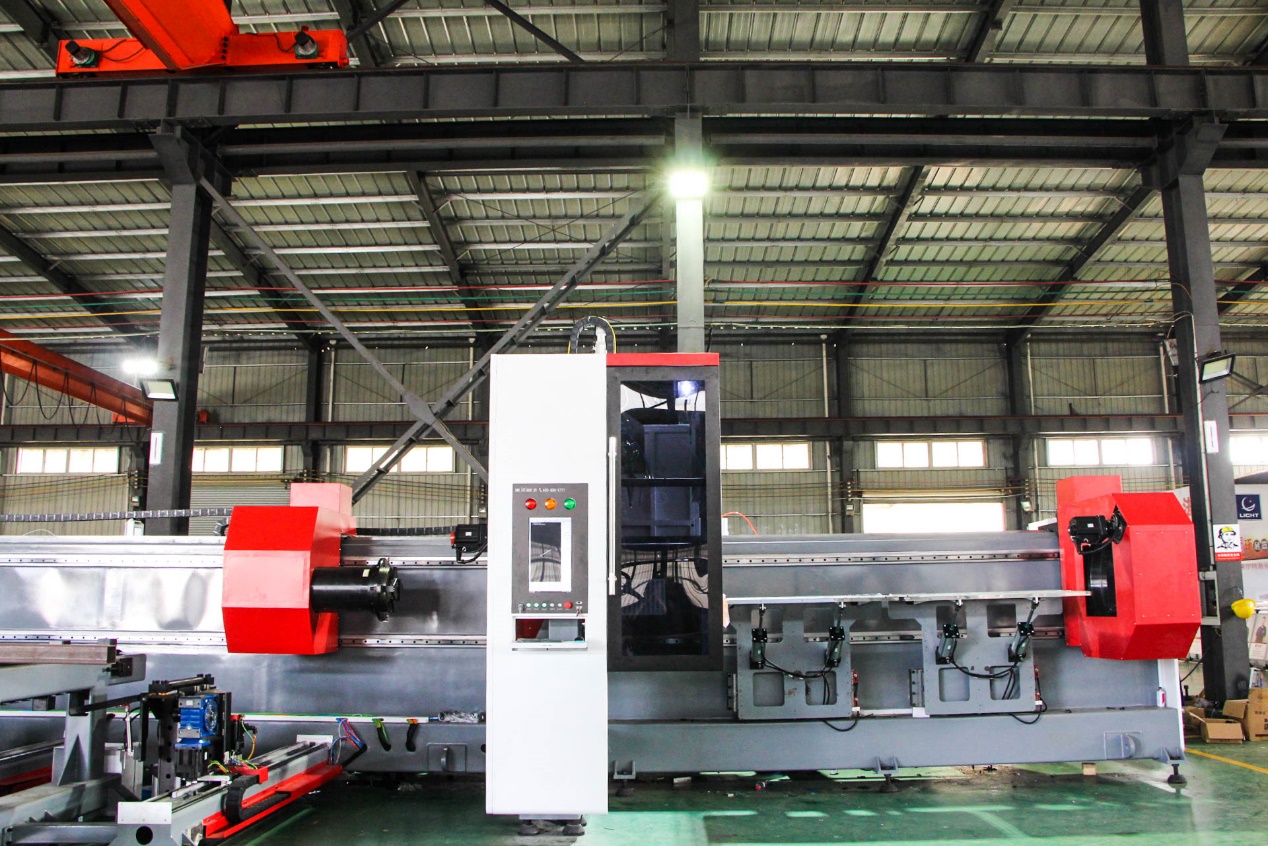

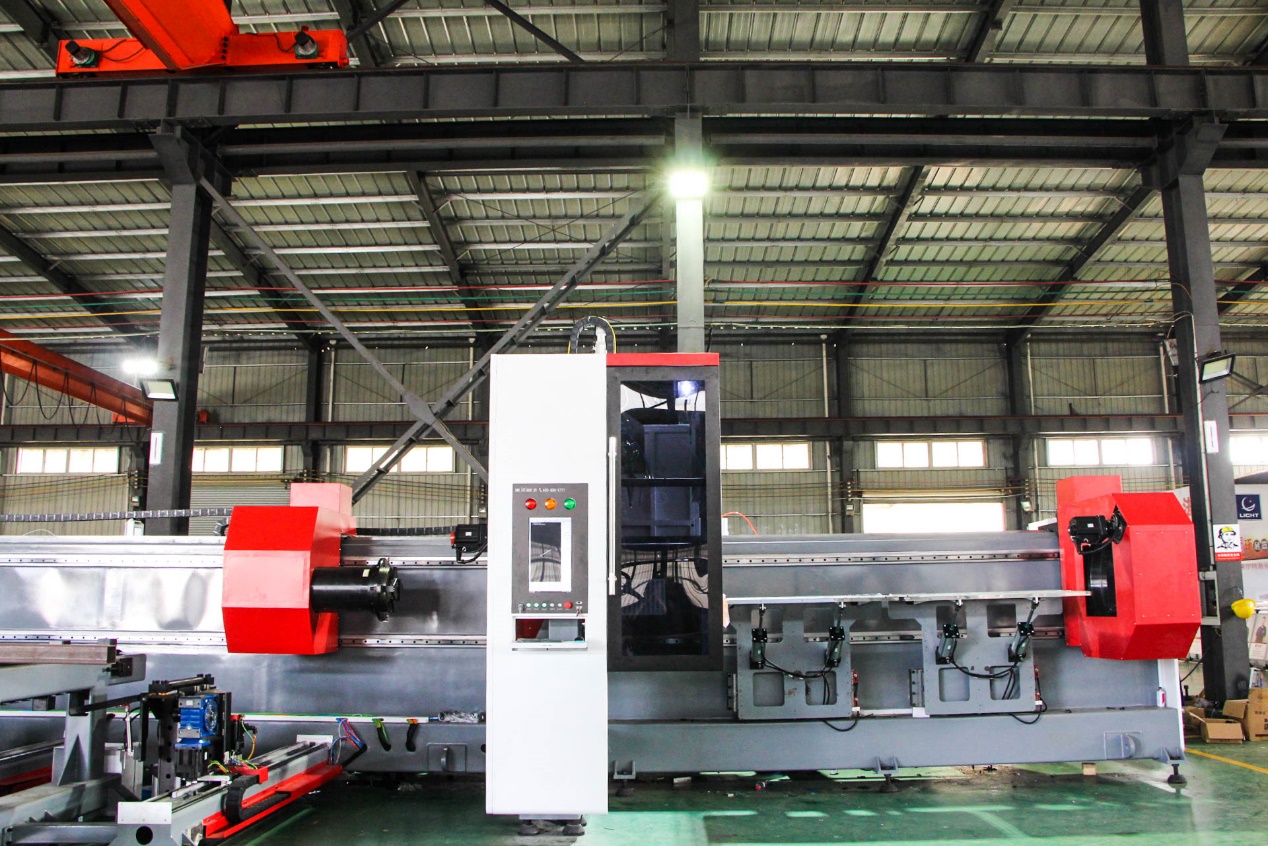

Product Paramenters

Laser Pipe Cutting Machine Parmeters |

Laser Power | 1500W/3000W/6000W |

Wavelength | 1080±3nm |

Laser method | Fiber Laser |

Power adjustable range | 10-100% |

Average power output | 80% |

Cutting speed | 0-100m/min. |

Long-term working stability | ±2.5% |

Modulation frequency | 20KHz |

Fiber length | 15m |

Machine power consumption | ≤12KW |

Working voltage | 380V /50-60Hz /4.5Kw (Customized) |

Cooling system | Water cooling |

Working temperature | 10-40℃ |

Storage temperature | -20-50℃ |

Humidity | 0-90℃ |

Weight | 5300 kg |

Appearance size | 6000/9000/12000*2400*2500mm |

Technical Parameter

Laser source

MAX/RAYCUS/RECI fiber laser source High electro-optical conversion efficiency (>40%), good beam quality, high energy density,

wide modulation range, high frequency, high reliability, long life, maintenance-free operation and other advantages

Cutting head

The BLT4 series is a high-performance and cost-effective intelligent cutting head developed for various processing equipment such as flat surfaces, bevels, and pipes

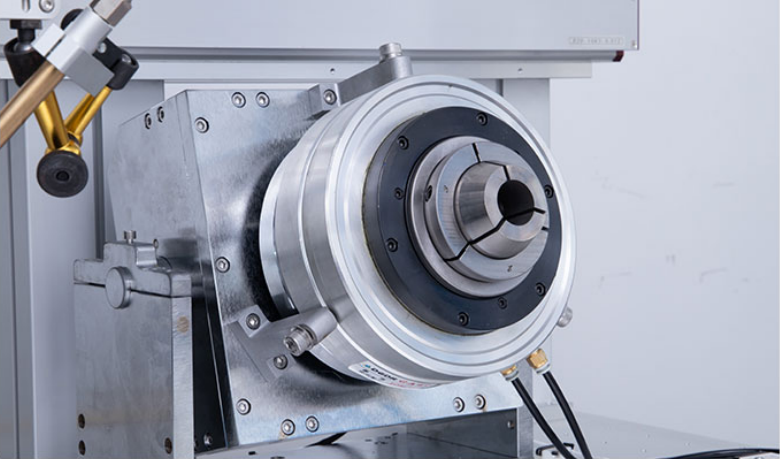

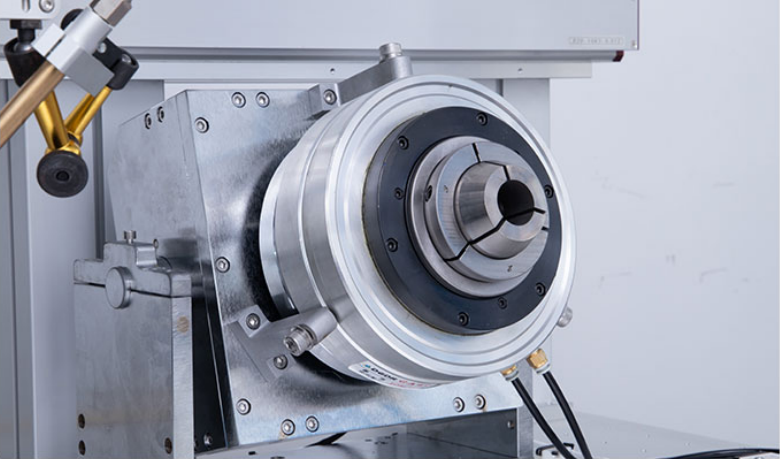

Rotary Device

Two rotating devices work at the same time to maintain high efficiency welding.

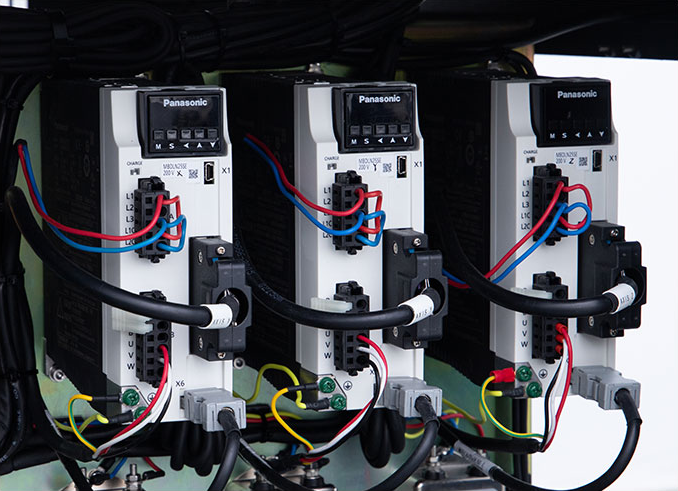

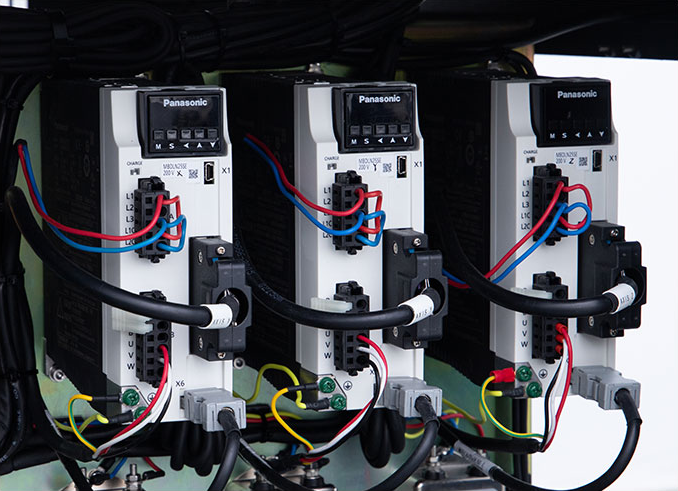

Panasonic servo motor

High quality Panasonic servo motor and power accessories, ensure the machine

work safe and stable.

Power Supply

Cannywell power accessories, ensure the machine work safe and stable

Products Description

What is fiber laser cutting machine application ?

Fiber laser cutting machine is a new technology special for cutting most of metal , Material Application:Stainless steel, carbon steel, alloy steel, silicon steel, aluminum,aluminum alloy, galvanized sheet, pickled sheet, copper, silver, gold, titanium and other metal sheet marking and engraving. Compare with traditional cutting , it has many advantage as follow:

1.Easy to operate , no need any experience, even a women also can did well on it .

2. High efficiency , 2-4 times faster than traditional cutting.

3. Cost is much lower, labor cost and electricity cost are reduced by at least 50%.

4. Employee safety. No radiation, no harm to people, just wear glasses.

Customer Photos

Recommend Products

Company Profile

ABOUT SUNIC GROUP

Wuhan Sunic Group is a professional laser machines and solar panel products lines equipments manufacturer since 1998. We are specialized in Design, R&D, Manufacture, Sales and Service for laser machines.

We supply customized solution for different materials processing , such as Invitation cards, Wedding cards, Pop up cards, Pop up books , Candy box , Paper products, Acrylic , PMMA, LGP, Jeans Wash, Leather, Fabric, Textiles, Wood, MDF, Laminate materials ,Marble, Package Film, Metal / Plastic products, etc.

Our laser equipment is widely used in Solar Photovoltaic production line, IC Component Production, Leather&Garment Industry, Advertising Signs, Decoration crafts, Equipment spare parts, Daily hardware, Measurement tools, Medical instruments, Printing&packing industries, etc. Sunic Group would like to be customer's technical laser and solar equipment consultation and support for further development and progress together.

FAQ

What kind of laser machine and model should I choose?

You can tell us your processing material, working size and detail requirement, detail work by picture or video so that we can judge whether our machine can meet your need

What kind of materials does the laser machine can process?

We have different laser machines, such as Fiber laser, CO2 Laser, UV Laser Green Laser. Normally Fiber laser can process metal and plastic. CO2 laser is for processing non metallic materials, such as Acrylic, PMMA,Wood, Glass, Leather,Jeans, Paper, Textiles Garments and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass, crystal and some special processing job.

Is it easy to operate?

We will send you manual and guide video in English, I can teach you how to operate the machine. lf you still can not learn how to use it, we can help you by Team viewer online help software.Or we can talk by phone email or other contact ways.

What s your guarantee. in case the machine breaks down?

The machine has one year guarantee. If it breaks down, generally speaking our technician will figure out what the problem may be, according to client's feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

How will you do the after- sale service?

We will firstly check your problems online through Team viewer,E-mail, Whatsapp or other contact way, if it is easy to handle it, we will guide you online to fix it or send you the spare parts for replacement.

What is your equipment lead time?

Fiber laser marking machine lead time is around 7 working days. CO2 laser engraving&cutting machine lead time is around 2-3 weeks 3D dynamic CO2 laser marking machine lead time is around 10 working days.

How will you do the package and shipping?

All of our equipment are packed in export standard cases. Express, air shipping, sea shipping are all available.