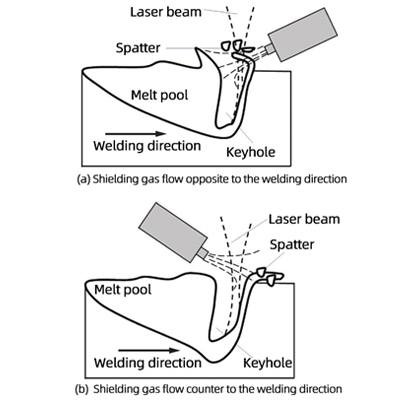

The Influence of Shielding Gas Parameters on Laser Welding Process hielding gas selection—including type, flow rate, and delivery method—is critical for controlling oxidation, porosity, and energy transfer in laser welding.

Inert gases like helium and argon offer different advantages in weld penetration and cooling, while active gases require precise control to avoid defects.

Proper gas flow and delivery strategies significantly enhance weld quality, especially for materials like stainless steel, carbon steel, and aluminum alloys.