Technical Parameter

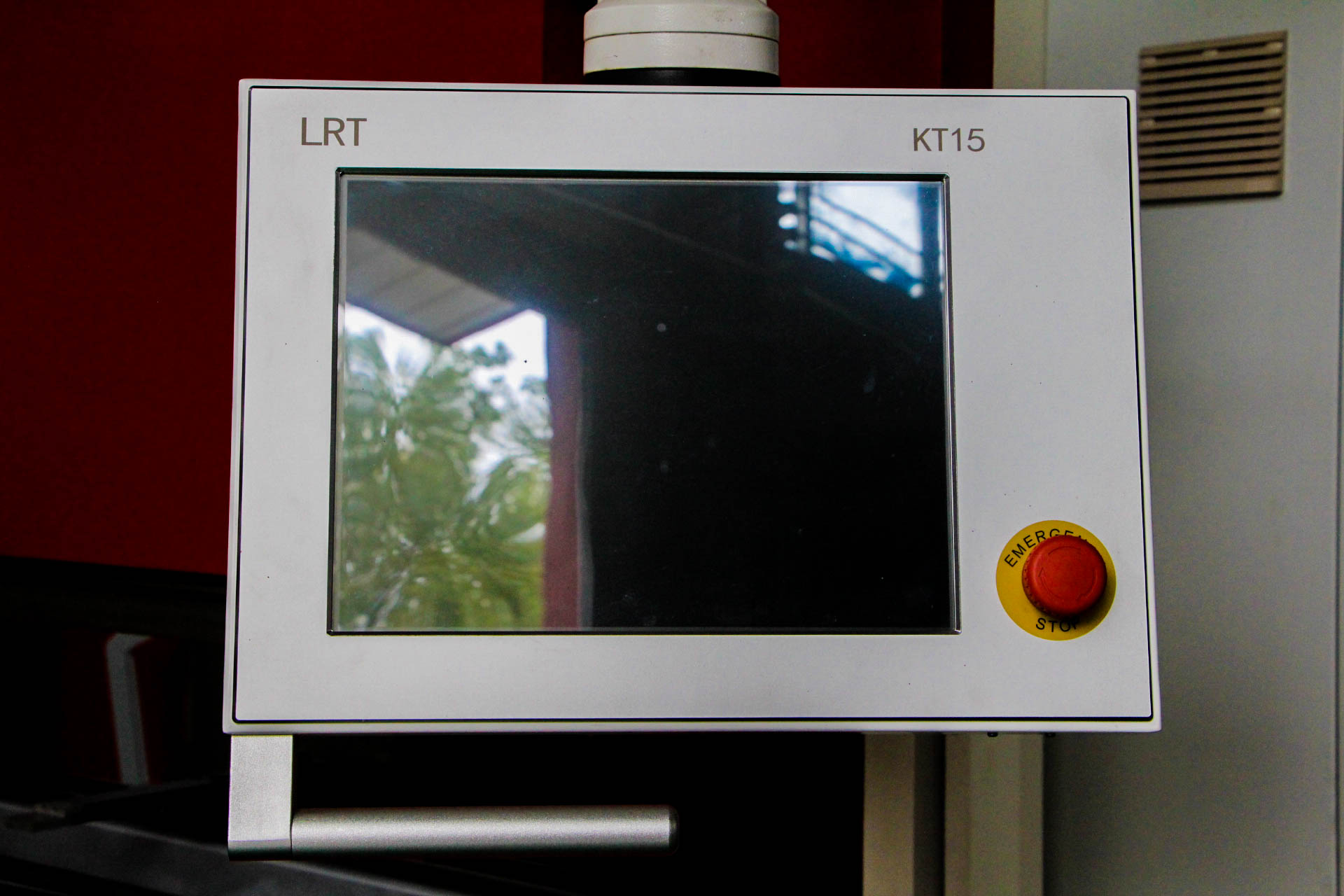

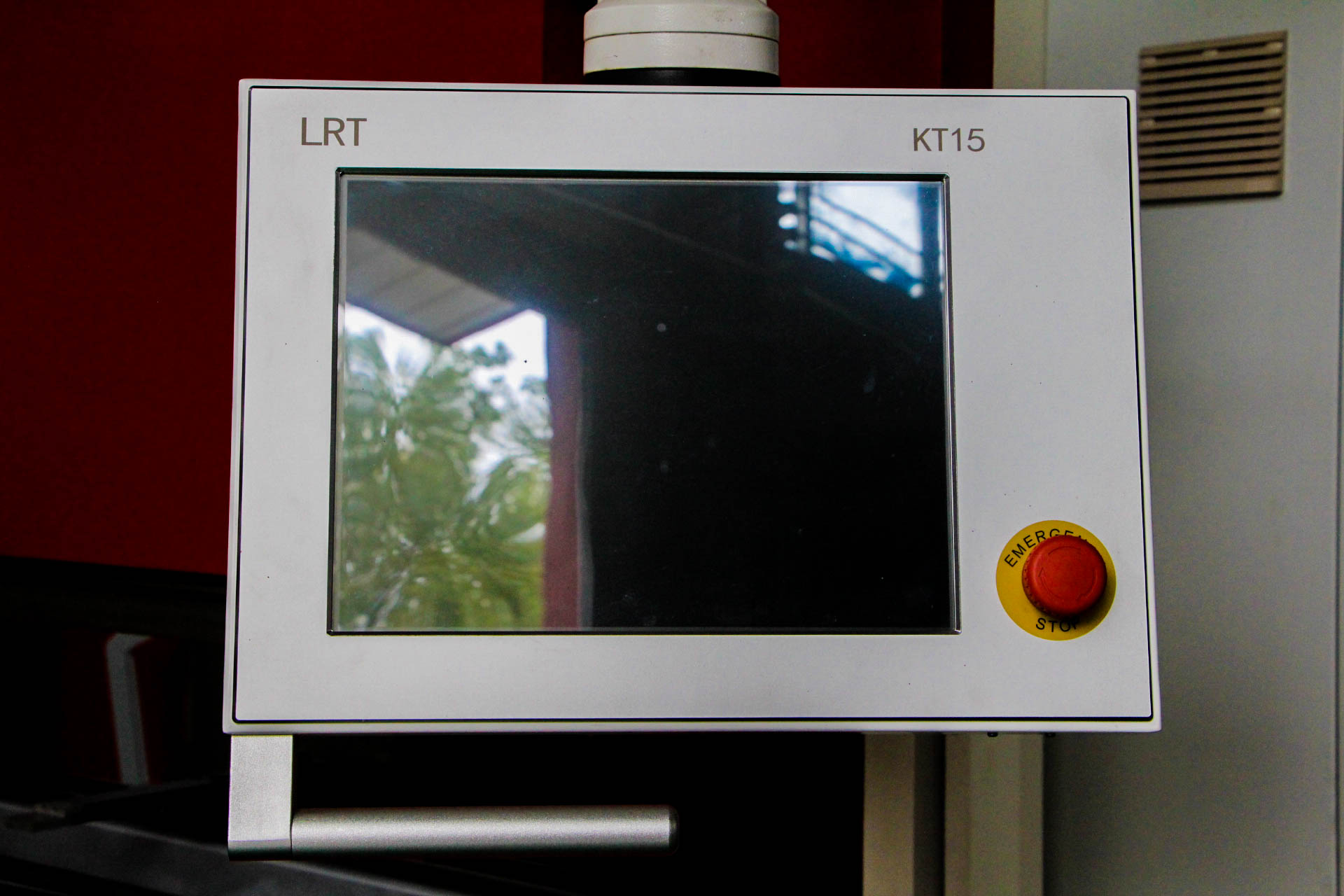

CNC SYSTEM We provide controllers from three reputable brands: Delem, Cybelec and KT.The efficient algorithm optimizes the bending cycle, reduces the setup time for work steps, and enhances the overall efficiency of the bending process, particularlyin batch processing scenarios. |

|  |  |

|

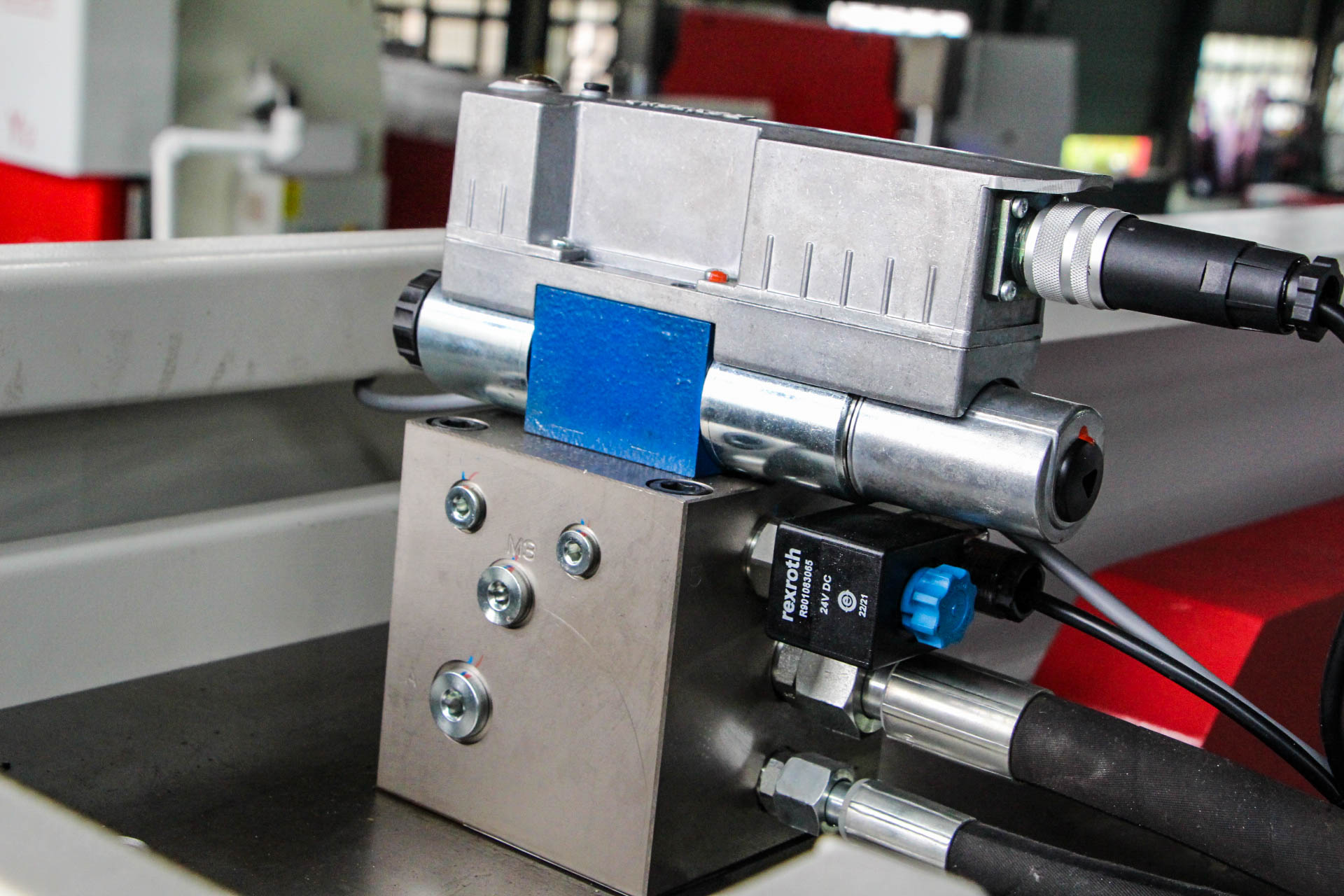

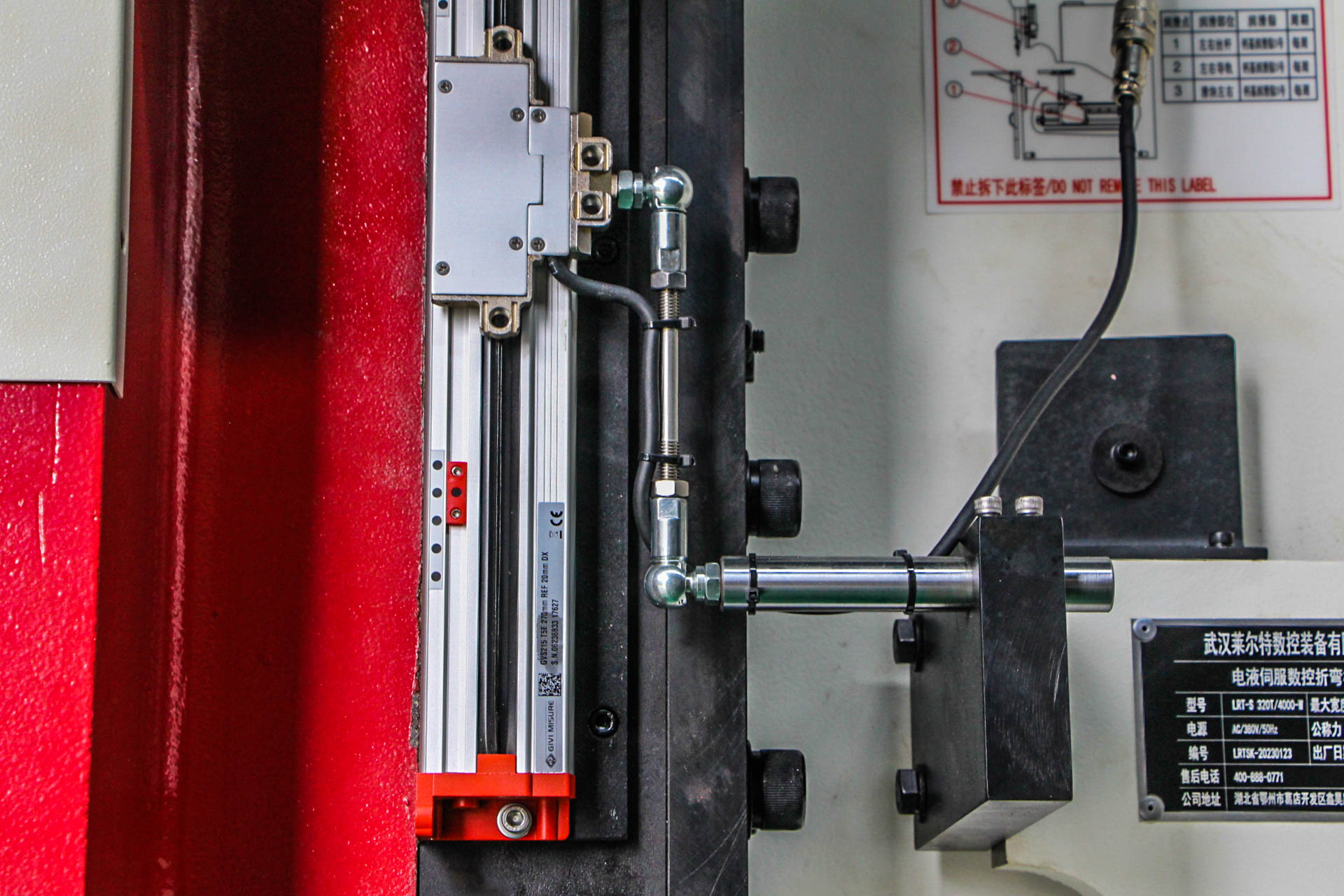

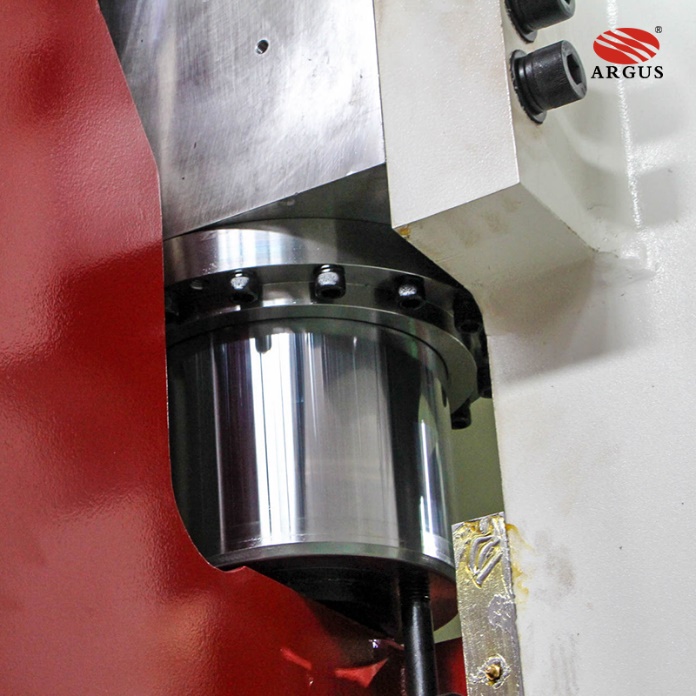

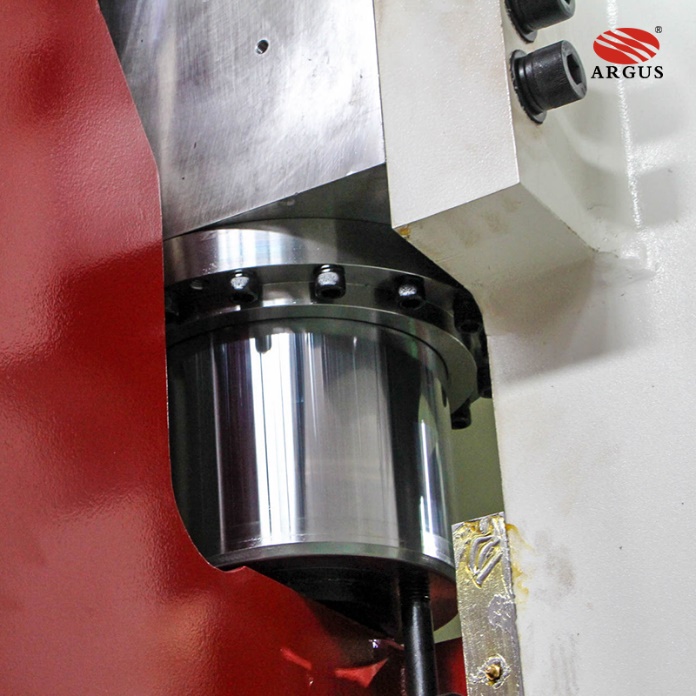

Hydraulic Syste

We has the renowned German brand Rexroth for our hydraulic system, which is distinguished by its high efficiency and low failure rate. It boasts robust anti-eccentric load capabilities, high accuracy synchronization, and an impressive power density ratio. |

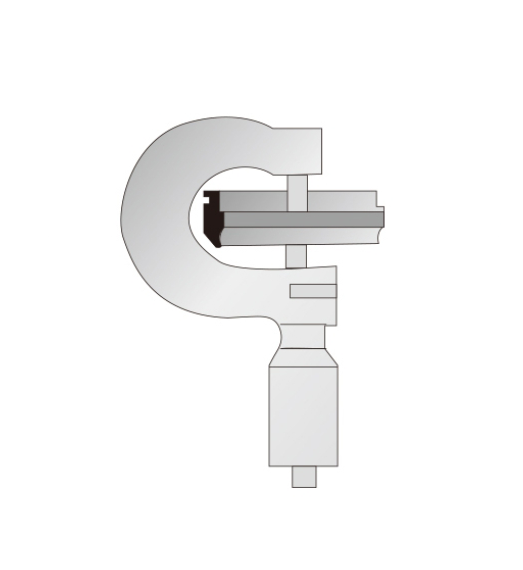

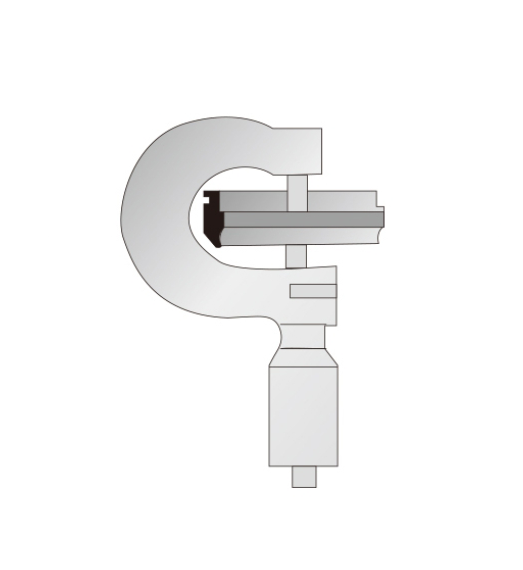

Crowning

Our independently designed system calculates the compensation value based on the overall deformation of both the ram and worktable. This enables the deformation curve of the bed to align seamlessly with the compensation curve, ensuring optimal straightness and angle consistency in our products. |

|

|

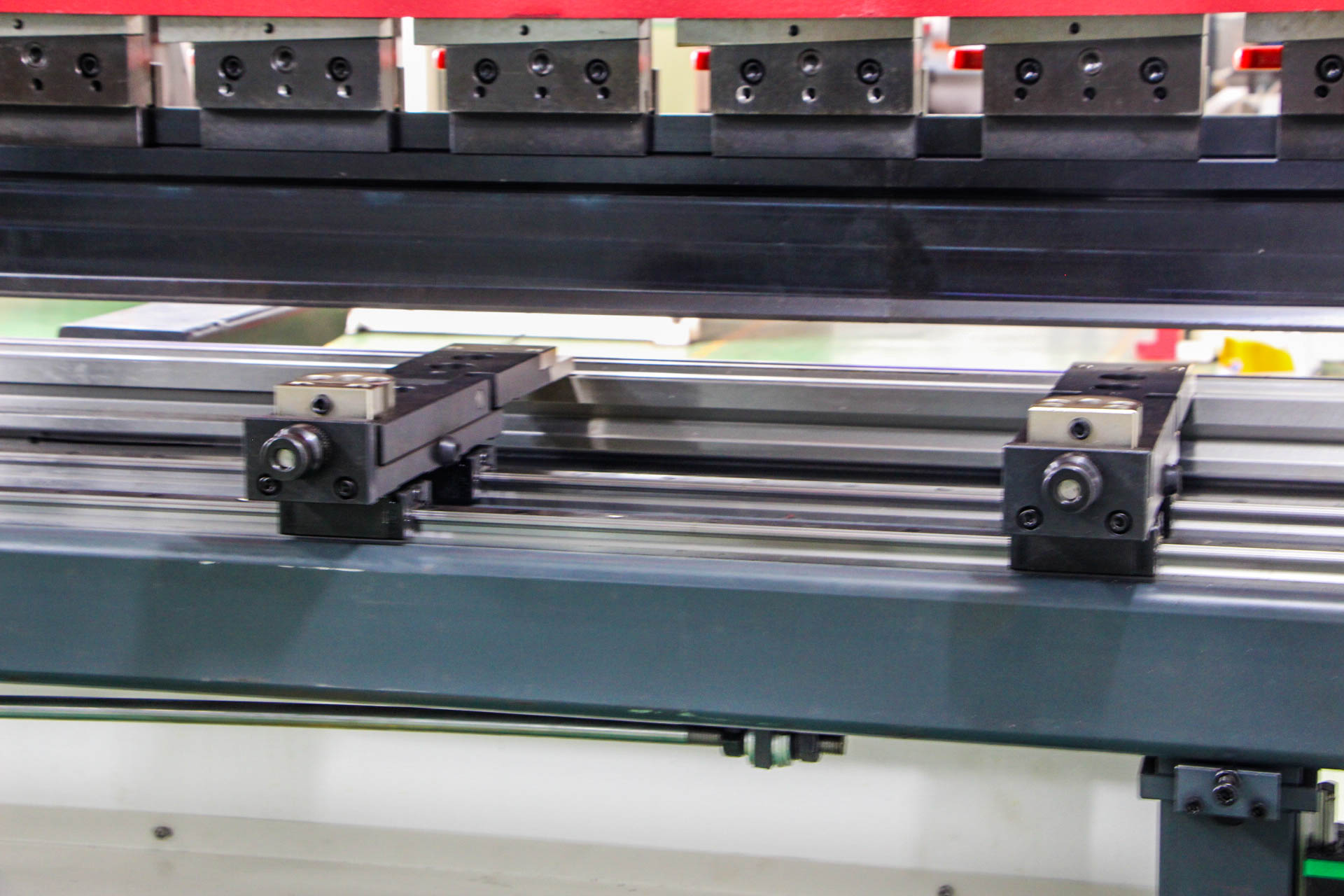

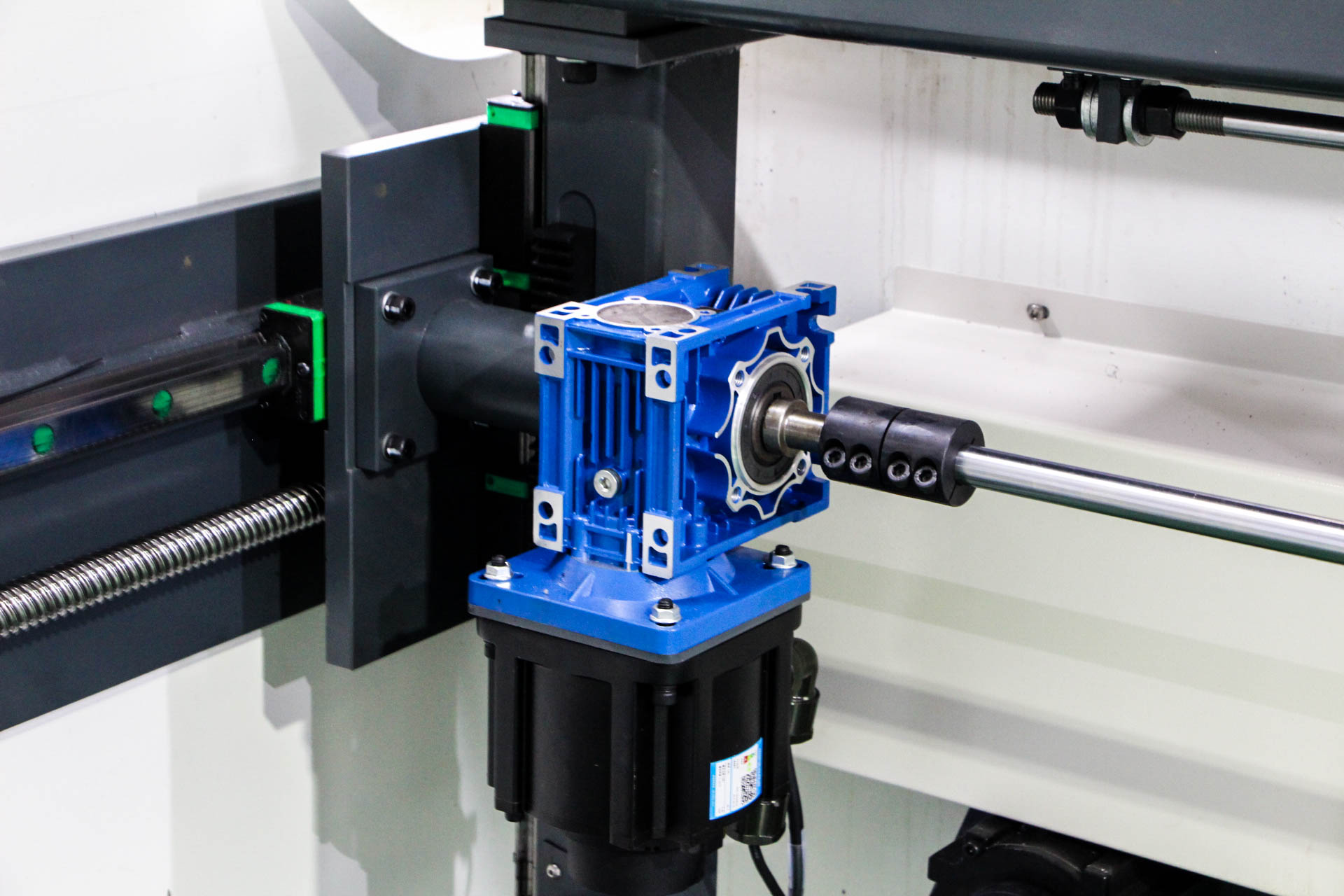

Mechanical compensatio

Disturbance compensation workbench Compensation for bending materials with the same plate thickness in one go is different from hydraulic compensation, which constantly shuttles back and forthThe structure of motion and mechanical compensation greatly reduce fatigue deformation of the machine tool workbench and improve its service life |

Laser safety Argus curtain

Italian PSD laser safety protection device comprehensively protects the personal safety of bending machine operators, avoiding the danger caused by rapid sliding on the machine tool. Once any obstruction enters the Italian PSD protection area, the Italian PSD will immediately send a signal and interrupt the downward movement of the slider. |

|

product Description

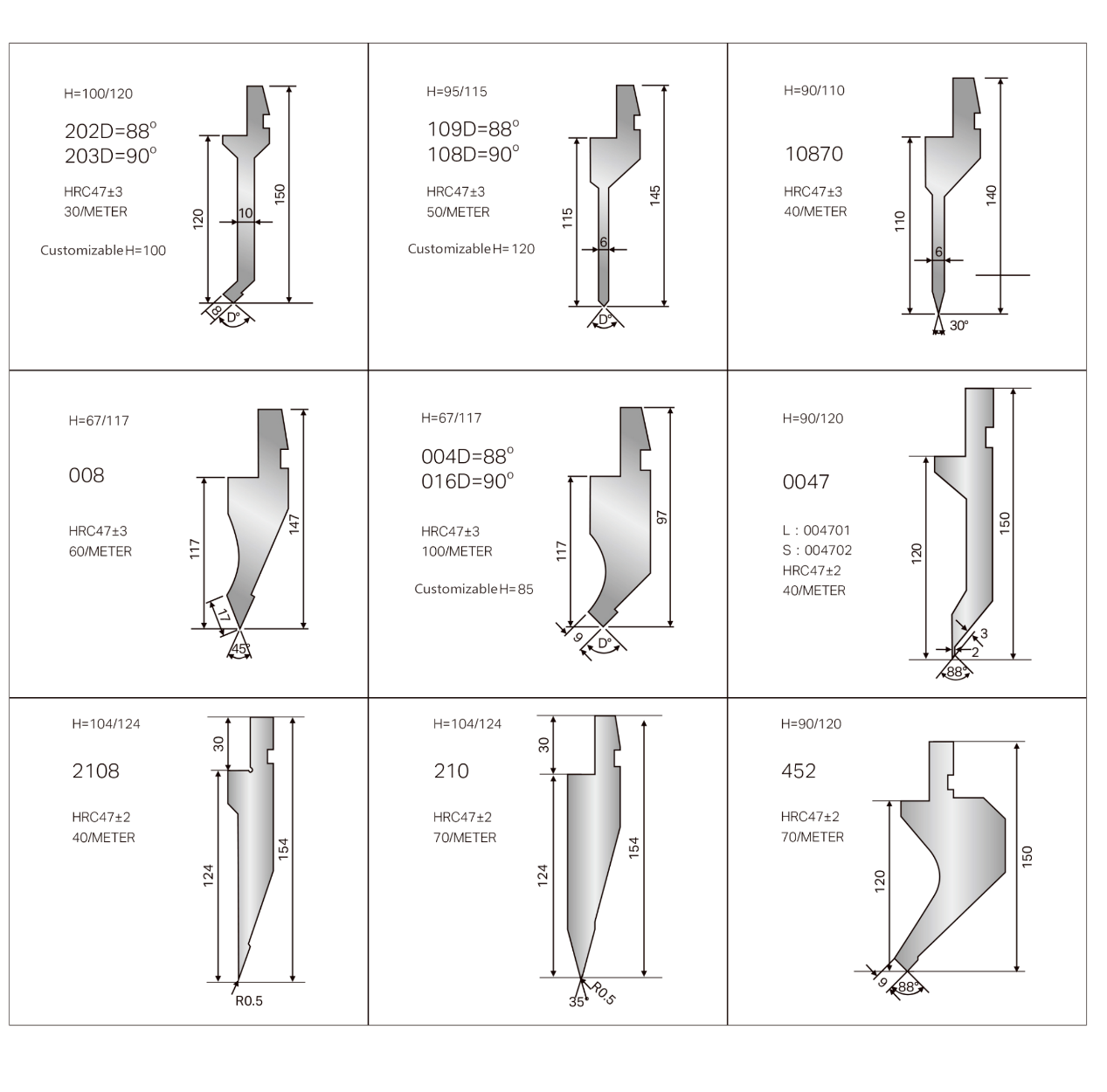

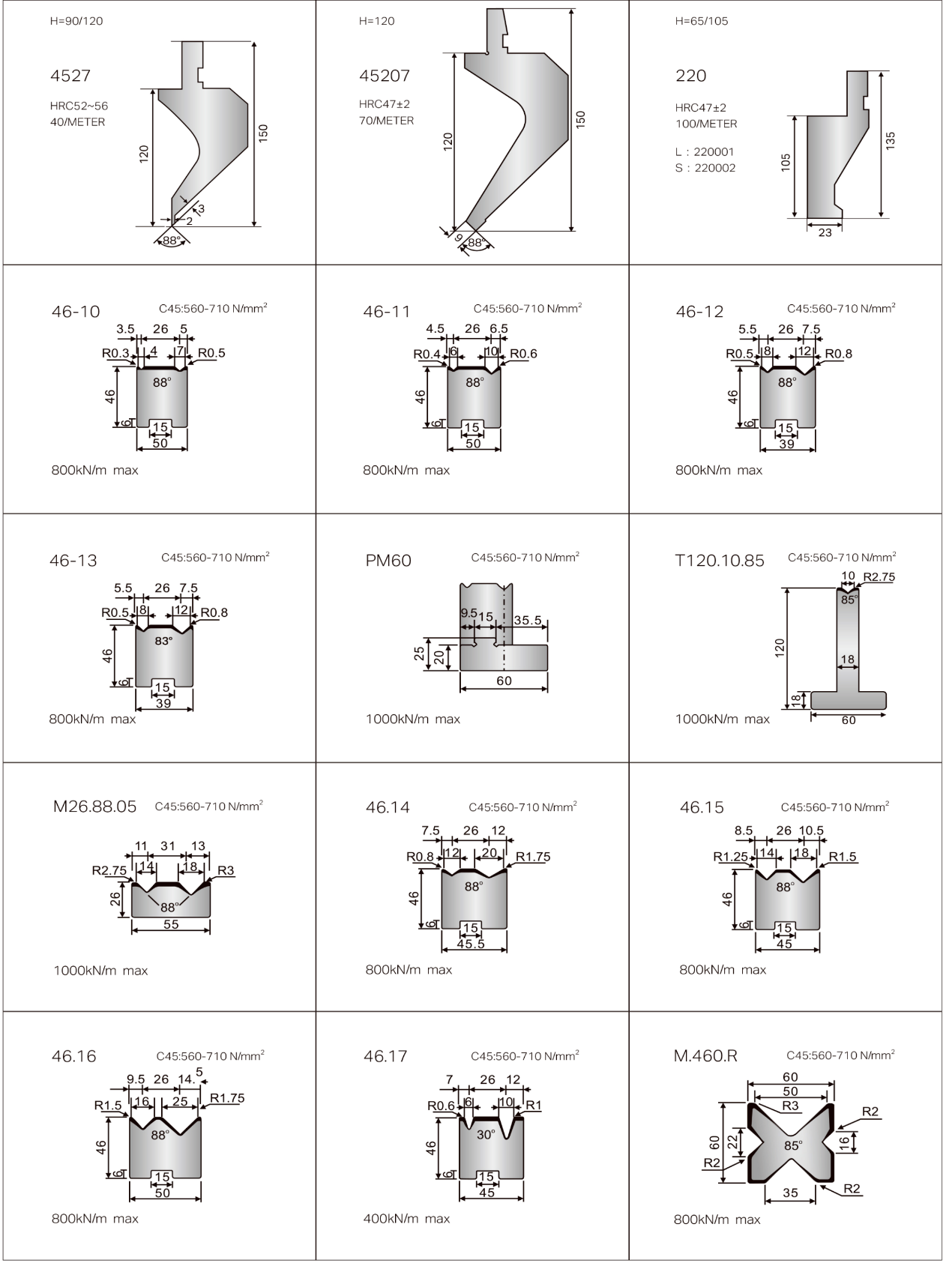

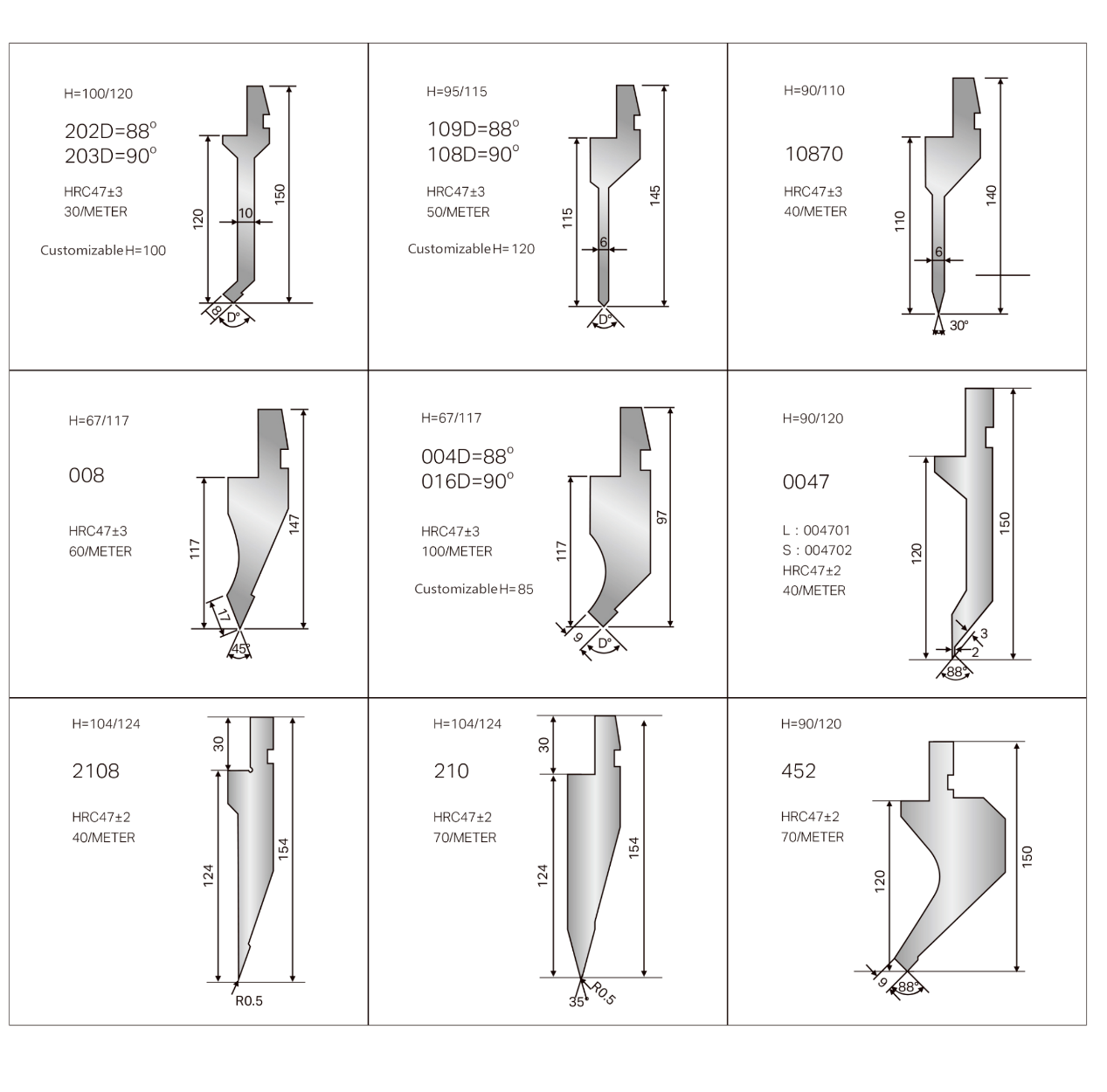

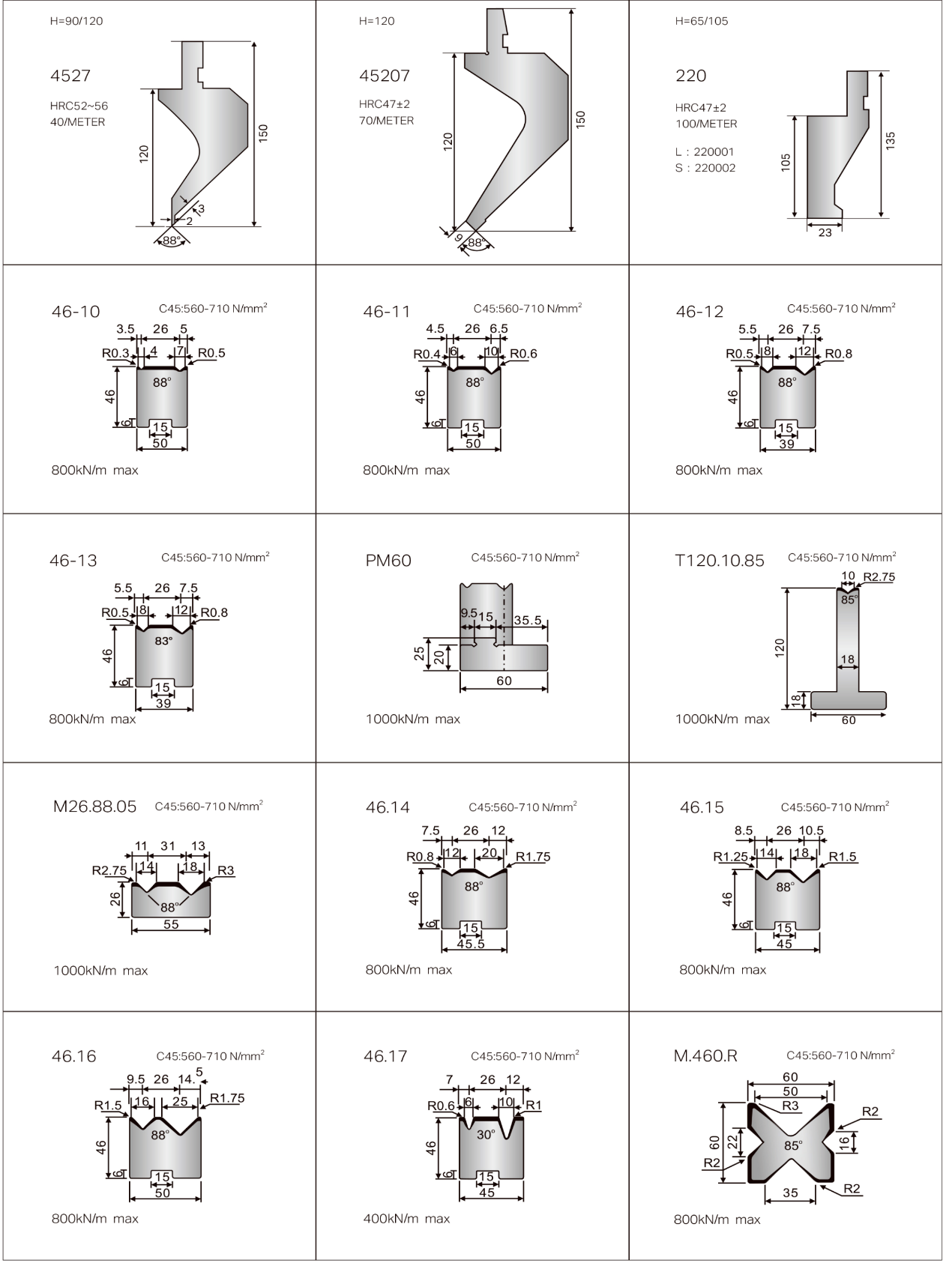

High precision

The molds for Argus' bending machines are all quenched and ground and the dimensional tolerance of all the key machined positions has reached a very high precision level, which can provide you with the best bending performance. A second treatment arising from correcting errors can be avoided if you choose the Argus molds for Ragos' high precision bending machines, thus reducing the manufacturing cost. In addition, Argus' bending machine molds that have been subjected to heat treatment have a longer life than ordinary molds. |

|

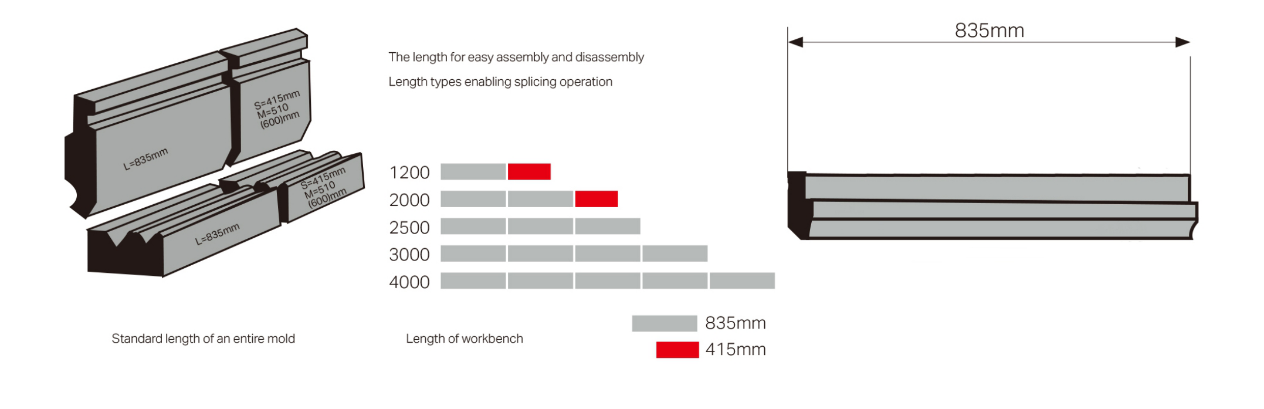

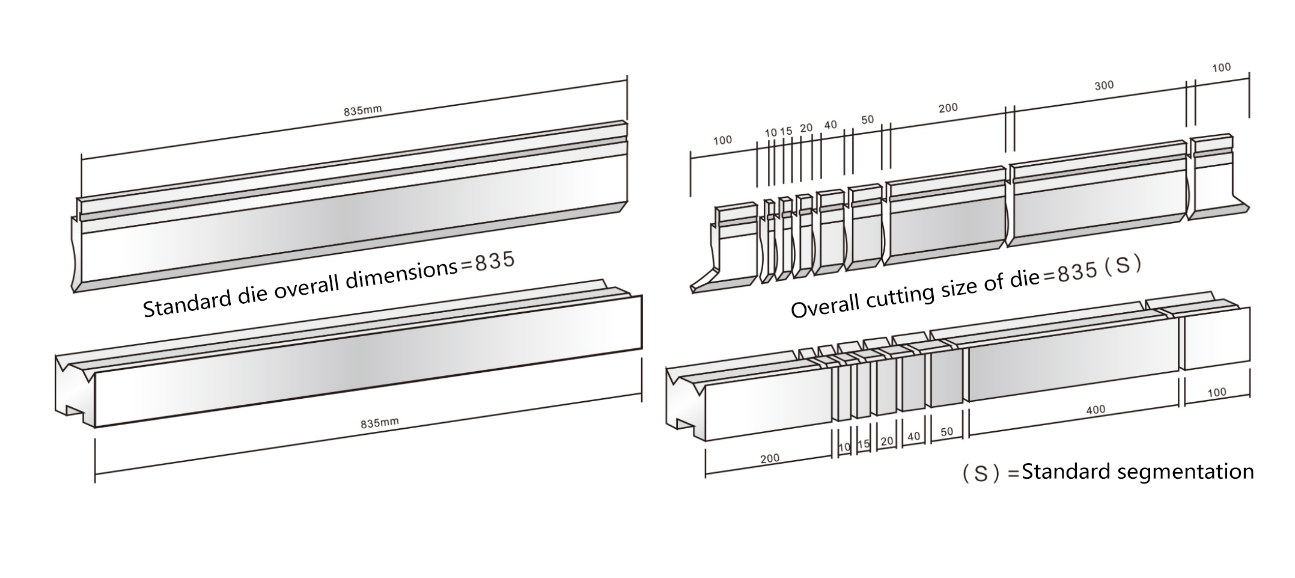

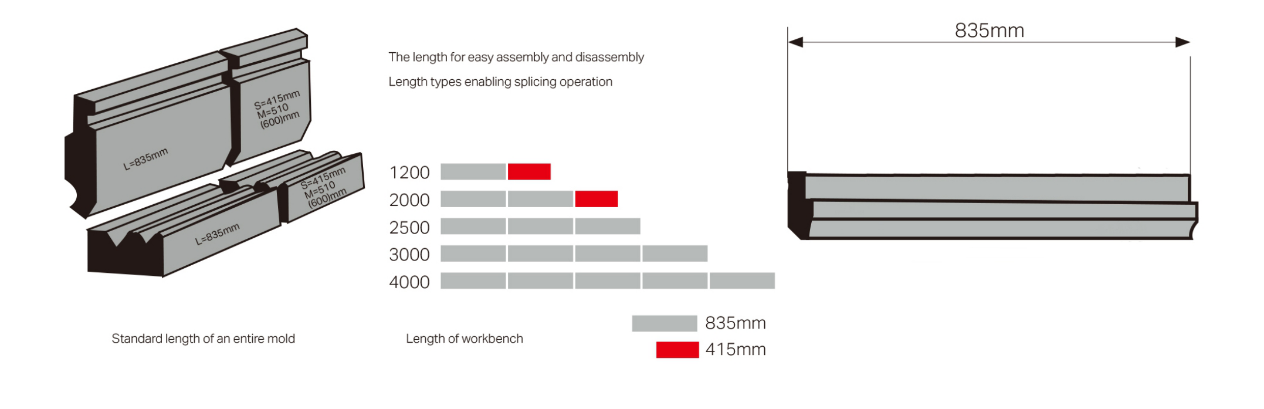

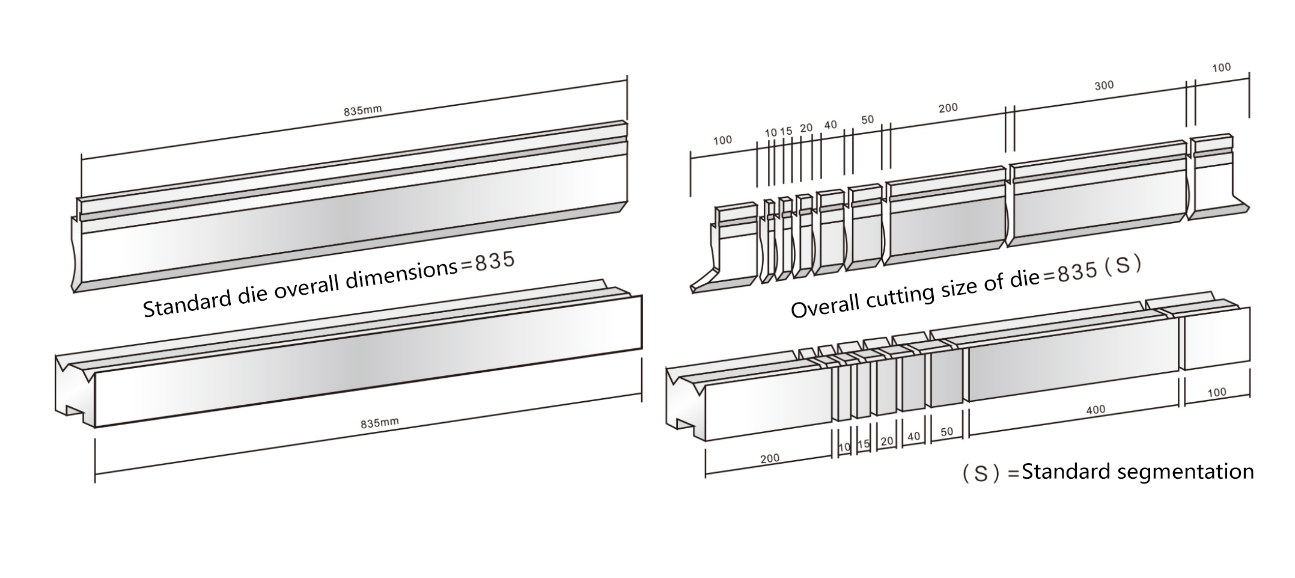

Standardization

The molds for Argus' bending machines are designed as standard-length specification, which makes it possible for simple assembly.

|

|

Shape of bending tool mold Dimension of tool mold combination 2000mm=(835x1+415x1+835(S)x1) 3200mm=(835x3+835(S)x1) 4000mm=(835x4+835(S)x1) |

|

|

To facilitate the bending operation of material of any length, the standard split molds fall into two specifications: mold section A and B: Section A: Upper mold: 100 (left lug), 10, 15, 20, 40, 50, 200, 300, 100 (right lug) = 835mm (1 lot)

Lower mold: 10, 15, 20, 40, 50, 100, 200, 400=835 mm (1 lot)

|  |

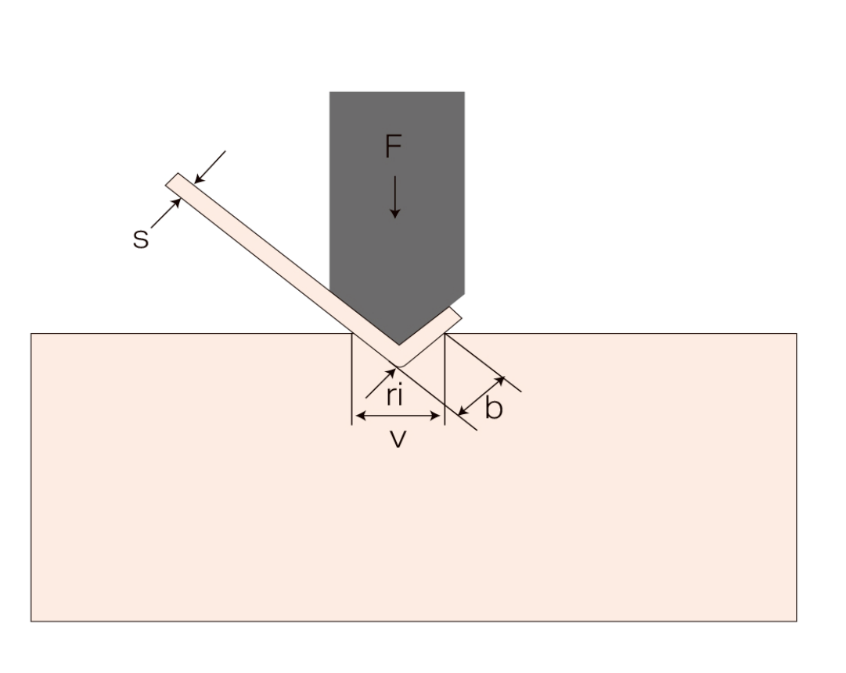

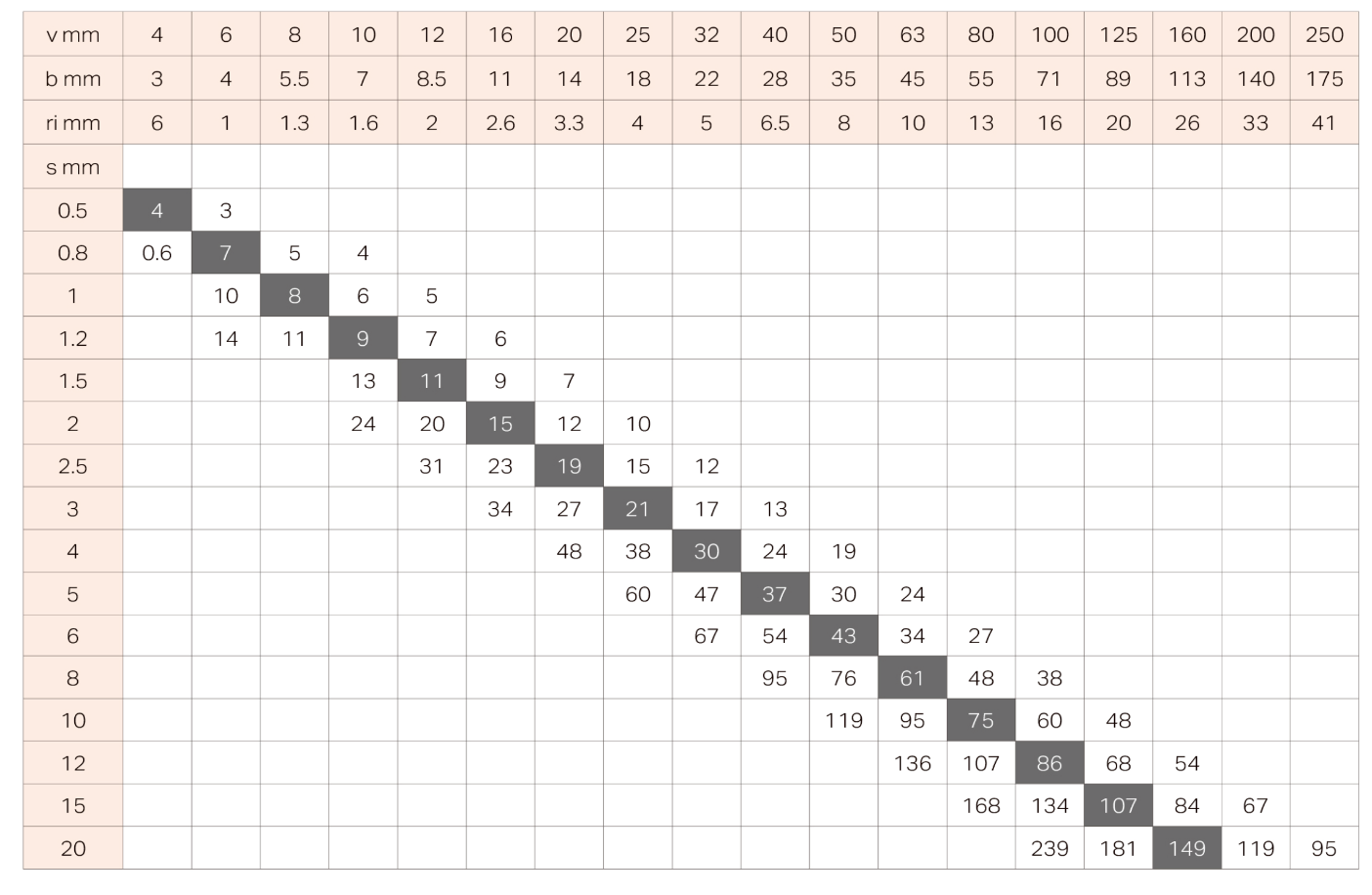

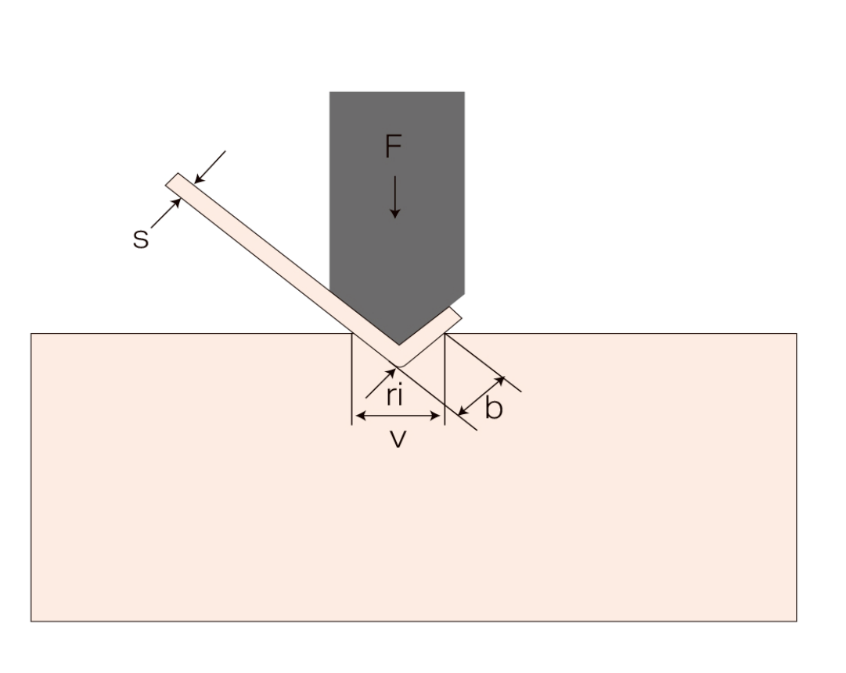

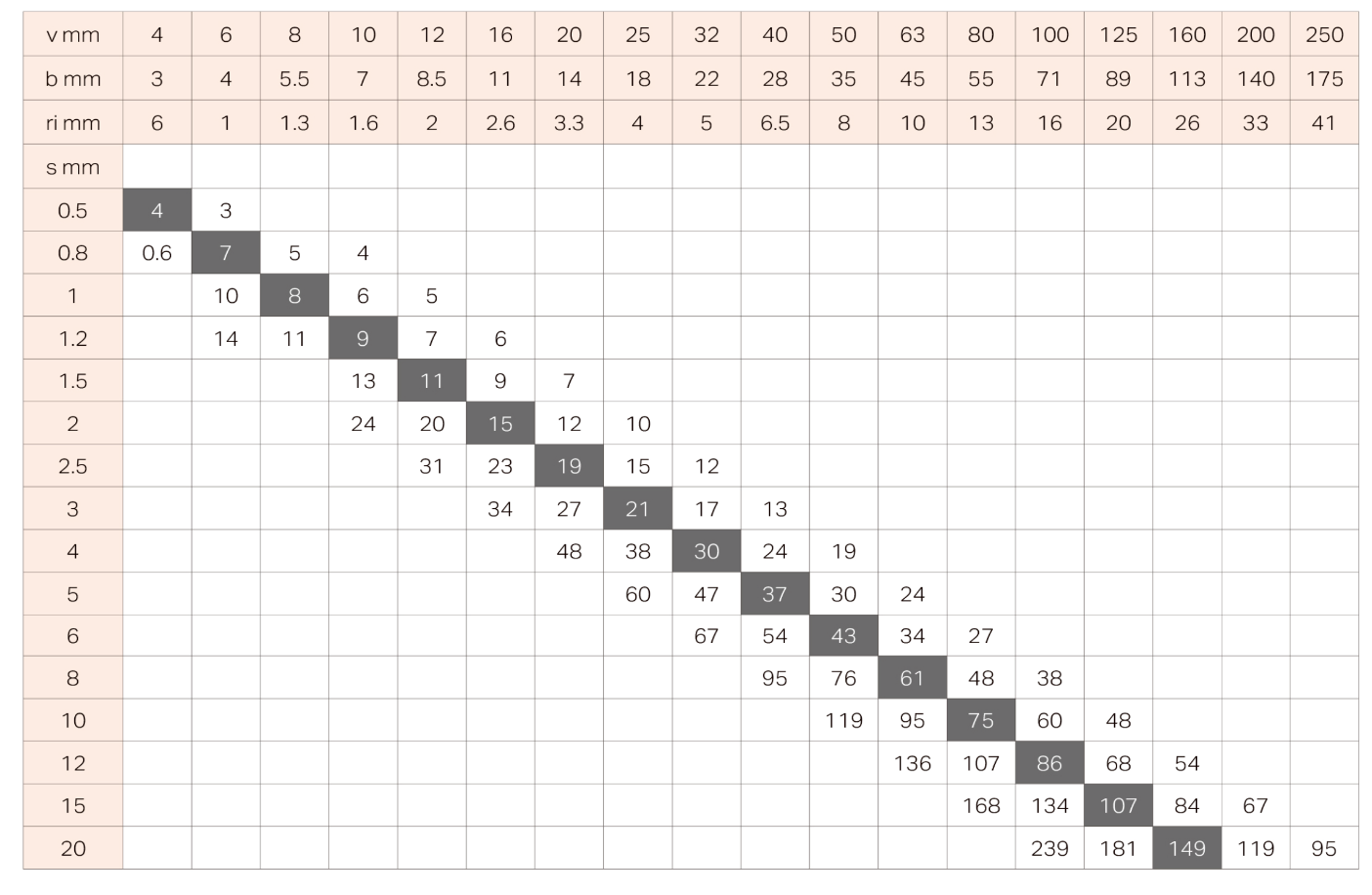

jixiF=Manufacturing pressure (tons/m) ri=Inner radius b=Minimum foot length of plate (mm) s=Plate thickness (mm) v=V-groove size of bottom mold (mm) |

|

|

|

= Data corresponding to V-groove dimension and material tensile strength Manufacturing pressure (tons/m) obtained through the calculation based on 42 kilograms per square centimeters (kg/mm?) |

|

|

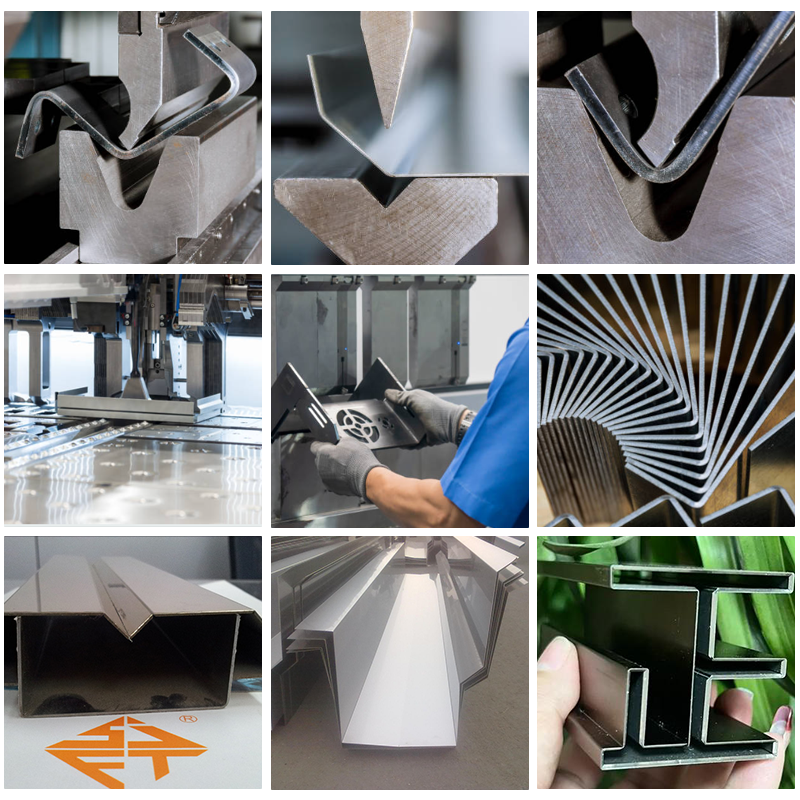

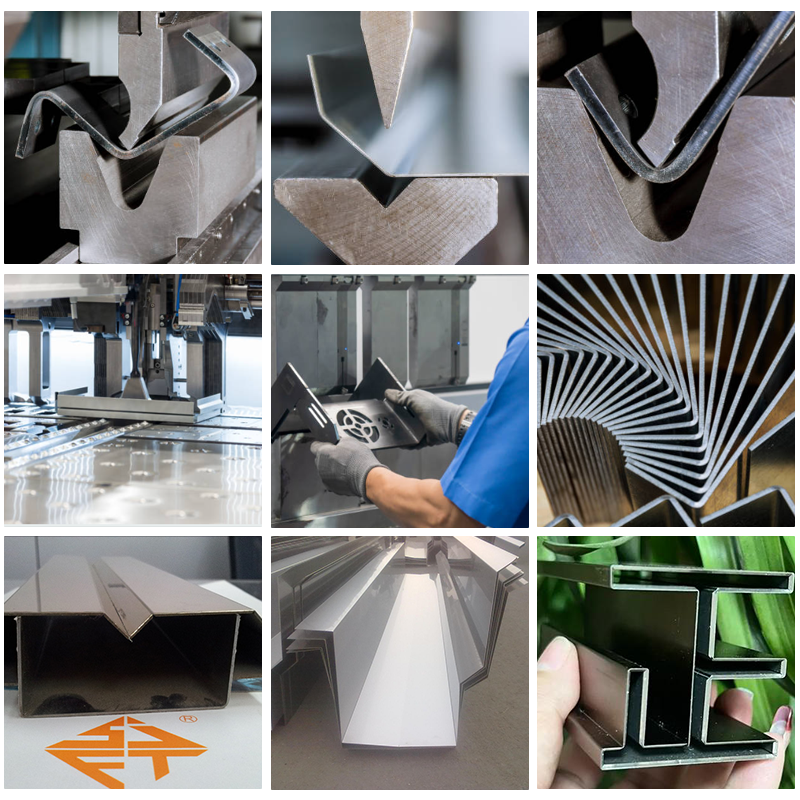

Press Brake Samples

Customer's Cases

FAQ

What kind of Press Brake and model should I choose?

Please tell us your processing material, sheet size, bending angles, and any specific requirements, along with pictures or videos if possible. This will help us determine if our machine can meet your needs.

What materials can the Press Brake process?

Our metal sheet bending machines can process various metals, such as steel, stainless steel, aluminum, copper, and more. Please specify the material and thickness, and we will recommend the most suitable machine for your requirements.

Is it easy to operate?

We will send you manual and guide video in English, I can teach you how to operate the machine. lf you still can not learn how to use it, we can help you by Team viewer online help software.Or we can talk by phone email or other contact ways.

What is your guarantee. in case the machine breaks down?

The machine has one year guarantee. If it breaks down, generally speaking our technician will figure out what the problem may be, according to client's feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

How will you do the after- sale service?

We will firstly check your problems online through Team viewer,E-mail, Whatsapp or other contact way, if it is easy to handle it, we will guide you online to fix it or send you the spare parts for replacement.

What is your equipment lead time?

The lead time for a metal sheet bending machine is typically around 4 weeks, depending on the model and customization options.

How will you do the package and shipping?

All of our equipment are packed in export standard cases. Express, air shipping, sea shipping are all available.