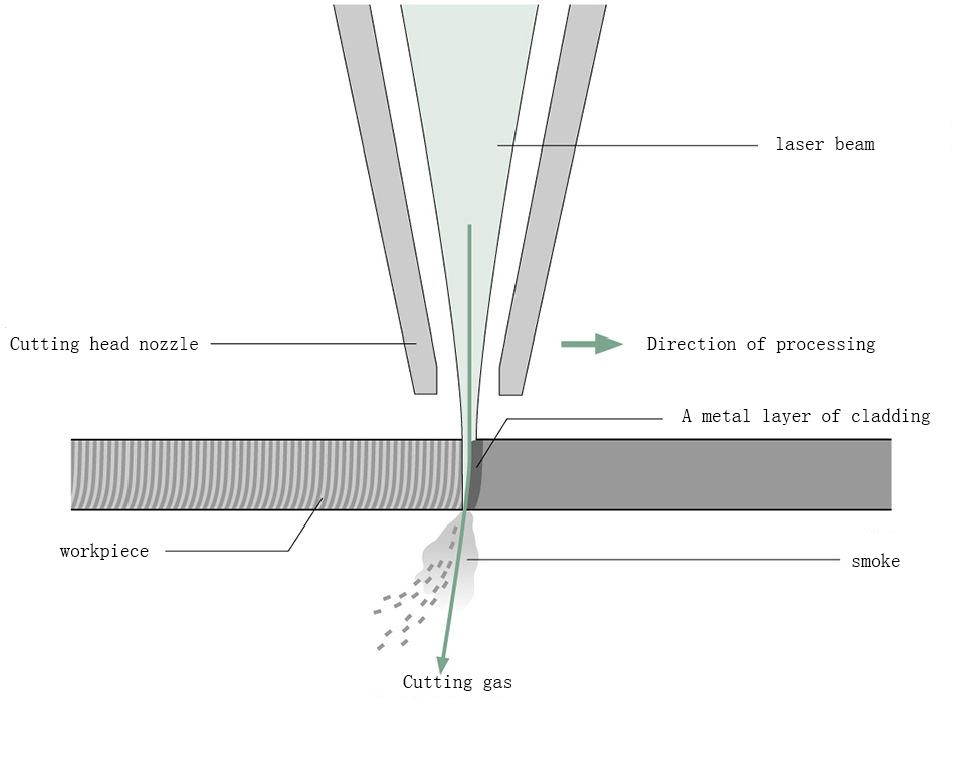

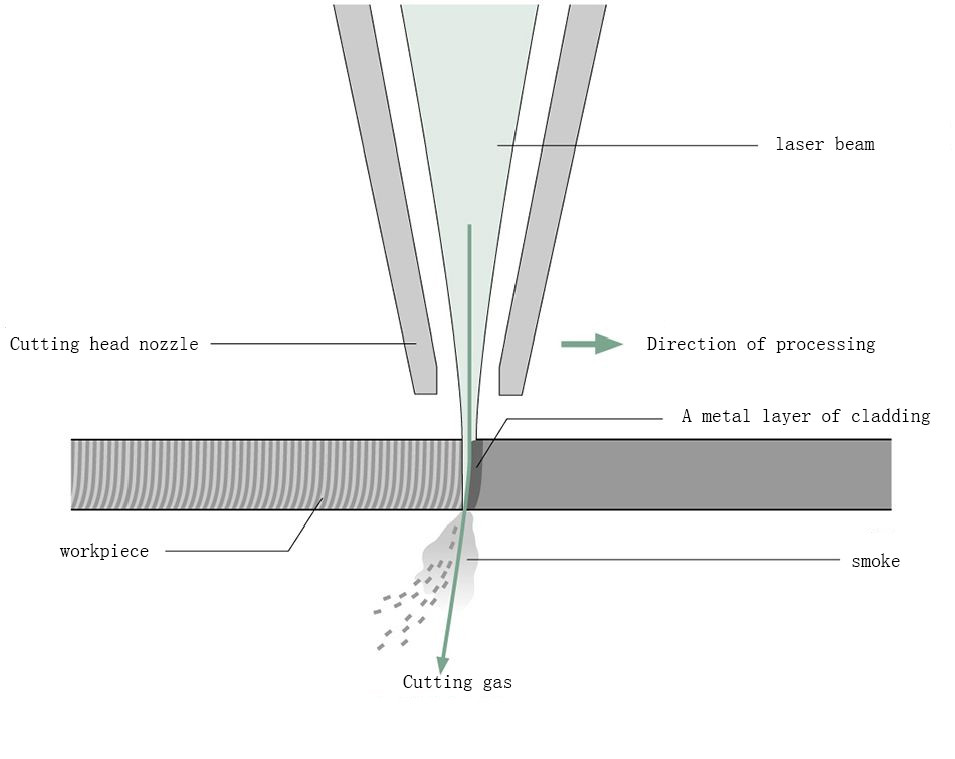

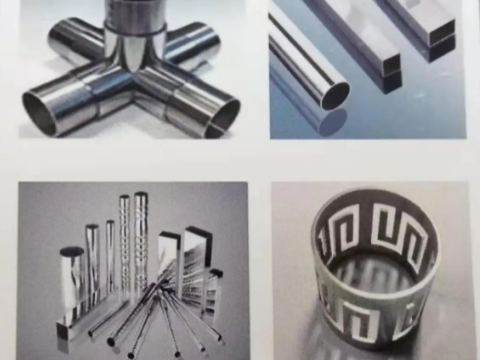

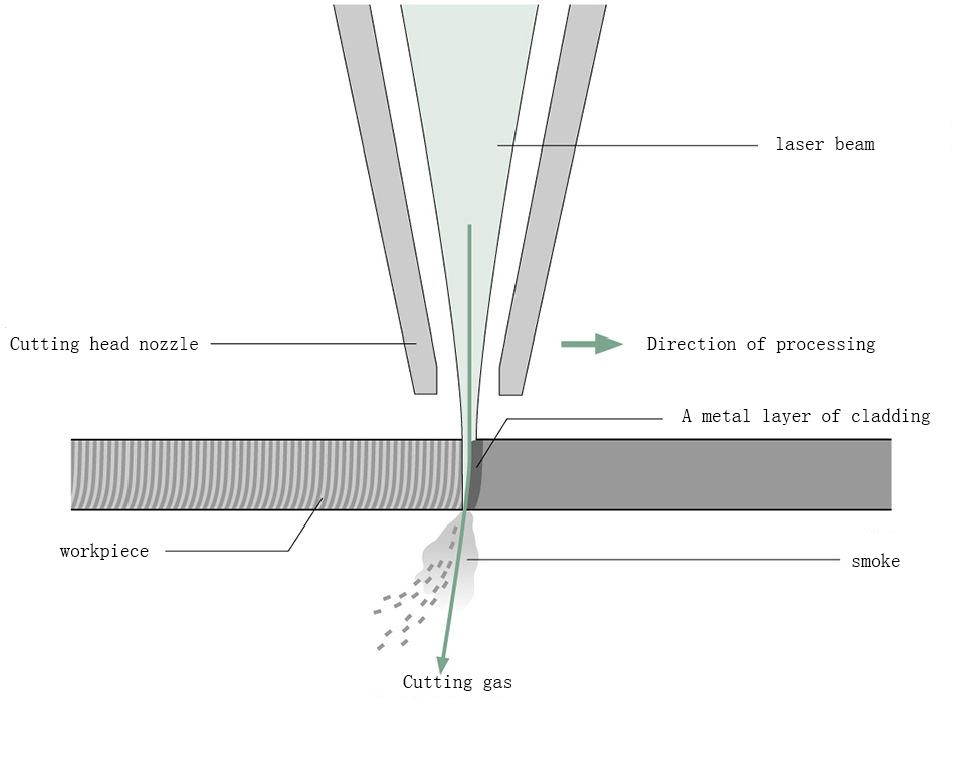

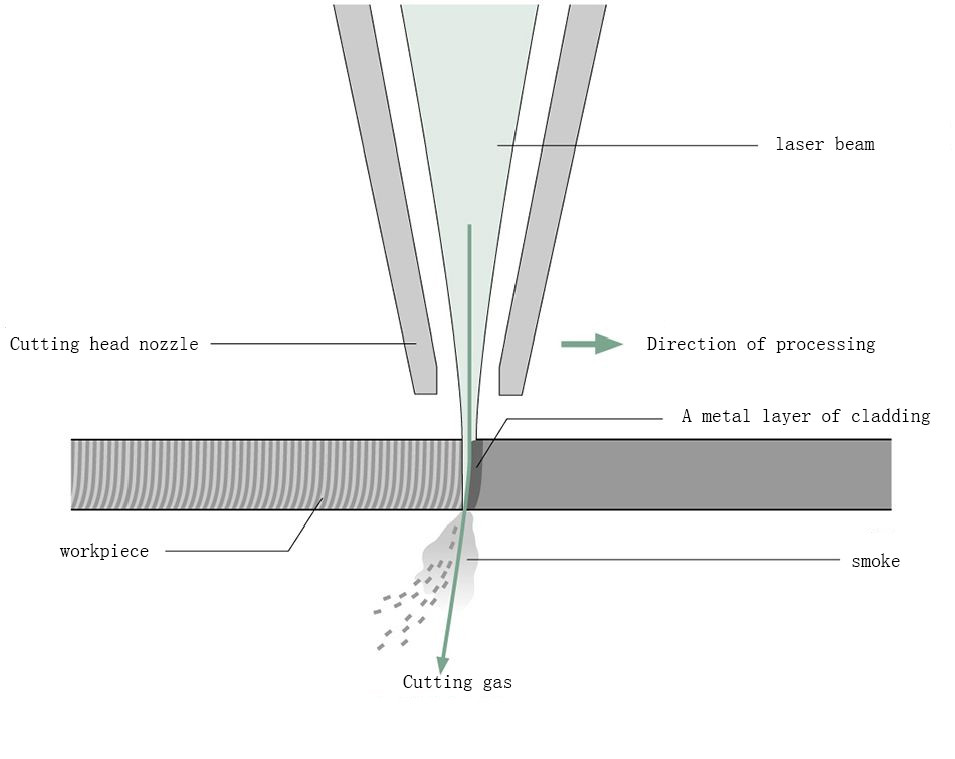

When the focused laser beam hits the workpiece, the irradiated area heats up dramatically to melt or vaporise the material. Once the laser beam has penetrated the workpiece, the cutting process begins: the laser beam moves along the contour line and melts the material at the same time. A jet of air is usually used to blow the molten material away from the cut, leaving a narrow slit between the cut part and the plate holder, which is almost as wide as the focused laser beam.

Flame cutting

Flame cutting is a standard process used when cutting mild steel, using oxygen as the cutting gas. The oxygen is pressurised to a maximum of 6 bar and blown into the cut. There, the heated metal reacts with the oxygen: it begins to burn and oxidise. The chemical reaction releases a large amount of energy (up to five times the energy of the laser) to assist the laser beam in the cutting process.

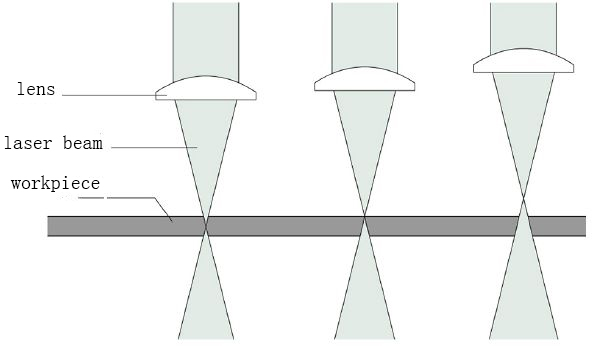

Fig. 1 The laser beam melts the workpiece and the cutting gas blows away the molten material and slag from the kerf.

Melting and cutting

Melt cutting is another standard process used when cutting metal. It can also be used to cut other fusible materials, such as ceramics.

Nitrogen or argon is used as the cutting gas and a gas pressure of 2-20 bar is blown across the cut. Argon and nitrogen are inert gases, which means that they do not react with the molten metal in the kerf and simply blow it away towards the bottom. At the same time, the inert gases protect the cutting edge from oxidation by air.

Compressed air cutting

Compressed air can also be used to cut thin sheets. Air pressurised to 5-6 bar is sufficient to blow away the molten metal from the kerf. As the air is nearly 80% nitrogen, compressed air cutting is essentially a melt cut.

Plasma-assisted cutting

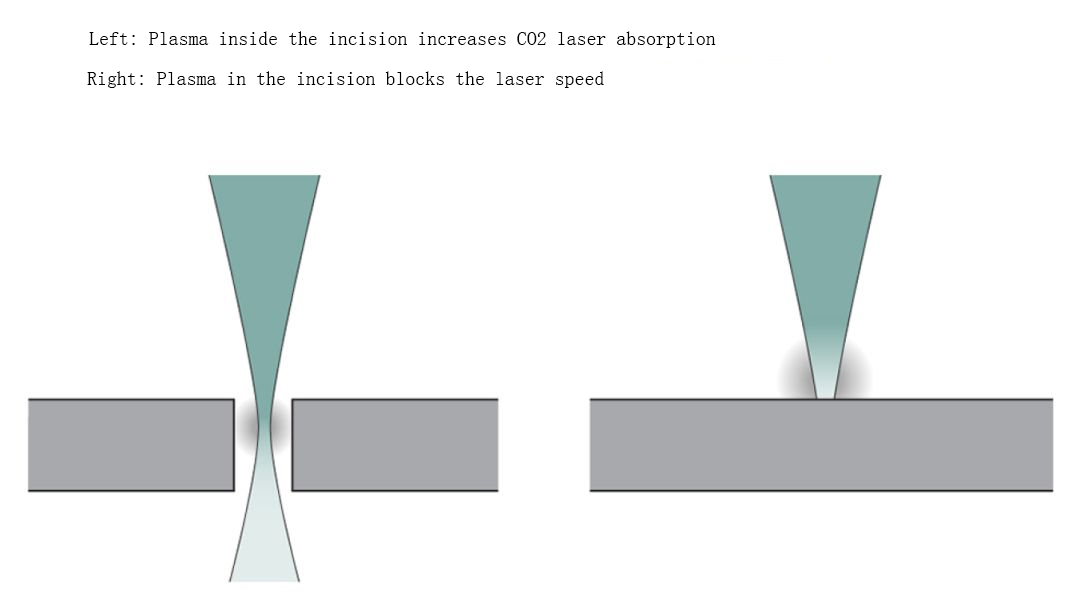

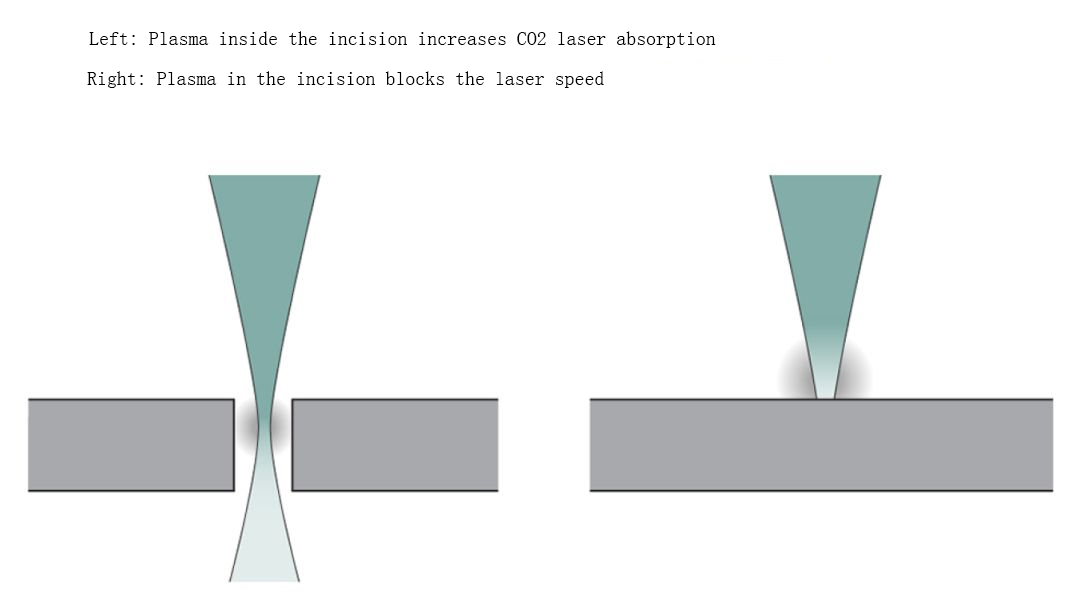

If the parameters are chosen appropriately, a plasma cloud will appear in the plasma-assisted fusion cutting kerf. The plasma cloud consists of ionised metal vapour and ionised cutting gas. The plasma cloud absorbs the energy of the CO2 laser and converts it into the workpiece so that more energy is coupled to the workpiece and the material melts faster, resulting in a faster cut. For this reason, this cutting process is also called high-speed plasma cutting.

The plasma cloud is in fact transparent in relation to the solid-state laser, so plasma-assisted fusion cutting can only be done with CO2 lasers.

Fig. 1 laser plasma interaction

Gasification cutting

Vaporised cutting vaporises the material and minimises the thermal effects on the surrounding material. This can be achieved by using continuous CO2 laser processing to evaporate low heat, high absorption materials such as thin plastic films and non-melting materials such as wood, paper and foam.

Ultrashort pulsed lasers allow this technology to be applied to other materials. The free electrons in the metal absorb the laser and heat up violently. The laser pulse does not react with the molten particles and plasma, the material sublimates directly and there is no time to transfer the energy as heat to the surrounding material. The picosecond pulse ablates the material with no visible thermal effect, no melting and no burr formation.

Fig. 3 Vaporised cutting: the laser causes the material to vaporise and burn. The pressure of the vapour causes the slag to escape from the cut.

Parameters: Adjustment of the machining process

Many parameters influence the laser cutting process, some of which depend on the technical performance of the laser and the machine, while others are variable.

Polarization

The polarisation indicates what percentage of the laser light is converted. Typical polarisation is typically around 90%. This is sufficient for high quality cutting.

Focal diameter

The focal diameter affects the width of the incision and can be changed by changing the focal length of the focusing lens. A smaller focal diameter means a narrower incision.

Focus position

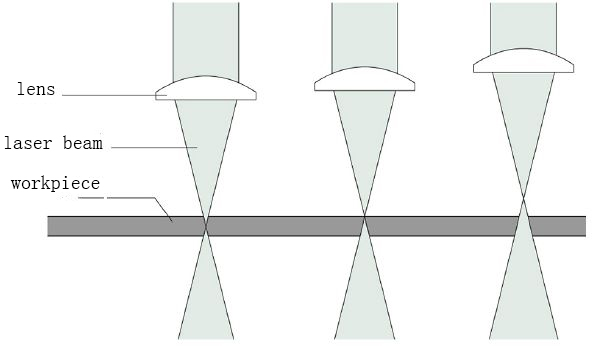

The position of the focal point determines the beam diameter and power density on the surface of the workpiece as well as the shape of the cut.

Fig. 4 Focus positions: inside the workpiece, on the workpiece surface and above the workpiece

Laser power

The laser power should be matched to the type of process, material type and thickness. The power must be high enough that the power density on the workpiece exceeds the processing threshold.

Working mode

The continuous mode is mainly used to cut standard contours of metals and plastics in millimetre to centimetre sizes. In contrast, for melting perforations or producing precise contours, a low frequency pulsed laser is used.

Cutting speed

Laser power and cutting speed must be matched to each other. Too fast or too slow of the cutting speed will result in increased roughness and burr formation.

Nozzle diameter

The diameter of the nozzle determines the flow rate and the shape of the gas stream coming out of the nozzle. The thicker the material, the larger the diameter of the gas jet and, accordingly, the diameter of the nozzle opening.

Gas purity and air pressure

Oxygen and nitrogen are often used as cutting gases. The purity and air pressure of the gases affects the cutting results.

When using oxygen flame cutting, a gas purity of 99.95 % is required. The thicker the steel plate, the lower the gas pressure used.

For melting and cutting with nitrogen, a gas purity of 99.995 % (ideally 99.999 %) is required, with higher air pressure required for melting and cutting thick steel plates.

Table of technical parameters

In the early days of laser cutting, the user had to decide on the setting of the processing parameters himself through trial runs. Nowadays, the proven processing parameters are stored in the control unit of the cutting system. For each material type and thickness, there are corresponding data. The table of technical parameters makes it possible to operate the laser cutting machine smoothly even for people who are not familiar with this technology.

Laser cutting quality evaluation factors

There are many criteria for determining the quality of laser cut edges. Criteria such as burr form, depression and grain can be determined by the naked eye; perpendicularity, roughness and kerf width need to be measured using special instruments. Material deposition, corrosion, heat affected areas and distortion are also important factors in measuring the quality of laser cutting.