01 Introduction

Laser welding technology, due to its high energy density, low heat input, and non-contact characteristics, has become one of the core processes in modern precision manufacturing. However, problems such as oxidation, porosity, and element loss caused by the molten pool's contact with the atmosphere during welding severely limit the mechanical properties and service life of the welds. Shielding gas, as the core medium for controlling the welding environment, requires careful selection of its type, flow rate, and gas delivery method, which must be coupled with material characteristics (such as chemical reactivity and thermal conductivity) and plate thickness.

02 Types of Shielding Gas

The core function of shielding gas is to isolate oxygen, regulate molten pool behavior, and improve energy coupling efficiency. Based on their chemical properties, shielding gases can be divided into inert gases (argon, helium) and active gases (nitrogen, carbon dioxide). Inert gases, with high chemical stability, effectively prevent molten pool oxidation, but their significant differences in thermal-physical properties can affect welding outcomes. For example, argon (Ar), with a high density (1.784 kg/m³), can form a stable covering layer, but its low thermal conductivity (0.0177 W/m·K) results in slow molten pool cooling and shallow weld depth. In contrast, helium (He) has a thermal conductivity eight times that of argon (0.1513 W/m·K), which can accelerate molten pool cooling and increase weld depth, but its low density (0.1785 kg/m³) causes it to dissipate easily, requiring higher flow rates to maintain effective protection. Active gases such as nitrogen (N₂) can enhance weld strength through solid solution strengthening in certain situations, but excessive use can cause porosity or brittle phase precipitation. For instance, during welding of duplex stainless steel, nitrogen infiltration into the molten pool can disrupt the ferrite/austenite phase balance, leading to reduced corrosion resistance.

From a process mechanism perspective, the high ionization energy of helium (24.6 eV) can suppress plasma shielding effects, improving laser energy absorption and thus increasing weld depth. Conversely, the low ionization energy of argon (15.8 eV) makes it prone to generating a plasma cloud, requiring defocusing or pulsed modulation to reduce interference. Moreover, the chemical reactions between active gases and the molten pool (such as nitrogen reacting with chromium in steel to form nitrides) can alter the composition of the weld, so careful selection must be made based on material characteristics.

Material Application Examples:

• Steel: For thin sheet welding (<3 mm), argon can ensure surface smoothness, as seen in a 1.5 mm low-carbon steel weld, where the oxide layer thickness is only 0.5 μm. For thicker plates (>10 mm), a small amount of helium (He) is needed to increase weld depth.

• Stainless Steel: Argon protection prevents chromium loss, and the Cr content in a 3 mm thick 304 stainless steel weld reaches 18.2% (close to the base material’s 18.5%). Duplex stainless steel requires an Ar-N₂ mixed gas (N₂ ≤ 5%) to balance phase ratios. Studies show that when an Ar-2%N₂ mix is used for welding 8 mm thick 2205 duplex stainless steel, the ferrite/austenite phase ratio stabilizes at 48:52, and tensile strength reaches 780 MPa, outperforming pure argon protection (720 MPa).

• Aluminum Alloy: For thin sheets (<3 mm), aluminum alloy’s high reflectivity leads to low energy absorption, but helium, with its high ionization energy (24.6 eV), stabilizes the plasma. Studies show that when 2 mm thick 6061 aluminum alloy is protected with helium, the weld depth reaches 1.8 mm, 25% higher than argon, with a porosity rate of less than 1%. For thick plates (>5 mm), high energy input is required. A helium-argon mixture (He:Ar = 3:1) balances weld depth and cost. For example, when welding 8 mm thick 5083 plates, the mixed gas protection results in a weld depth of 6.2 mm, 35% higher than pure argon, and reduces welding costs by 20%.

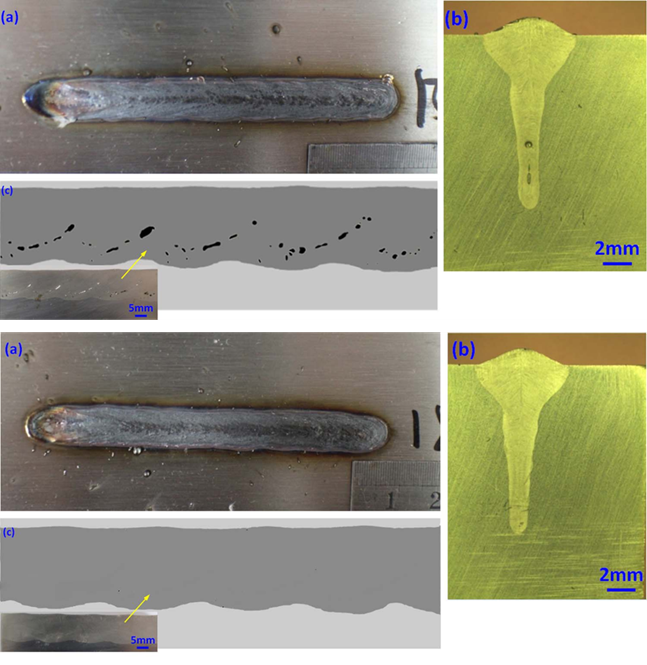

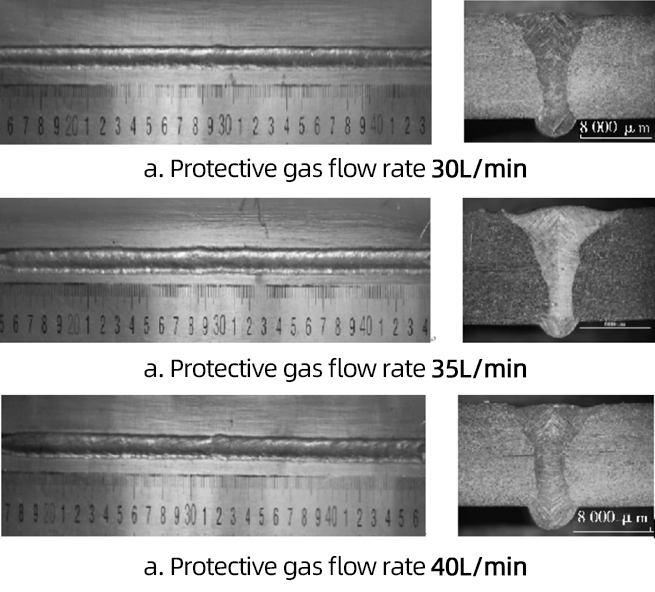

03 Influence of Shielding Gas Flow Rate

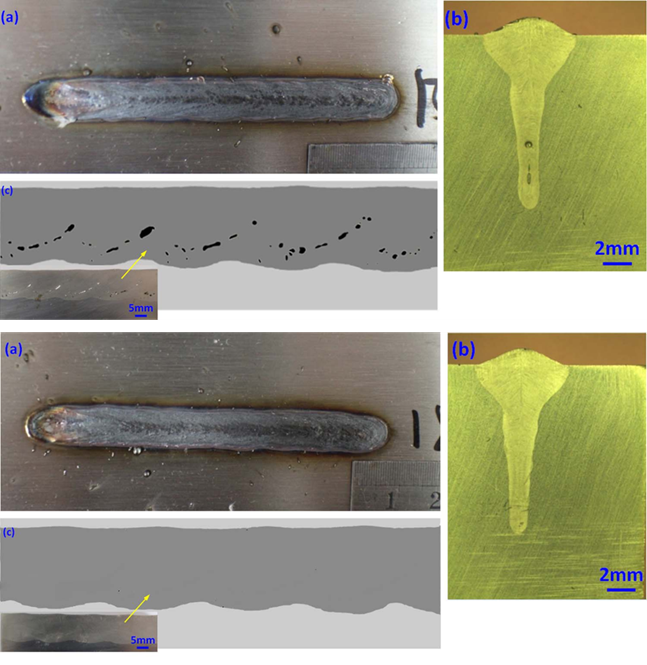

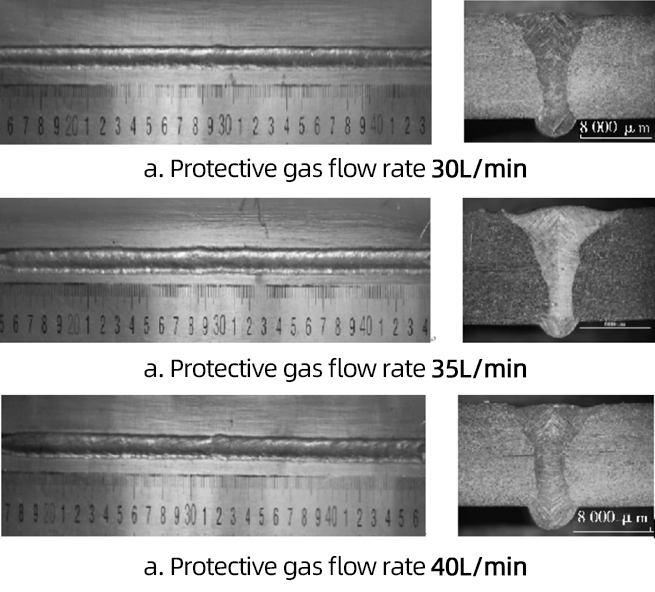

The flow rate of shielding gas directly affects its ability to cover the molten pool and its fluid dynamics. When the flow rate is insufficient, the gas layer cannot completely isolate the air, causing oxidation at the edges of the molten pool and the formation of porosity. If the flow rate is too high, turbulence may occur, sweeping the molten pool surface and causing weld bead depression or spattering. According to fluid mechanics Reynolds number (Re = ρvD/μ), as the flow rate increases, the flow velocity increases, and when Re > 2300, laminar flow becomes turbulent, disrupting molten pool stability. Therefore, determining the critical flow rate requires experimental or numerical simulation (such as CFD) analysis.

Flow rate optimization must be adjusted based on material thermal conductivity and plate thickness:

• Steel and Stainless Steel: For low-carbon steel thin sheets (1-2 mm), the flow rate should be 10-15 L/min. For thicker plates (>6 mm), it needs to be increased to 18-22 L/min to suppress tail oxidation. For example, with a flow rate of 20 L/min for 6 mm thick 316L stainless steel, the hardness uniformity in the heat-affected zone (HAZ) improves by 30%.

• Aluminum Alloy: Due to its high thermal conductivity, a higher flow rate is required to extend the protection time. For 3 mm thick 7075 aluminum alloy, the flow rate should be 25-30 L/min to achieve the lowest porosity rate (0.3%), but for ultra-thick plates (>10 mm), composite gas delivery should be used to avoid turbulence.

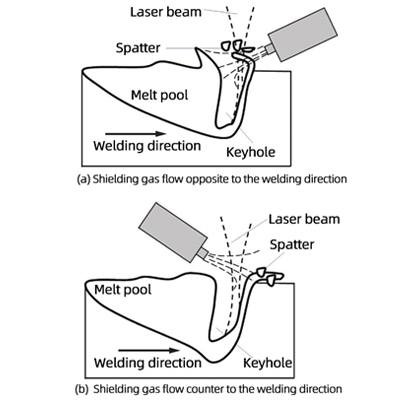

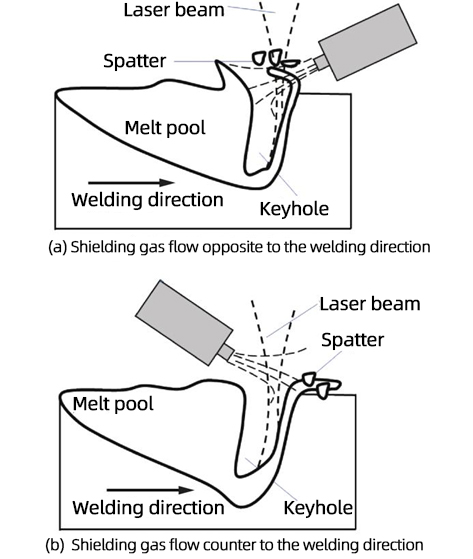

04 Influence of Shielding Gas Delivery Method

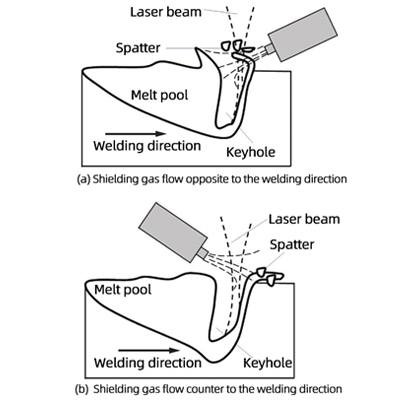

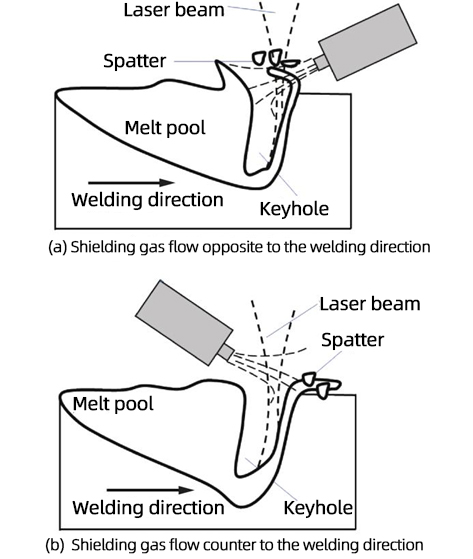

The gas delivery method directly affects the molten pool flow pattern and defect suppression by controlling the gas flow direction and distribution. The delivery method adjusts the molten pool's flow by altering surface tension gradients and Marangoni flow. Lateral gas delivery can direct the molten pool flow in a specific direction, reducing porosity and slag inclusions, while composite gas delivery balances energy distribution to improve weld formation uniformity.

Main delivery methods include:

• Coaxial Delivery: The gas flow is co-axial with the laser beam, symmetrically covering the molten pool, suitable for high-speed welding. Its advantage is high process stability, but the gas flow may interfere with the laser focus. For instance, with coaxial delivery on a 1.2 mm galvanized automotive steel sheet, the welding speed increases to 40 mm/s, with spatter <0.1%.

• Lateral Delivery: The gas flow is directed from the side of the molten pool, which can clear plasma or impurities from the bottom, suitable for deep welds. For example, with lateral gas flow (30° angle) on 12 mm thick Q345 steel, the weld depth increases by 18%, and the bottom porosity rate drops from 4% to 0.8%.

• Composite Delivery: Combining coaxial and lateral delivery, this method simultaneously suppresses oxidation and plasma interference. For example, with a dual nozzle design on 3 mm thick 6061 aluminum alloy, the porosity rate drops from 2.5% to 0.4%, and tensile strength reaches 95% of the base material.

05 Conclusion

The influence of shielding gas on welding quality essentially stems from its regulation of energy transfer, molten pool thermodynamics, and chemical reactions:

Energy Transfer: Helium’s high thermal conductivity accelerates molten pool cooling and reduces the heat-affected zone (HAZ) width, while argon’s low thermal conductivity prolongs the molten pool's existence time, benefiting surface formation in thin sheets.

Molten Pool Stability: Gas flow impacts molten pool movement through shear forces, and an optimal flow rate can suppress spattering. Excessive flow rate, however, induces vortexes, leading to weld defects.

Chemical Protection: Inert gases isolate oxygen, preventing oxidation of alloy elements (e.g., Cr, Al); active gases (e.g., N₂) alter weld properties through solid solution strengthening or compound formation, but their concentration must be carefully controlled.

**--Cite the article published by 高能束加工技术 on March 14, 2025, in the WeChat public account "High-Energy Beam Processing Technology and Applications."