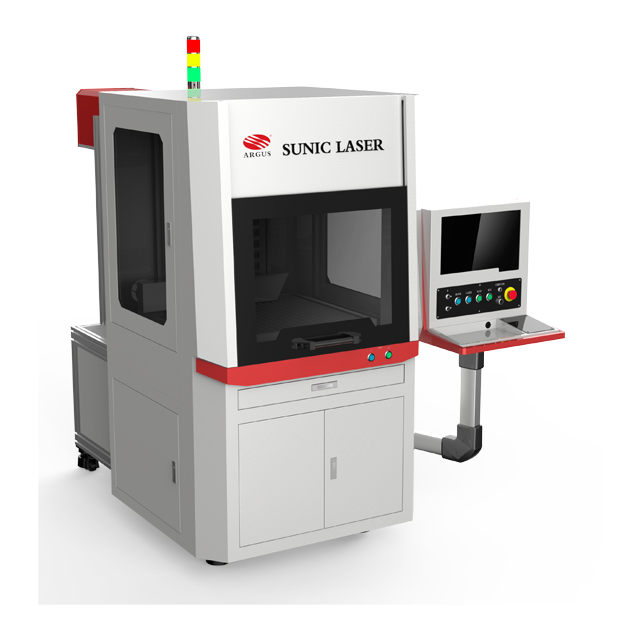

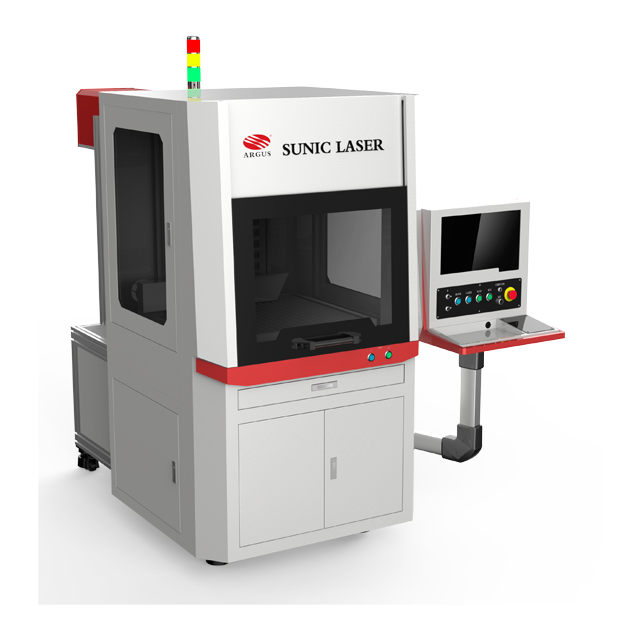

1.This machine adopts 3D Dynamic Galvanometer Control System. Original Imported metal RF laser tube. Laser power supply and cutting speed can be adjustable, maximally energy saving.

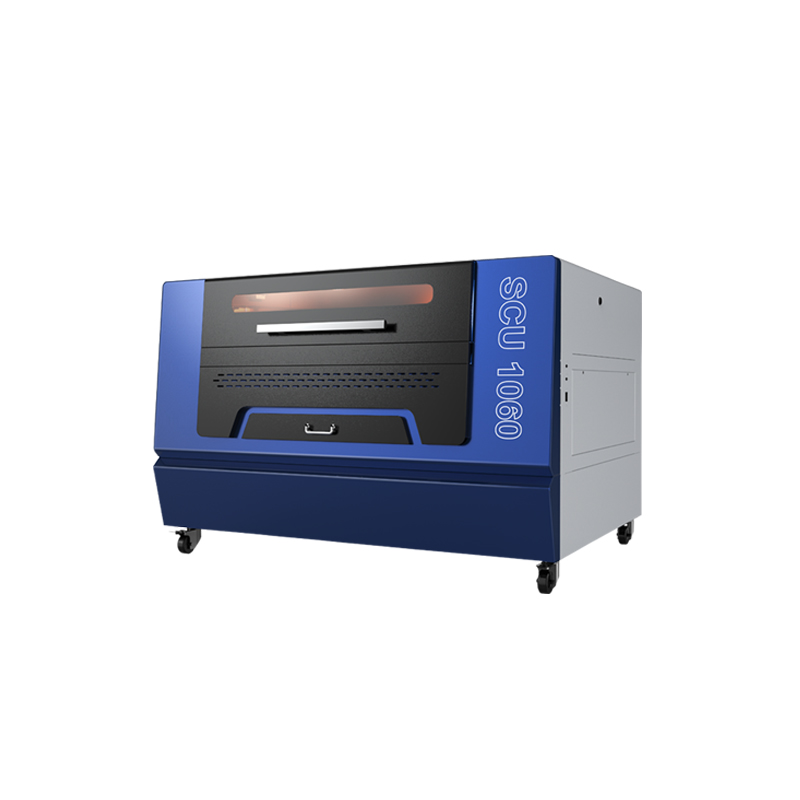

2, Fully enclosed laser optical system, no adjustment or maintenance needed, can be used directly after

installation.

3, Original imported metal RF laser tube with high laser power, excellent laser spot, stable laser generation and lifetime of more than 20000hrs, gas inside the tube can be refilled again.

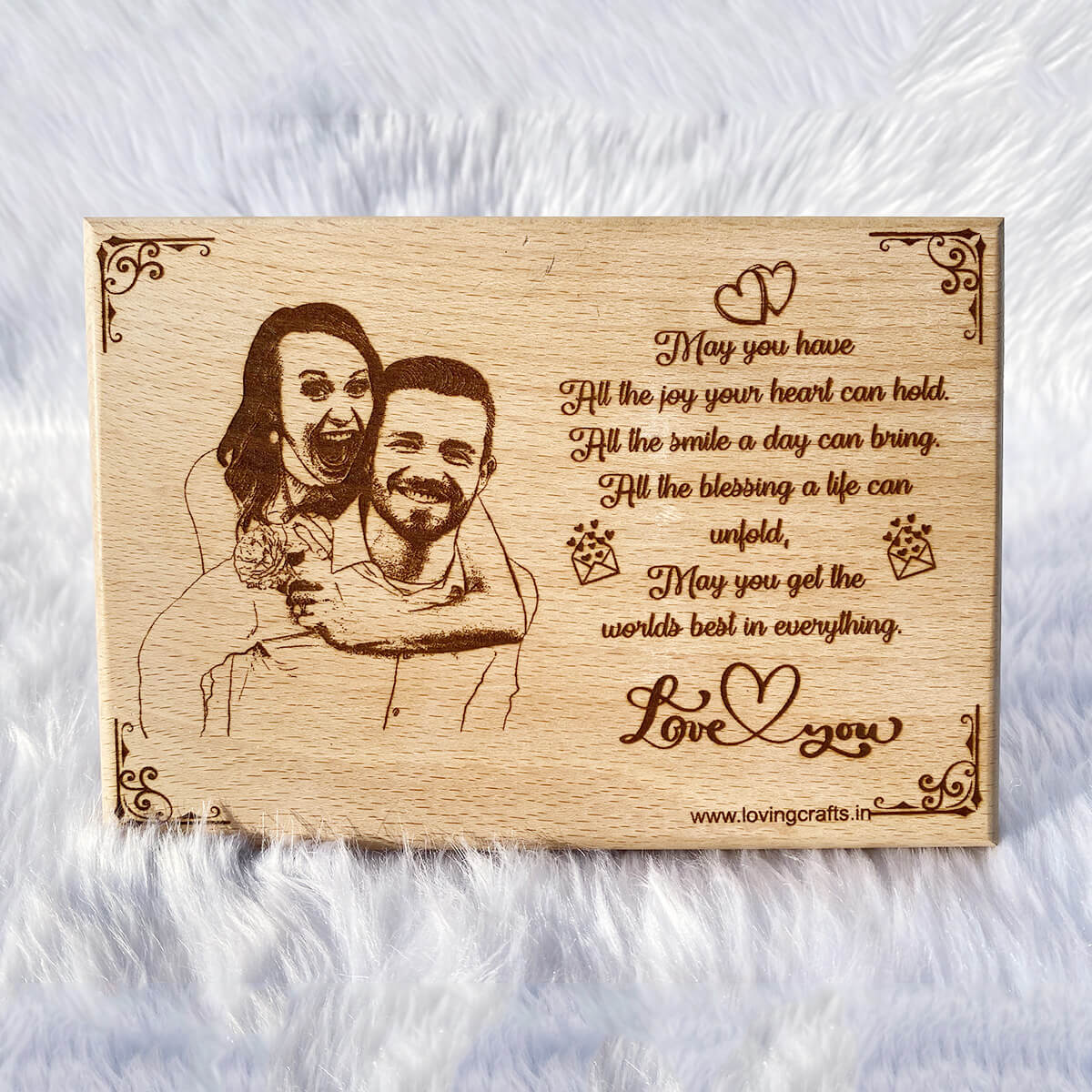

Advantages of Using Professional Wood Laser Machines

Laser marking on wood offers several advantages over traditional marking methods:

Precision and Detail: Laser machines can produce extremely fine details and complex patterns that are difficult to replicate with other tools. This precision makes them ideal for both artistic and industrial applications.

Speed and Efficiency: Laser marking is a fast process, allowing for high throughput in production settings. This efficiency is particularly beneficial for businesses needing to mark large quantities of products.

Non-Contact Process: Since laser engraving is a non-contact process, it doesn’t cause wear and tear on the material. This ensures the integrity of the wood and the longevity of the machine.

Versatility: Laser machines can work with various types of wood, including softwoods, hardwoods, plywood, and MDF. They can also handle different marking techniques, such as engraving, cutting, and surface marking.

Environmental Friendliness: Laser marking does not require the use of inks, chemicals, or solvents, making it an environmentally friendly option. Additionally, it produces minimal waste and emissions.

Professional wood laser machines offer a powerful and versatile solution for marking and engraving wood. Their precision, speed, and adaptability make them invaluable tools for artists, businesses, and manufacturers. By choosing the right machine and maintaining it properly, you can achieve high-quality results and enhance your production capabilities, opening up new possibilities for creativity and business growth.