Machine Type | ZKPC-100S/200S |

power supply | Standard equipped with Ac 110/220V±10%,

50/60Hz power adapter output DC48V |

Power consumption of the entire machine | ≤600W |

Working environment temperature | 5 ℃~40 ℃ |

Average laser power | ≥100W |

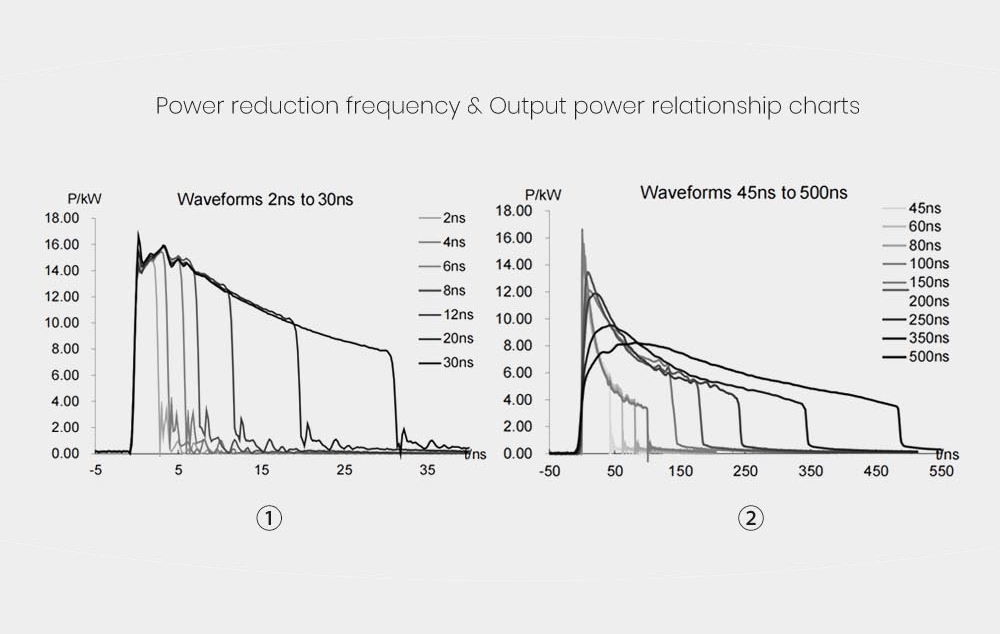

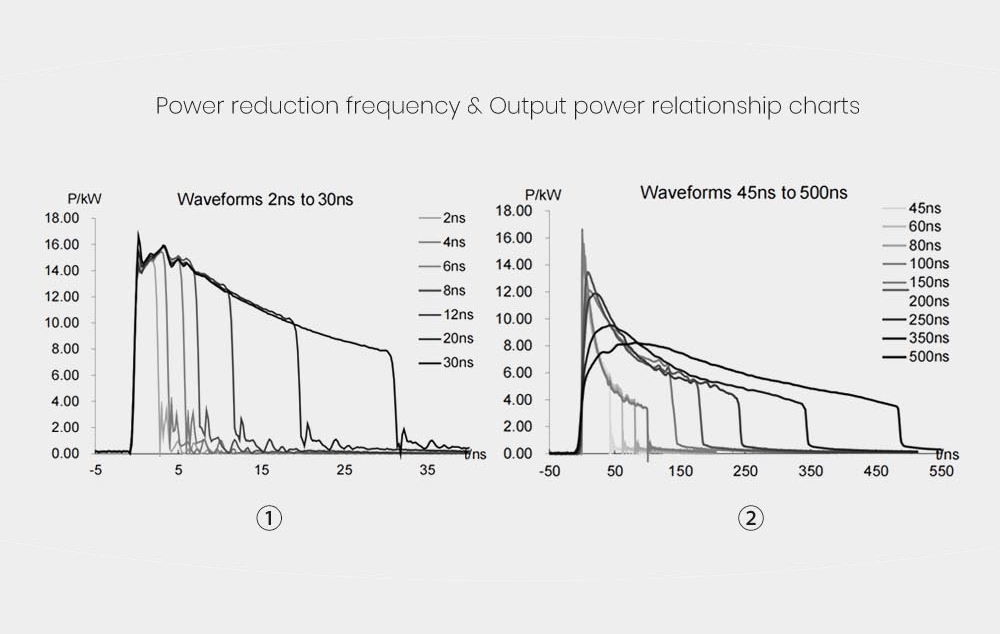

pulse width | 1-500ns |

Maximum single pulse energy | 1.7mJ |

Power regulation range (%) | 10-100 (gradient adjustable) |

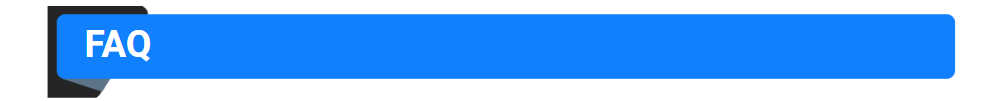

Scanning range (length * width) | F210,130mmx130mm;

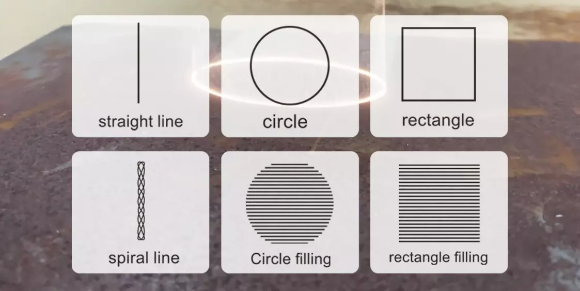

Dual-axis supports 9 scanning modes; |

Field mirror focal length (mm) | 230mm optional 210mm/254mm/330mm/420mm |

Depth of focus | About 5mm |

Host size (length, width, height) | Approximately 345mm*192mm*469mm

(Battery not included) |

Host weight (including cleaning head) | Approximately 17.3kg (Battery not included) |

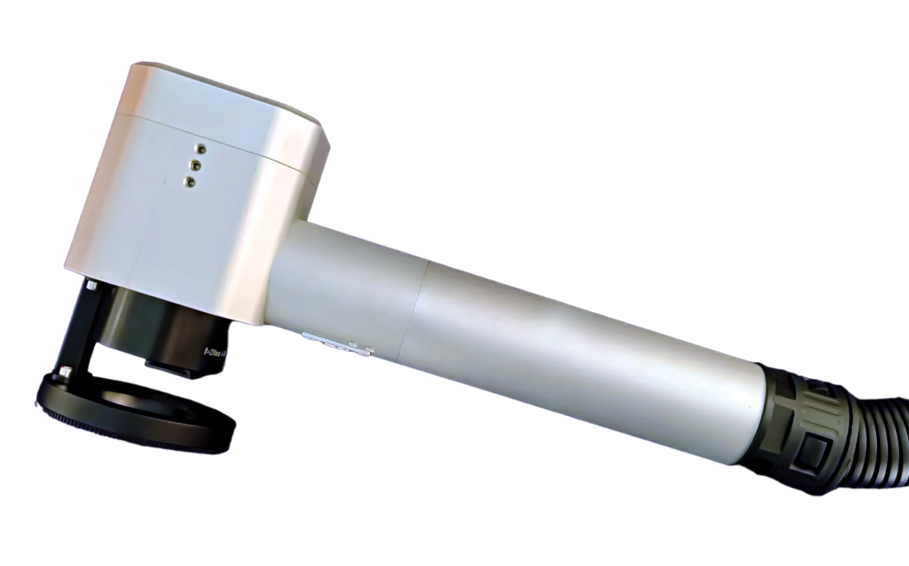

Weight of cleaning head | < 0.75Kg |

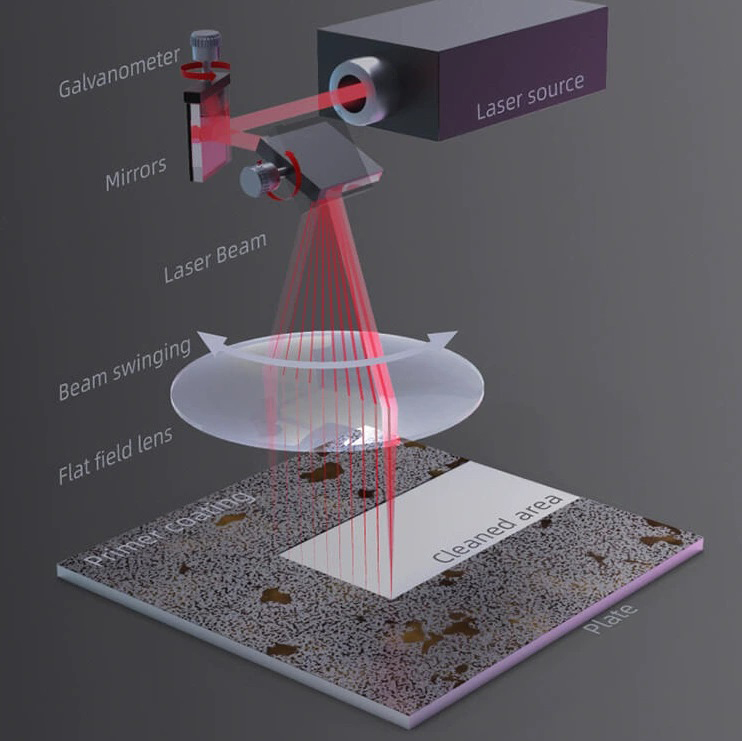

Laser Rust Cleaning Machine Function Introduction:

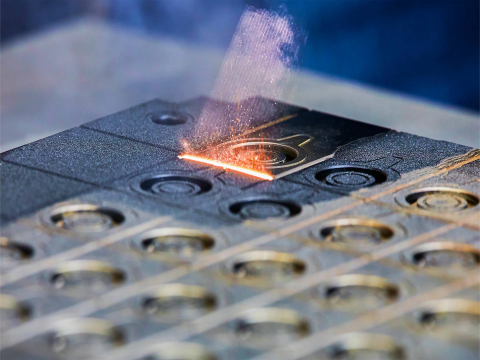

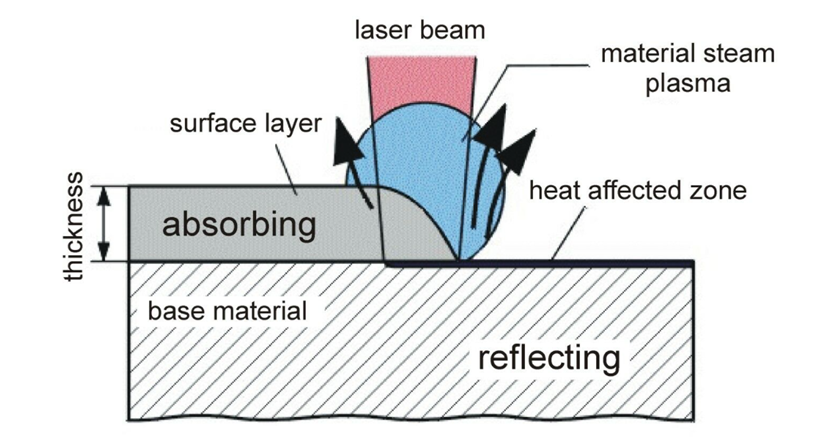

The laser cleaning machine can efficiently remove resin, oil stains, stains, dirt, rust, coating, plating, and paint on the surface of the work piece, meeting the cleaning requirements of complex shapes and fine positioning in the industrial processing field, achieving a cleaner cleaning effect with higher cleanliness, and a higher overall cost.

Tie rod Box Cleaner Super Portable Laser Rust Remover

Product advantages

1. Easy to carry

No external power supply, easy to carry, small size.

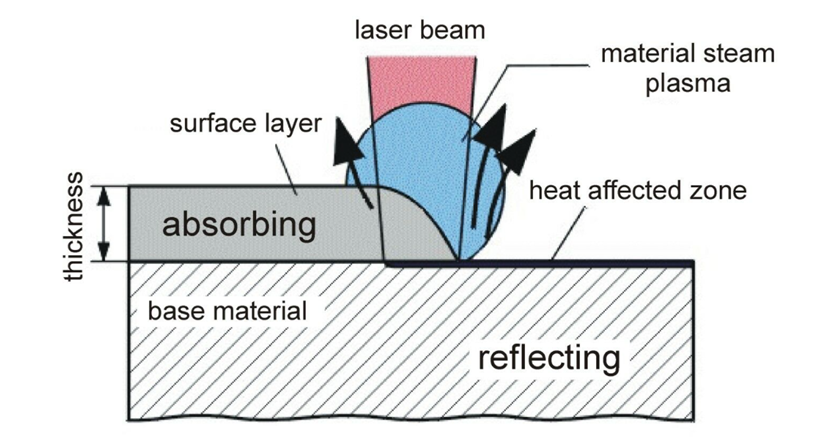

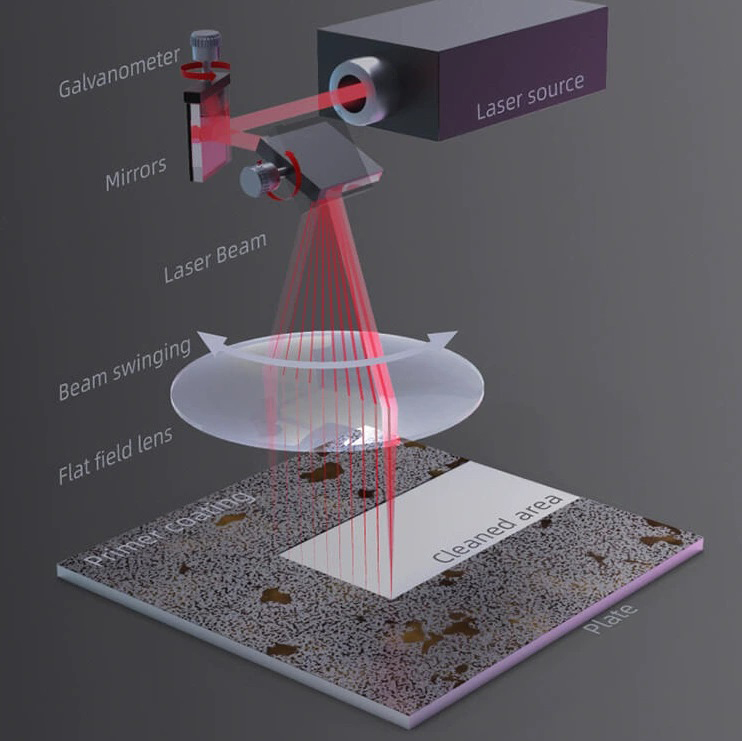

2. No damage to the material substrate

Non-contact cleaning,no damage to the material substrate, high-precision cleaning.

3. No pollution, safe and environmentally friendly

No chemical cleaning solution, no secondary pollution.

4. Blow protection device

The blow protection device is added to reduce the chance of damage to the field lens.

100W 200w portable fiber laser cleaning machine

For Rust removal, paint removal, oil removal, cultural relic restoration, glue removal, coating removal, etc.

1. No consumables, no chemical pollution, saving energy and electricity; 2. No contact, no friction, and no stress can protect the surface of brittle materials, and minimize damage to the substrate; 3. It can remove pollution particles below the nanometer level, and the cleanliness is high; 4. Optical fiber transmission can be moved and operated, precisely positioned for cleaning, and can also clean areas that are not easily accessible; 5. Synchronous cleaning and synchronous processing to achieve zero discharge during the cleaning process; 6. It can realize fast cleaning of heavy pollutants and high-speed cleaning of light pollutants; 7. Laser cleaning can solve problems that cannot be solved by traditional cleaning methods; 8. Wide range of applicable materials for laser cleaning;

How Much Does A Fiber Laser Cleaning Machine Cost?

The cost of handheld fiber laser cleaning machines varies greatly in accrodance with different laser power. A new fiber laser cleaner can cost from $4.4k to $13k. Specify your needs and get a quote for ARGUS fiber laser welder machine now.The delivery time is within 7 days.

The laser cleaning machine can efficiently remove resin, oil stains, stains, dirt, rust, coating, plating, and paint on the surface of the work piece, meeting the cleaning requirements of complex shapes and fine positioning in the industrial processing field, achieving a cleaner cleaning effect with higher cleanliness, and a higher overall cost.

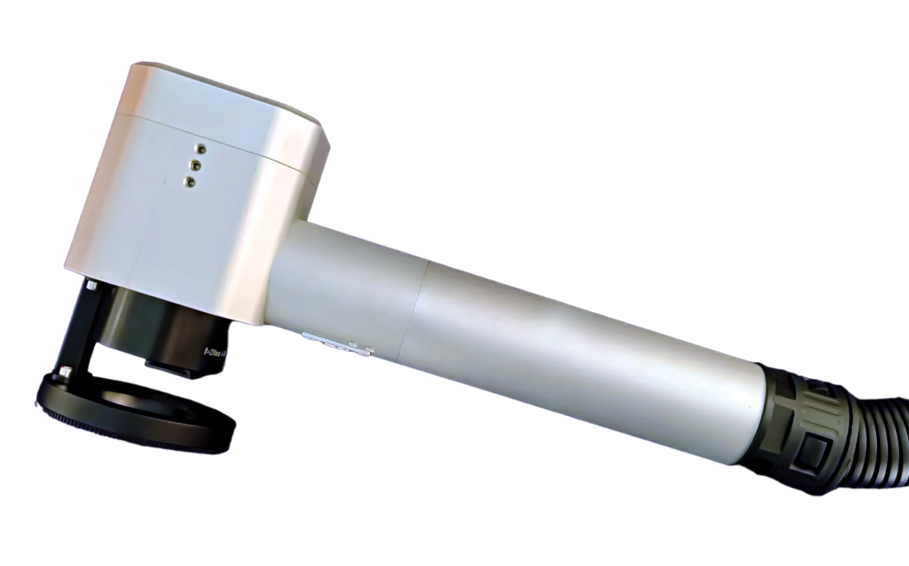

Cleaning Head

The weight is light, the body engineering design method is adopted, and the grip is comfortable. Its net weight is 0.7 kg.

Control System

Simple interface,Easy to use and operate. There are six languages you can choose, English,Korea,Spanish,and so on. Touch screen quick to change the parameters.

Laser Source

Raycus/MAX/IPG/JPT, multiple choice. Different brands, different laser power are available. Air cooling, which make you free from worrying about the freeze in winter. The machine could work in multiple environments.

Portable Silent Wheel

Unique widened and miniaturized design, more compact and beautiful, more stable, more convenient to move. Total weight 28kg, can be moved easily to anywhere you want to work at.

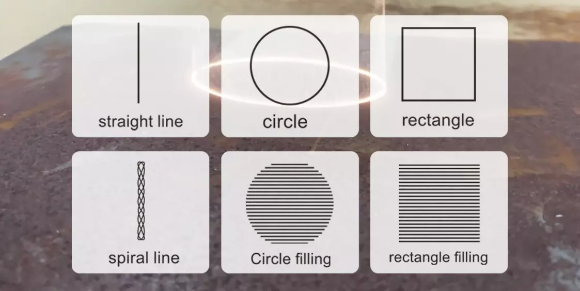

Cleaning modes

6 cleaning modes: Linear mode, rectangular mode, circular mode, sinusoidal mode, double helix mode, free mode. Different modes suitable for working on different materials with different cleaning requirements.

00:01

00:01

02:39

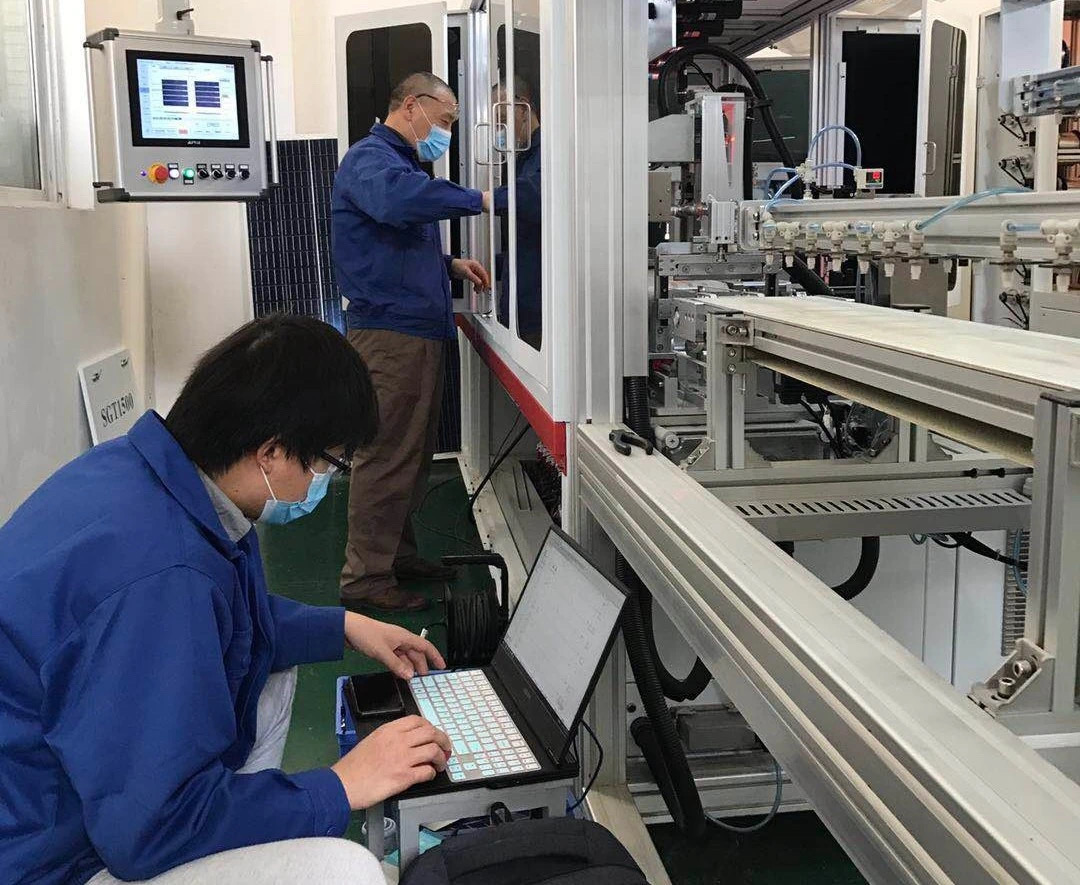

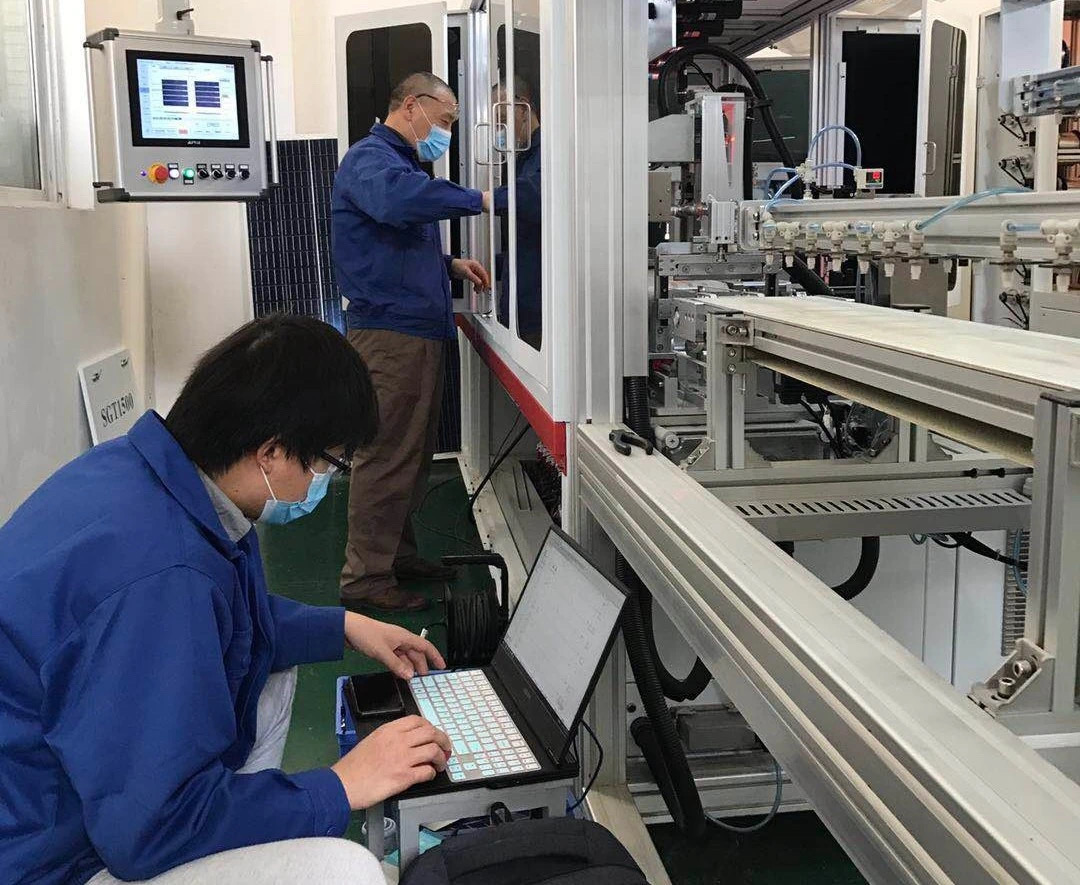

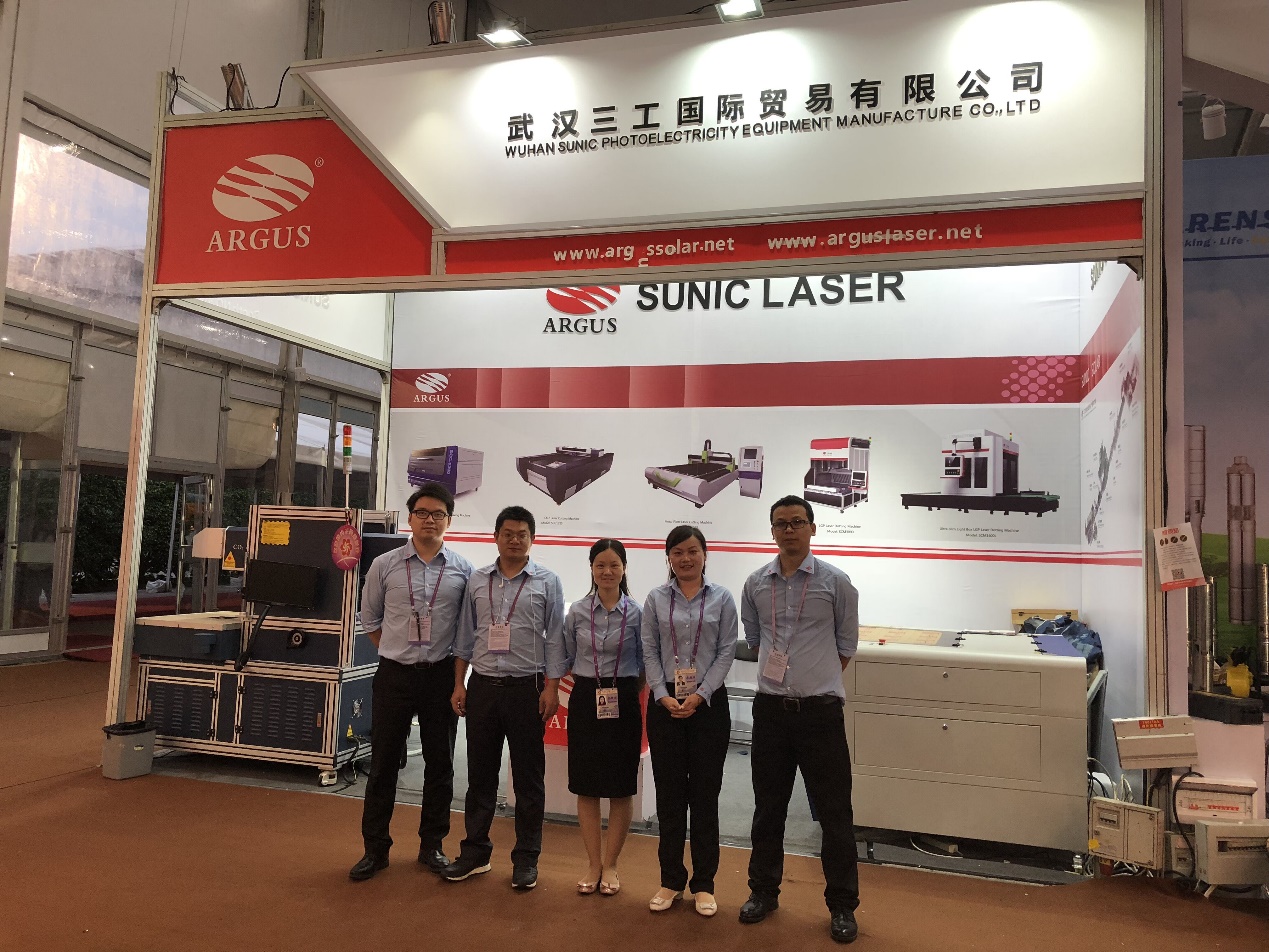

ABOUT SUNIC GROUP

Wuhan Sunic Group is a professional laser machines and solar panel products lines equipments manufacturer since 1998. We are specialized in Design, R&D, Manufacture, Sales and Service for laser machines.

We supply customized solution for different materials processing , such as Invitation cards, Wedding cards, Pop up cards, Pop up books , Candy box , Paper products, Acrylic , PMMA, LGP, Jeans Wash, Leather, Fabric, Textiles, Wood, MDF, Laminate materials , Marble, Package Film, Metal / Plastic products, etc.

Our laser equipment is widely used in Solar Photovoltaic production line, IC Component Production, Leather&Garment Industry, Advertising Signs, Decoration crafts, Equipment spare parts, Daily hardware, Measurement tools, Medical instruments, Printing&packing industries, etc. Sunic Group would like to be customer's technical laser and solar equipment consultation and support for further development and progress together.

What kind of laser machine and model should I choose?

You can tell us your processing material, working size and detail requirement, detail work by picture or video so that we can judge whether our machine can meet your need

What kind of materials does the laser machine can process?

We have different laser machines, such as Fiber laser, CO2 Laser, UV Laser Green Laser. Normally Fiber laser can process metal and plastic. CO2 laser is for processing non metallic materials, such as Acrylic, PMMA,Wood, Glass, Leather,Jeans, Paper, Textiles Garments and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass, crystal and some special processing job.

Is it easy to operate?

We will send you manual and guide video in English, I can teach you how to operate the machine. lf you still can not learn how to use it, we can help you by Team viewer online help software.Or we can talk by phone email or other contact ways.

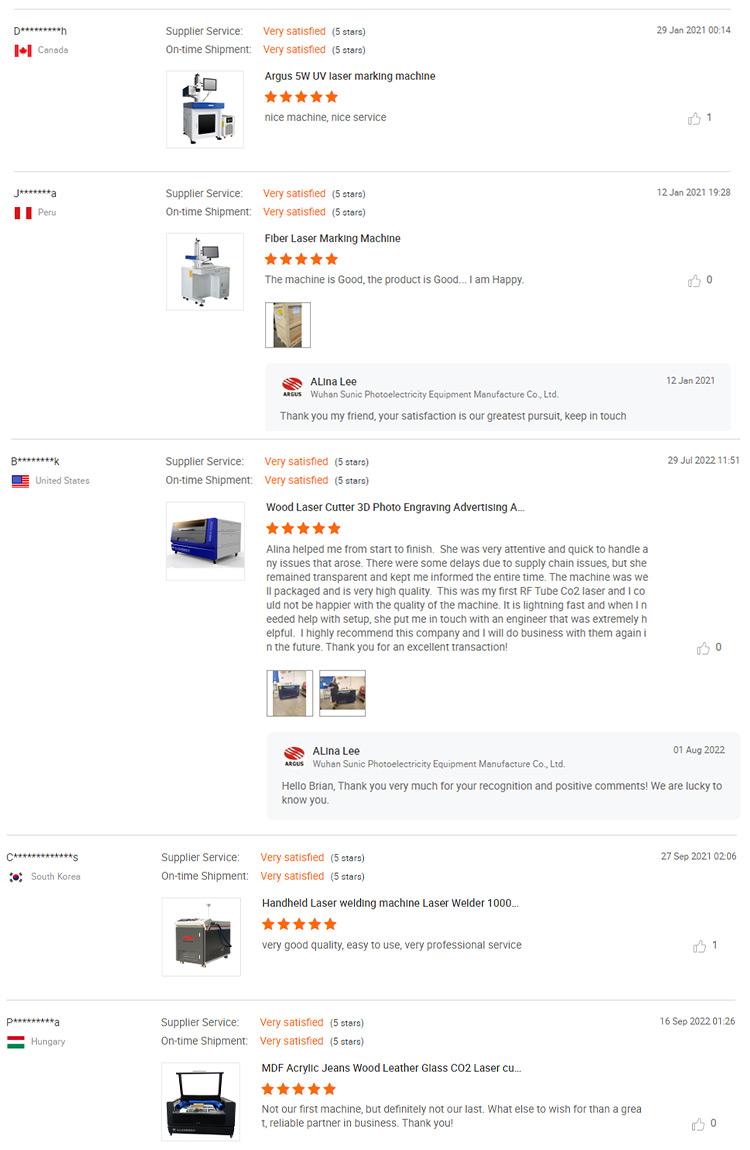

What s your guarantee. in case the machine breaks down?

The machine has one year guarantee. If it breaks down, generally speaking our technician will figure out what the problem may be, according to client's feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

How will you do the after- sale service?

We will firstly check your problems online through Team viewer,E-mail, Whatsapp or other contact way, if it is easy to handle it, we will guide you online to fix it or send you the spare parts for replacement.

What is your equipment lead time?

Fiber laser marking machine lead time is around 7 working days. CO2 laser engraving&cutting machine lead time is around 2-3 weeks 3D dynamic CO2 laser marking machine lead time is around 10 working days.

How will you do the package and shipping?

All of our equipment are packed in export standard cases. Express, air shipping, sea shipping are all available.