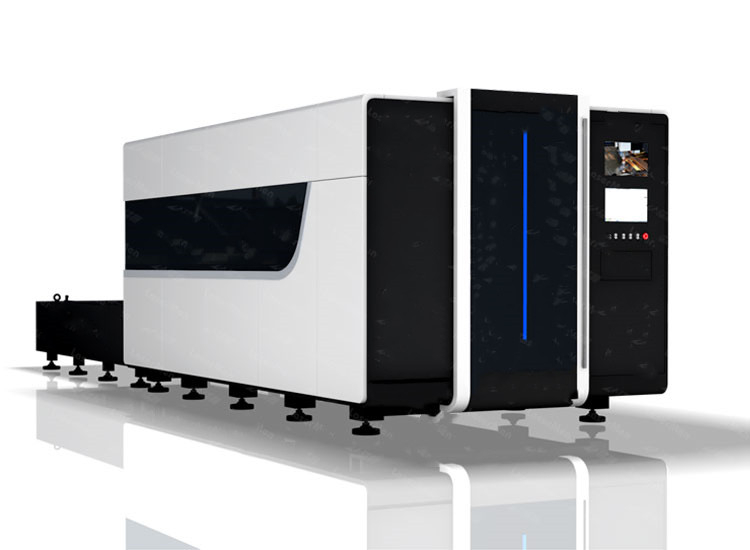

CNC LASER ENGRAVER AND CUTTING MACHINE

1) Simple structure in linear type, easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automation and intellectualize, no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

| | Technical Parameter |

| | |

| | |

| | |

| | |

Origin Setting(Red Pointer) | |

| | |

| | Aluminum Strip or Honeycombe Worktable |

| | |

| | |

| |

| | |

| |

| |

| |

| |

| |

| | |

| | |

Whole Stepping Angle:1.2° |

| |

| | |

| | CorelDraw, Photoshop, AutoCAD, etc |

| | AI, PLT, BMP, DXF, DST, T100, etc |

| | |

| | |

| | |

Repeated Positioning Accuracy | |

| | |

| | 0-15mm(it’s up to the material) |

| | Circulation Water Cooling |

| | |

| | 220V/50Hz/60Hz/2kVA, 110V/50Hz/60Hz/2kVA |

| | |

| | |

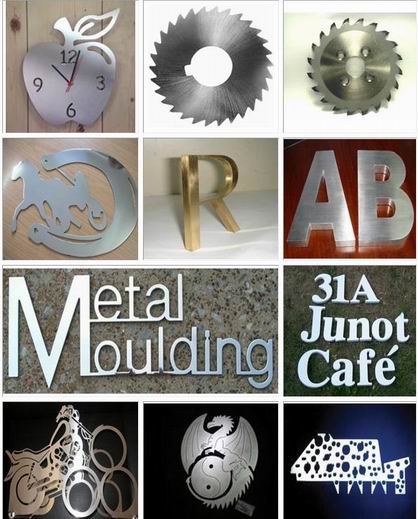

Applicable Fields

This machine is widely applied in the field of advertising industry, decoration, furniture, model manufacturing, and handcraft industry for the fine engraving, cutting and hollowing out on almost all non- metallic materials with all kinds of characters, graphs, images, trademarks and so on.

Applicable Material

Acrylic, Plastic, Plank, ABS, Wood, Plywood, Bamboo, Paper, Organic glass, MDF, PVC, Rubber, Density board, Cloth, Leather, Derma, Corfam, Textile, Chemical leather, etc.

Machine Application