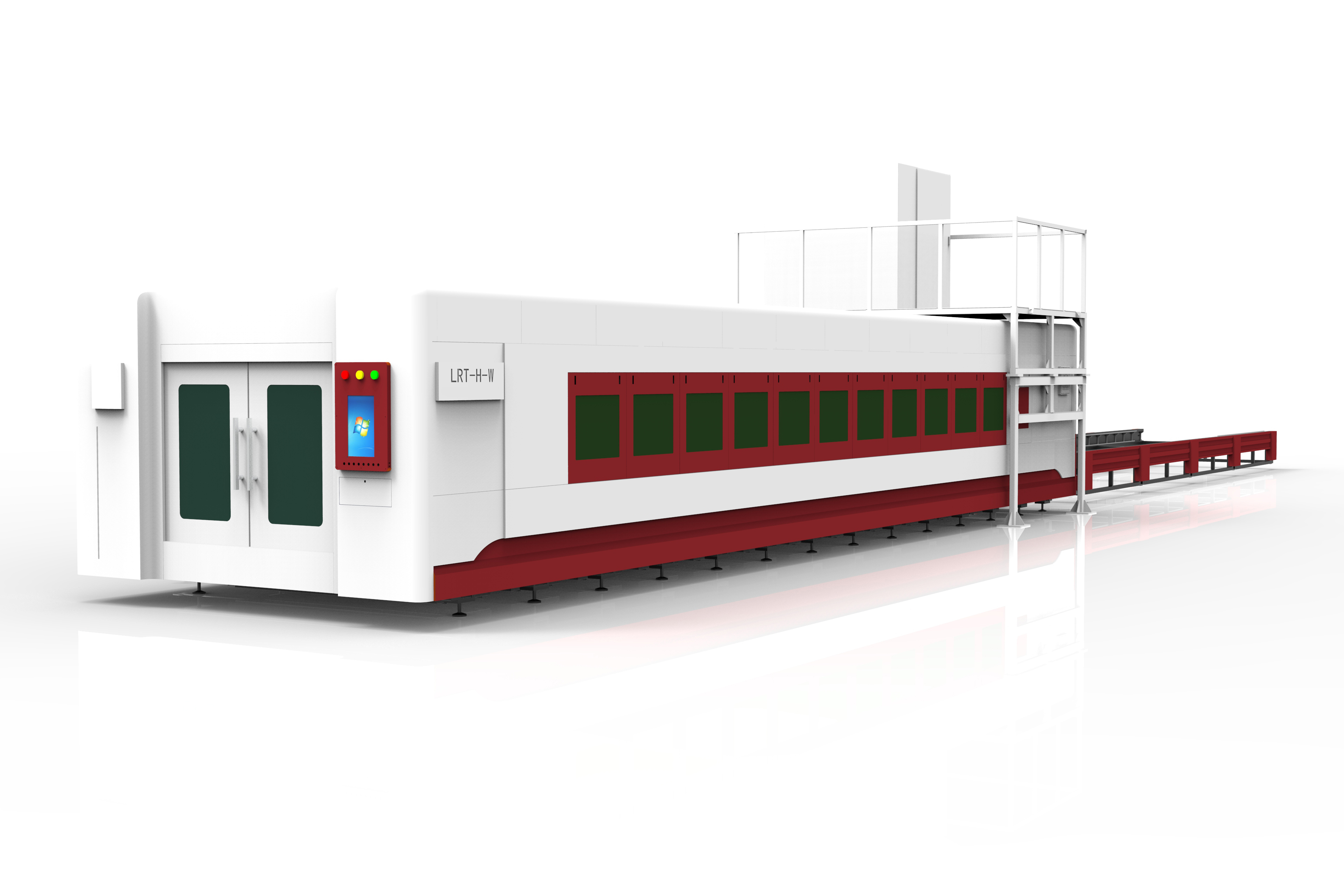

- Laser Machine

- Application

- Application Industry

- Acrylic advertising medal laser cutter

- Jeans Denim Laser system solution

- Flexible Packaging Perforation and Scoring

- Fabric/Textile Industry Cutting

- Customized Gifts Laser Machine

- Heat Transfer Film/Vinyl Machine

- Arts and Crafts Laser Engraver

- Games and Toys Laser Cutter

- Laser Architectural Model Making

- LGP Light Guild Plate Laser Dotting

- Metal Laser Marking and Engraving

- Materials

- All-in-One Laser Solutions

- Laser Technology

- About ARGUS

- Contact Us