Overview:

In the field of industrial manufacturing, laser marking technology plays a crucial role in achieving durable and precise markings on various materials. This article presents a comparative analysis of the black marking performance of three different laser sources—nanosecond, picosecond, and fiber lasers—on 316 stainless steel, with a focus on their performance under salt spray testing and scanning electron microscope (SEM) analysis.

Laser Marking Requirements for Stainless Steel

Characteristics and Advantages of Stainless Steel

Stainless steel is an alloy material composed of metals such as iron, chromium, nickel, and carbon, known for its resistance to weak corrosive media like air, steam, and moisture. Due to its excellent corrosion resistance, high-temperature resistance, high strength, and ease of processing, it has a wide range of applications in many industrial fields. Traditionally, when thinking of stainless steel marking, people might associate it with low-cost methods like traditional spray painting or fast stamping; however, these methods have obvious drawbacks, such as wear and peeling of markings, unclear contrast, and fading or discoloration. In high-precision industries with strict standards, these traditional marking methods cannot meet the requirements. Laser marking emerged as the solution, perfectly addressing the need for high-standard marking. When using ultrafast laser pulses, the markings have enhanced corrosion resistance. The extremely short duration of these pulses minimizes the heat-affected zone (HAZ), leaving sufficient free chromium on the surface. The remaining chromium forms an oxide layer that provides corrosion resistance. This technology offers significant advantages in industries such as medical devices, aerospace, automotive, and consumer electronics.

Laser Sources and Experimental Methods Involved

This experiment primarily evaluated three types of lasers:

FOTIA laser (nanosecond-UV-355nm)

AMT laser (picosecond-IR-1064nm)

Fiber laser (nanosecond-IR-1064nm)

Grid test samples were marked in black at different dot grid sizes, ensuring uniformity in the vertical and horizontal dot spacing. The fill spacing determines the vertical spacing, while the horizontal spacing is calculated based on the scanning speed divided by the repetition frequency. Corrosion resistance and passivation tests were conducted on samples, which underwent salt spray testing and ASTM A967 standard passivation testing. The salt spray test was performed using the BEMCO P700 tabletop salt spray chamber with a 5% salt solution at a constant temperature of 5 PSIG, lasting for 72 hours to simulate prolonged exposure to high pressure, high temperatures, and salt fog. The passivation test strictly followed the ASTM A967 standard, a specification for chemical passivation of stainless steel parts. The process removes free iron from the surface, forming a protective oxide layer that enhances the corrosion resistance of stainless steel.

Laser Sources and Experimental Methods Involved

1、L.a.b Value Contrast Test.

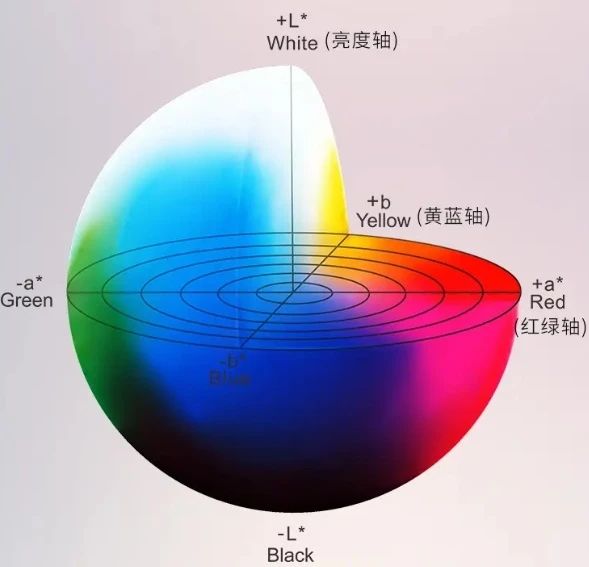

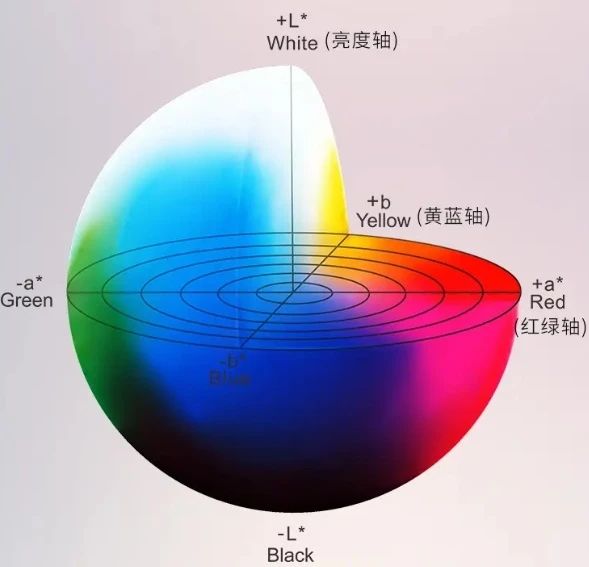

L.a.b value is a color space model consisting of three parameters:

L represents color brightness, with a range of [0-100] corresponding to [pure black -- pure white]

A represents the color axis from green to red, with a range of [-128 -- +127] corresponding to [green -- red]

B represents the color axis from blue to yellow, with a range of [-128 -- +127] corresponding to [blue -- yellow]

Both nanosecond lasers and ultrafast lasers can produce high-contrast black markings.

| L.a.b. Value Comparison | Ultraviolet (UV) | Infrared (IR) | Fiber Laser |

| L Value | 20.66 | 17.13 | 27.96 |

| A Value | 3.31 | 0.7 | 2.36 |

| B Value | 4.48 | 1.63 | 6.02 |

The L value represents darkness, with smaller values indicating darker shades. The A and B values represent the color range towards red-green and yellow-blue, respectively. The values closer to [0] indicate neutrality.

2、Experimental Results

In the laser black marking L.a.b. value test, the infrared picosecond laser produced the best black marking effect, generating the darkest and most neutral color. Next was the nanosecond ultraviolet laser, which produced relatively dark markings but with some color shift. The fiber laser showed average results, producing the brightest markings with the largest color shift, indicating lower blackness quality.

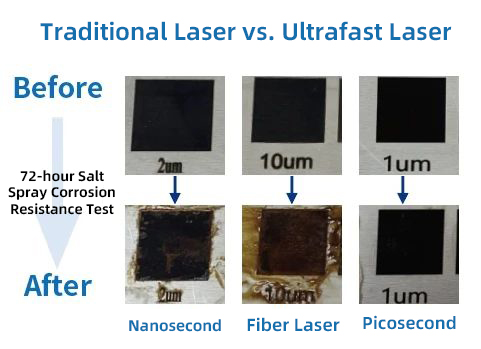

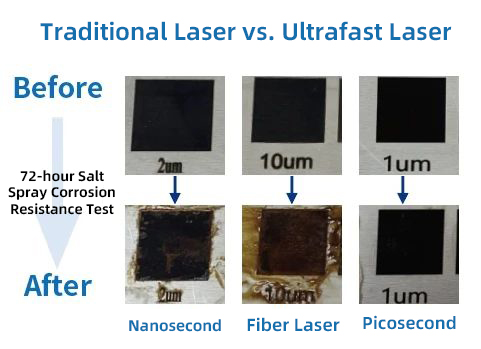

Salt Spray Corrosion Resistance Test

The AOC application team in the United States conducted salt spray testing in an environmental chamber to simulate harsh conditions of high pressure, high humidity, and salt fog. The results showed that, compared to traditional fiber laser and nanosecond laser marking, ultrafast laser marking exhibited superior corrosion resistance performance.

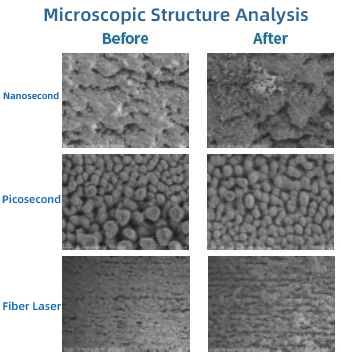

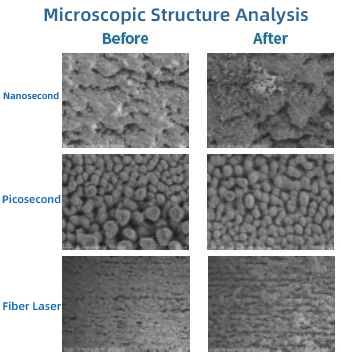

1、SEM Analysis of Laser Black Marking

To understand the superior performance of picosecond lasers in creating corrosion-resistant black markings on stainless steel, a detailed microscopic structural analysis was conducted using a scanning electron microscope (SEM). The markings before and after the salt spray test were analyzed.

SEM images reveal the following key aspects, highlighting the advantages of picosecond laser marking:

Minimal Heat-Affected Zone (HAZ)

SEM images show that, compared to other lasers, the heat-affected zone is significantly smaller, indicating minimal thermal stress around the marked area. This preservation of material surface structure helps maintain its corrosion resistance.

Enhanced Microscopic Structural Stability

The fine and precise energy transfer better preserves the microscopic structure of stainless steel, making its inherent corrosion resistance superior to that of nanosecond and fiber lasers.

Formation of Oxide Layer

The rapid energy transfer of the picosecond laser leads to the formation of a thin and uniform stable oxide layer on the surface, enhancing the corrosion resistance of stainless steel.

Pollution-Free Surface

The markings created by the picosecond laser show a clean, pollution-free surface. There is no presence of molten material or debris, ensuring a more stable and corrosion-resistant mark.

2、Passivation Test

The stainless steel ultrafast laser black marking from the AOC application team in the United States successfully passed the ASTM A967 standard passivation test.

Performance Analysis

1. Performance of Nanosecond and Fiber Lasers

Both the nanosecond ultraviolet and fiber laser systems left excellent black markings on stainless steel. However, the nanosecond ultraviolet system provided higher L.a.b values compared to the fiber laser while maintaining a good cycle time balance. A 72-hour salt spray test showed that the heat-affected zone generated by the nanosecond ultraviolet laser on the material's surface was smaller than that of the fiber laser, preserving the higher self-protective properties of stainless steel. According to the test results, the nanosecond ultraviolet laser is a viable choice for applications that require moderate durability and high contrast. Its performance makes it suitable for marking tasks such as general industrial marking and coding, where occasional color deviation is acceptable. This laser strikes a balance between cost and performance, offering an affordable solution for many marking applications. The fiber laser is best suited for applications with lower precision requirements and where slight color deviation is acceptable. It can be effectively used in cost-limited situations with less demanding marking environments. Although fiber lasers provide a cost-effective solution for less demanding applications, they may incur higher maintenance costs and more frequent rework requirements in environments that require high durability and minimal color deviation.

2. Performance of Ultrafast Lasers

Ultrafast lasers perform excellently in achieving durable black markings on 316 stainless steel. They exhibit minimal surface changes and maintain integrity even after exposure to harsh testing conditions. The picosecond infrared laser also produced markings with L.a.b values of 17, 0.7, and 1.63, indicating the deepest black marking and the most neutral color. This is because picosecond laser marking creates black effects by generating nanostructures that do not reflect light, and it leaves a sufficient chromium layer on the surface to maintain corrosion resistance, ensuring that the marking remains visible even after extensive and long-term corrosion testing. The markings form fine, periodic, and uniform ripple structures, presenting a matte black color due to the "light trap effect." This performance highlights the high quality and durability of ultrafast laser marking, making it an ideal choice for applications requiring precise and durable markings. Given its excellent performance and toughness, ultrafast lasers are well-suited for applications requiring high-quality, durable black markings. These include aerospace, medical devices, and high-precision manufacturing, where visual quality and durability are crucial. Although ultrafast lasers may involve higher initial costs, their efficiency in producing durable and high-quality marks, coupled with reduced rework and maintenance requirements, can lead to lower long-term operational costs.

INNO Laser AMT Picosecond Series

1. AMT Picosecond Laser

INNO Laser's third-generation ultrafast lasers currently include picosecond lasers with wavelengths ranging from ultraviolet to green light, and femtosecond lasers ranging from ultraviolet to infrared. This model features leading frequency doubling crystal optimization technology, fully automatic crystal wavelength-switching technology, and spot compensation technology. These advanced technologies ensure excellent beam quality, extend crystal lifespan, and enhance the stability of the laser.

The series of lasers offers excellent beam quality (M² < 1.1), astigmatism and symmetry < 10%, reliable pulse and power stability, and customizable spot roundness of over 95%.

2. Picosecond Marking Applications

As demonstrated by the experiments mentioned above, using picosecond pulsed lasers for black laser marking on stainless steel provides better corrosion resistance, and this marking can maintain clarity over a long period in high-demand environments. It is more suitable for the following scenarios:

Medical Field

Medical: Permanent and readable markings on surgical instruments, implants, and medical tools for identification, tracking, and regulatory compliance. These markings must withstand repeated sterilization processes.

Consumer Electronics

Marking electronic components, printed circuit boards, and casings for identification, tracking, and anti-counterfeiting measures. The markings must resist environmental factors, such as humidity and chemicals.

Automotive Manufacturing

Marking parts and components for identification, tracking, and quality control. This includes engine parts, fasteners, and safety-related components.

Aerospace

Marking aircraft parts for identification, tracking, and maintenance records. The markings must withstand harsh environmental conditions, including temperature variations and exposure to corrosive substances.

**INNO Laser is a highly trusted and closely partnered laser supplier for ARGUS laser marking equipment.