01 Introduction

Coffee is one of the most popular beverages worldwide, and moderate consumption offers various health benefits. The main active compound in coffee, caffeine, stimulates the central nervous system, helping to boost alertness, reduce fatigue, and improve concentration. Traditionally, coffee is brewed by extracting roasted and ground beans with hot water, but alternative methods such as cold brew have gained popularity in recent years. High temperatures quickly dissolve a wide range of soluble compounds from coffee beans, including acids, oils, and aromatic compounds, with extraction typically completed in a few minutes. However, high temperatures also extract more bitter and acidic compounds. In contrast, cold extraction is performed at room or lower temperatures and proceeds slowly, primarily dissolving more readily soluble compounds. Compared to hot brewing, cold extraction results in much less acidic and oily content but usually requires hours or even days to complete.

To prepare cold brew coffee within minutes, researchers have proposed a method utilizing ultrashort pulsed lasers to brew solids without heating the powder suspension in water, effectively extracting caffeine and aromatic substances. After 3 minutes of laser irradiation at room temperature, the caffeine concentration reached 25 mg per 100 mL, comparable to traditional hot-brewed coffee, without heating the suspension. Furthermore, reverse-phase liquid chromatography coupled with high-resolution mass spectrometry analysis showed that the alkaloid content in the liquid was mainly caffeine and trigonelline, similar to conventional cold brew coffee rather than hot brew.

02 Application Principle

The extraction method for cold brew coffee is based on an extension of Laser Synthesis and Processing of Colloids (LSPC) technology, which involves laser interactions with liquids (typically colloidal solutions or suspensions containing precursors or particles) to synthesize new nanoparticles or modify existing ones. One approach in LSPC is Laser Post-Processing (LPP) of particle suspensions, aiming to modify or change existing particle properties, such as fragmentation induced by thermal or electronic processes, depending on laser parameters like wavelength, pulse duration, repetition rate, and pulse energy.

When using picosecond lasers, energy is delivered so quickly that it acts before heat diffusion occurs, greatly reducing chemical decomposition or degradation of organic substances, with degradation rates (<2%) comparable to traditional grinding. Since the energy input happens before heat transfer to the surrounding water or internal particles, the macroscopic temperature of the liquid remains unchanged, maintaining cold extraction conditions.

In simpler terms, traditional cold brewing is like dissolving a sugar cube slowly in cold water, requiring a long time. Hot brewing is like using hot water to dissolve sugar quickly but alters the taste. Picosecond laser cold extraction is like using an extremely fast, precise “energy hammer” to instantly break the sugar cube into tiny particles in cold water, allowing rapid dissolution without heating, preserving the original flavor more accurately.

03 Graphical Analysis

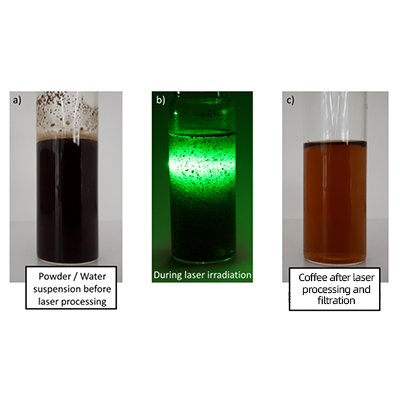

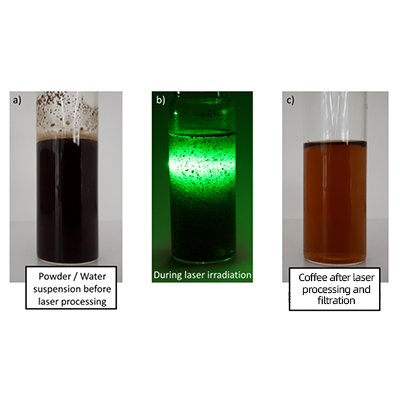

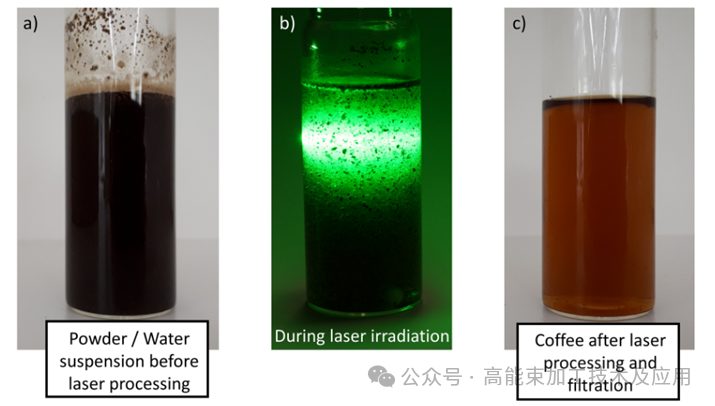

After filtration, pulsed laser-fragmented (laser-extracted) coffee powder forms a brown suspension in pure water. Figures 1a–c show coffee along the laser irradiation process chain. After 3 minutes of ps-laser irradiation, the temperature rose only by 5±3°C, making the temperature change negligible and closely mimicking the cold brew process.

Longer pulse durations, however, would cause temperature increases and expected compositional changes such as degradation, making them unsuitable for the cold brew laser extraction proposed here.

Figure 1. Ultrashort pulse laser extraction process for coffee: a) Coffee powder suspended in water; b) Coffee powder suspended under laser irradiation; c) The final product after 3 minutes of laser irradiation and subsequently filtered through a coffee filter.

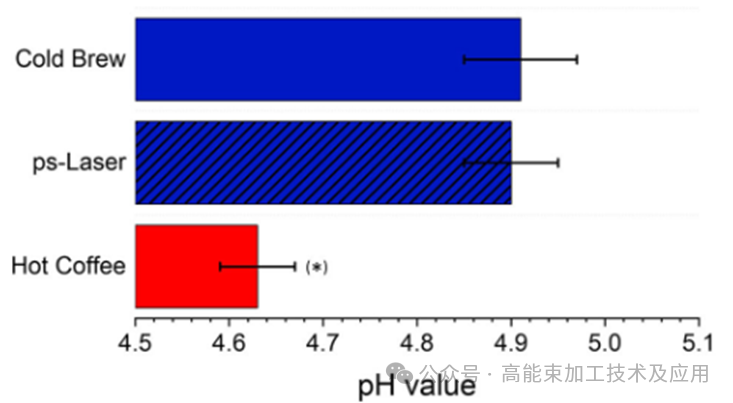

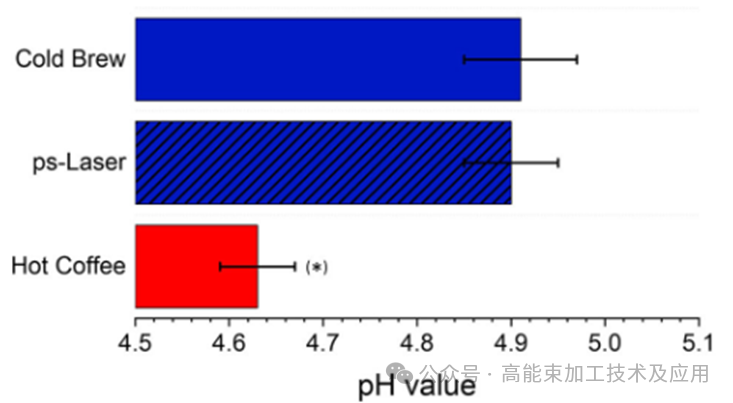

Lower acidity is a hallmark of cold brew coffee, and the LPP brewing process's effect on pH was evaluated.

Figure 2. pH of brewed coffee measured using different methods.

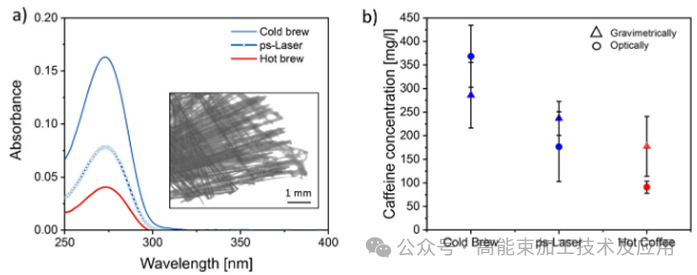

In actual preparation, cold brew coffee typically uses a higher coffee-to-water ratio than hot brew. The study followed this practice, using double the coffee concentration for cold brew and ps-laser extraction compared to hot brew, ensuring an absolute content comparison between cold brew and laser-extracted coffee.

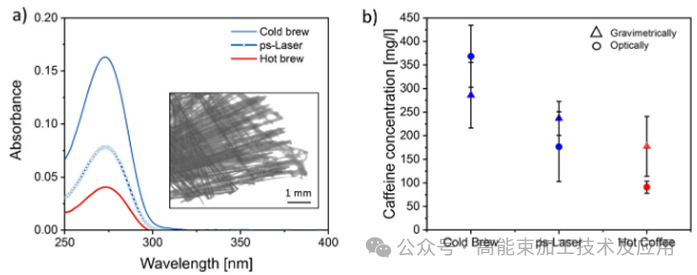

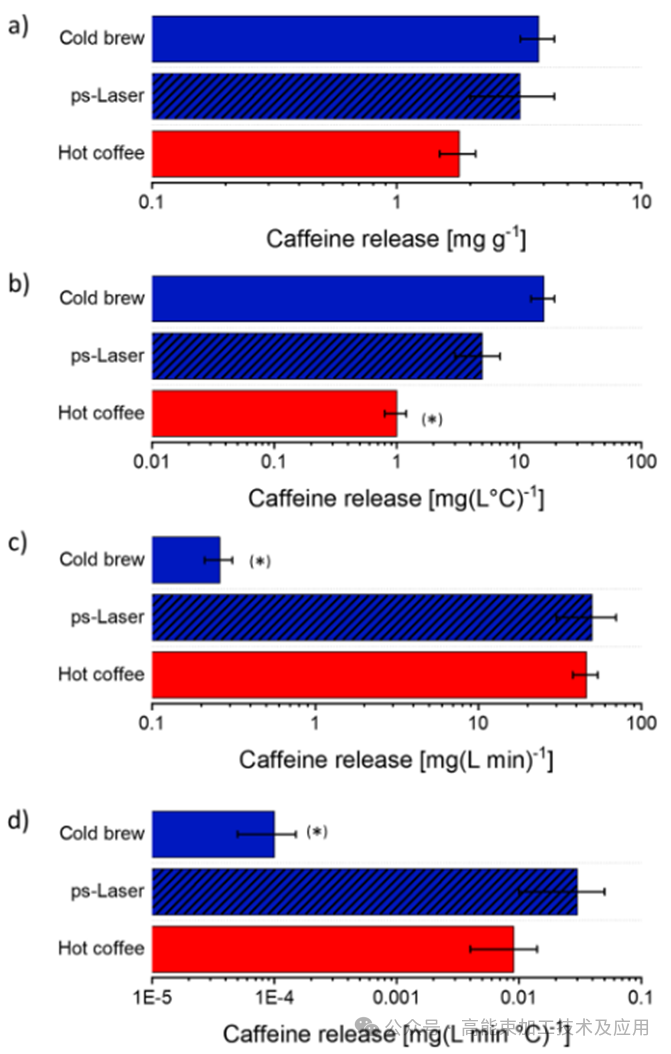

Figure 3 shows that cold brew coffee had the highest absolute caffeine concentration, with ps-laser-extracted coffee slightly lower and comparable to hot brew coffee.

Figure 3. Caffeine content measured by UV-Vis spectroscopy.

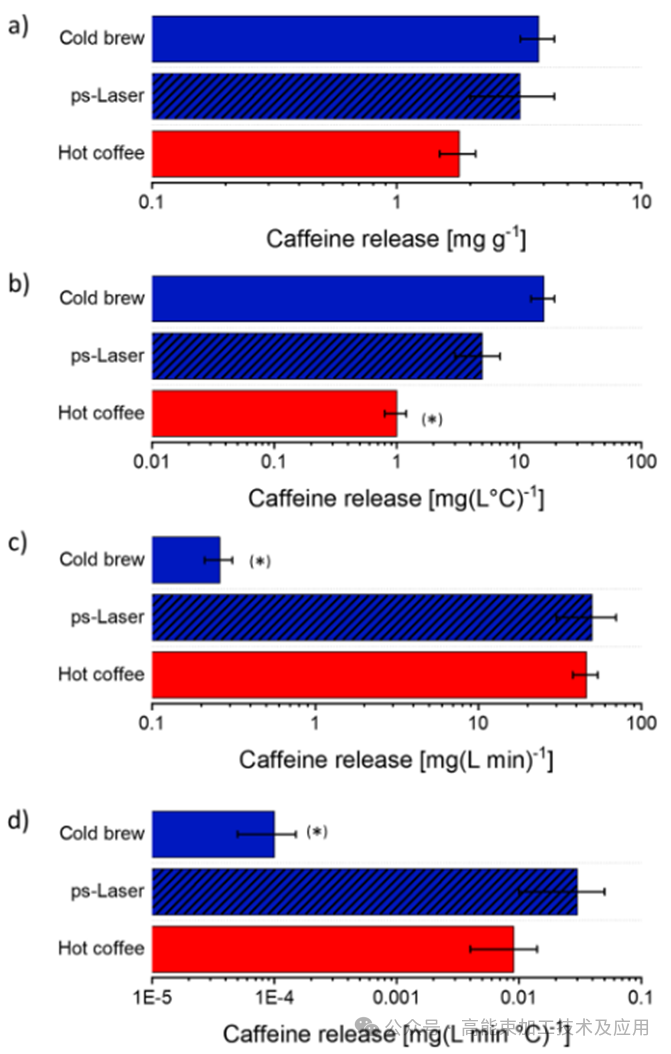

To fairly compare different methods (hot brew, cold brew, ps-laser), factors such as coffee amount, extraction time, and water temperature were standardized.

After normalizing for coffee powder usage, no significant difference in caffeine extraction efficiency was observed among the three methods. When normalized for extraction temperature, cold brew showed significantly improved extraction efficiency. After time normalization, cold brew coffee's caffeine release rate was two orders of magnitude lower than the other two methods.

Figure 4 shows that, overall, picosecond laser extraction displayed the highest relative caffeine release efficiency, 3–5 times higher than cold brew and comparable to hot brew. From a caffeine extraction perspective, cold brew is inefficient as it requires more time and coffee powder.

Fig. 4. Comparison of caffeine extraction efficiency by cold extraction, hot extraction, and laser extraction. Caffeine release is calculated from the optically determined caffeine concentration and normalized to the coffee powder concentration: a) coffee powder concentration; b) temperature; c) process time; d) normalized to all parameters.

04 Conclusion

To address the traditionally long cold brew coffee preparation time (12–24 hours), researchers explored and validated an innovative solution using picosecond ultrashort pulsed laser technology.

This method physically fragments coffee particles in cold water using ps-laser post-processing, enabling extraction within about 3 minutes while maintaining a chemical composition (such as alkaloids and semi-volatile substances) highly similar to traditional cold brew, preserving the low-acid, low-bitter taste.

In particular, when normalized by time, the laser method outperformed traditional cold brew by approximately 300 times and hot brew by about 3 times in caffeine extraction efficiency. Although further chemical safety and sensory evaluations are needed before market adoption, this approach shows great potential for developing automated laser coffee brewing devices for instant cold brew flavor experiences.

(Source: https://doi.org/10.1038/s41538-022-00134-6)

**--Cite the article published by 高能束加工技术 on April 24, 2025, in the WeChat public account "High-Energy Beam Processing Technology and Applications."