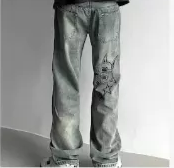

Environmental Solution: Replacing traditional washing techniques with laser technology addresses the environmental challenges associated with conventional washing processes.

Superior Speed, Power, and Efficiency: Operates at ultra-high speeds, with large power output and exceptional efficiency.

Adjustable Laser Head: Electrically adjustable for height, with adaptable processing dimensions to meet precise and large-scale manufacturing needs.

Enhanced Workspace: Upgraded table with improved dust absorption and auxiliary air blowing, complemented by smoke purifiers for superior environmental performance.

High-Definition Projector: Equipped with a high-definition projector for accurate visualization and optional cross-red light positioning system.

Safety Features: Optional safety light grid protection ensures operational safety.

Versatile Laser Options: Features original imported lasers with choices ranging from 350W to 700W to suit various power requirements.

User-Friendly Adjustments: Digital display for adjusting laser head focal length, facilitating convenient operation.

Advanced Software: Self-developed software enables multi-level engraving and natural gradient effects for refined outcomes.

Supports Bitmap and Vector Engraving: Effortlessly completes complex tasks like intricate engraving with a single click, maximizing efficiency.

Safety, Environmental Friendliness, Energy Efficiency, and Emission Reduction: Ensures safety, environmental protection, energy conservation, and emission reduction benefits.