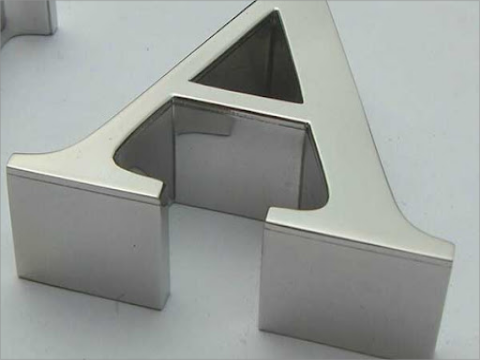

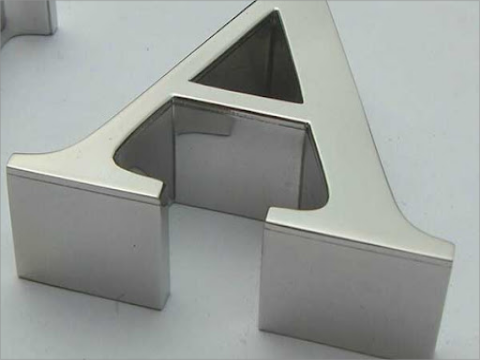

Laser welding machine for advertising letters.

Advertising word welding machine, also known as advertising word laser welder, is to weld objects with high-energy pulsed laser. The laser power supply discharges the xenon lamp pulses to produce a certain frequency and pulse width of the light wave, and through the focusing cavity radiation into the crystal, that is, the YAG crystal. The crystal emits light by resonance and sends out 1064 nm pulsed laser light, and then expands the beam, reflects, focuses and then welds.

Advantages:

Good effect: no blackening, deformation, firmness, no grinding after welding, high precision.

High efficiency: the equipment is ready to use, simple operation, welding speed is 8-10 times of the traditional process.

Low cost: no consumables, no surface treatment, no need to hire professionals at high salaries. Ordinary workers can learn immediately, comfortable operating environment, easy to weld complex fonts.

High stability: UK imported laser, service life of 8-10 years, stable performance, high power, xenon lamp out more than 8 million times, 24 hours of continuous operation.

Flexible optical path: can be moved up and down, the laser head can be rotated 360 degrees. Adopt extended light path, suitable for welding of various font type. Standard models and dual optical paths are available, small letters are welded with a hard optical path, and large letters are welded with a 5-meter long fiber optic welding head.

Mold laser welding machine:

Standard welding machine is also known as mold welding machine, laser welding machine, laser welding machine, laser cold welding machine, laser argon welding machine, laser welding machine and so on. As a new type of welding method, the standard welding method is mainly for thin-walled and precision parts, which can realize spot welding, butt welding, stack welding, sealing welding, splicing welding, penetration welding, filler welding, seam welding, gas-tight welding and so on, and can adapt to a variety of different welding paths. Higher depth ratio, smaller width, smaller heat-affected zone, smaller deformation, fast welding speed, flat appearance, no or simple treatment after welding, high quality, no porosity, can be precisely controlled, small focusing, accurate positioning, easy to realize automation.

Advantages:

Compared with other welding methods, small welding point; small heat-affected zone, no deformation of thin-walled metal, fast welding speed, high positioning accuracy; no need to use self-melting welding, high strength of weld, no pollution, no holes, firm and beautiful. Laser welding of electronic components will not damage the seals and integrated circuits; it can improve the appearance and performance stability of the product and enhance the competitiveness of the product.

Jewelry laser welding machine.

Laser spot welding is the use of high-energy laser pulses to locally heat a small area of the material, the energy of the laser radiation spreads to the inside of the material through heat conduction, melting the material to form a specific molten pool. Laser spot welding machine (jewelry spot welding machine) can weld the same or different materials.

Fiber Conduction Welder.

Fiber-optic conduction laser welding machine is a laser welding equipment that couples a high-energy laser beam into an optical fiber, transmits it over a long distance, collimates it into parallel light through a collimating mirror, and then focuses it on the workpiece to be welded. For difficult to weld parts, flexible sensing non-contact welding is used for greater flexibility. The use of fiber optic transmission laser welding machine allows for time and energy splitting, and multiple beams can be processed simultaneously for more precise welding.

Advantages:

High stability and reliability, 24 hours stable operation.

Optional CCD camera monitoring system for easy observation and precise positioning.

Uniform energy distribution in the weld joint, better welding characteristics required.

Suitable for all kinds of complex weld seams, spot welding of various equipments and seam welding of thin plates within 1mm.

Multi-function laser welding machine.

Utilizing high-energy laser pulses to locally heat a tiny area of the material, the energy of the laser radiation spreads to the inside of the material through heat conduction, melting the material to form a specific molten pool. This new welding method, mainly for thin-walled materials, welding precision parts, can realize a variety of welding methods such as spot welding, butt welding, stack welding, sealing, etc., with high depth-to-width ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful welding, no or simple treatment after welding, high welding quality, no air holes, controllable, small focusing, accurate positioning and easy to realize automation.