Laser cleaning is used as the first process in industrial production. It can not only effectively remove rust and dirt, but also cause a chemical reaction on the surface of the substrate to form a protective layer to prevent the substrate from re-rusting and improve its corrosion resistance. At present, laser cleaning technology has been applied to various fields such as military industry, industrial production, microelectronics, cultural relics protection and medical treatment.

1. Application in the field of military industry

In the field of military industry, the earliest American scientists proposed to use laser to remove the paint of military aircraft, and made related research, but because the laser equipment was expensive, large and cumbersome at that time, it only stayed in the laboratory research stage. Since then, with the development of laser equipment Progress and perfection provide convenience for laser cleaning.

My country's Luo Hongxin et al. used continuous CO2 lasers to remove paint from aircraft skin simulation samples. The laser power was 30W/mm² and the scanning speed was 400mm/min. The old skin paint could be removed at one time without damage to the substrate. Zheng Guang et al. conducted a series of performance tests on the TEA CO2 laser aircraft skin after depainting on the basis of predecessors. The results showed that the tensile strength, fatigue strength and Vickers hardness of the aircraft skin after depainting were compared with the matrix. There is no change, and the corrosion resistance has increased; under the premise of not causing gas breakdown on the target surface, the higher the energy density of the laser and the narrower the pulse width, the more conducive to paint removal. At present, the old paint layer with a thickness of 1mm and an area of 36m² can be completely removed within 1 hour by laser cleaning, and the skin stripping of a Boeing 737 aircraft can be completed within 48

hours. The above is enough to show that the application of laser cleaning technology in the treatment of aircraft skin paint removal is a milestone.

Laser cleaning also plays a huge role in other military equipment. Hou Suxia et al. used CO2 lasers to clean the mold on the surface of military equipment. According to the principle of gasification and decomposition of the bacterial body during laser irradiation or micro-explosion, a small military laser cleaning equipment was developed, which effectively prevented the mold from corroding and damaging the weapon equipment. Oxidation eliminates the influence of the bioelectric bridge formed by mycelium on the equipment circuit, greatly reducing the manpower and material resources for cleaning weapons and equipment. Aiming at the technical problems of rust removal and paint removal in ammunition repair, Song Guifei and others used a 20W fiber laser to carry out a rust and paint removal test on ammunition. Metallic luster, and the matrix structure is uniform without damage; the surface temperature of the material has almost no change, indicating that the laser is used for the surface treatment of hazardous explosion devices, and will not cause explosion due to thermal effects. It is only necessary to properly handle the laser characteristic parameters and surface treatment quality relationship to work efficiency.

In the maintenance and manufacture of military equipment, laser cleaning can improve the efficiency of equipment maintenance, reduce the oxidation of the surface of weapons and ammunition, and provide a strong guarantee for military equipment and army combat effectiveness.

2. Application in the industrial field

In the field of industrial production, mechanical equipment has been in service for a long time, and a large amount of pollution layers such as oil, waste paint, rust and carbon deposits have accumulated on the surface of parts. After using the TEA CO2 laser to clean the long-serving iron nails on the industrial equipment, the SEM inspection and analysis found that the original galvanized coating on the iron nails was intact, and only the oil and other pollution layers on the surface were removed.

Y.C.Guan et al. used a pulsed Nd:YAG laser (1064nm) to clean the carbonaceous deposits of diesel engine pistons. After XPS and SEM/EDX, it was found that the Fe3C on the surface of the diesel engine matrix was completely removed, and the carboxylate was also significantly removed. reduce. According to the requirements of the welding process, Luo Ya et al. carried out laser cleaning pretreatment on TC11 titanium alloy before welding, and studied the influence of laser cleaning on welding performance. The experiment adopted POWERLASE Rigel i400 nanosecond pulsed solid-state laser, the cleaning power was 150W, and the line spot The length is 25mm, the scanning rate is 10mm/s, and the argon gas protection is used to conduct vacuum electron beam welding and analysis tests on the cleaned and uncleaned test pieces respectively. The results show that the oxide film on the surface of the titanium alloy can be completely removed after laser cleaning and pollutants, and the quality of the weld is first-class, and there are no welding defects inside. It can be seen that laser cleaning technology can effectively improve the welding quality compared with the traditional pre-weld sample processing method.

N. Maharjan et al. used a femtosecond laser with a wavelength of 790nm, 130fs pulse, and a power of 1.5W to clean aviation parts, which can effectively remove surface pollutants. After testing and analysis, it was found that the oxygen content on the surface decreased significantly after cleaning. Under the circumstances, the application of femtosecond laser in cleaning technology can improve the cleaning efficiency. Ni Jiaming et al. used laser cleaning technology to perform local laser cleaning on the aluminum alloy anodic oxide film, and carried out butt welding on the welded test plate after cleaning, and evaluated the quality of the weld through X-ray detection. Tensile test was performed to test the effect of removing the oxide film on the performance of the weld. The results showed that the anodic oxide film was thoroughly cleaned. The tensile strength of the aluminum alloy joint after laser cleaning was 298~303MPa, and the tensile elongation at break was 6.2%~6.5 %, the performance range of laser cleaning welds and mechanical scraping welds is consistent, the welding pool is clean during the welding process, and the welds have no internal defects such as aggregated pores and impurities, which greatly improves the weldability of aluminum alloys.

S. Genna et al. used laser cleaning technology to clean the surface of carbon fiber reinforced plastic (CFRP), and explored the pretreatment process of laser-assisted joining (LAJ) of carbon fiber cloth. Using Yb:YAG fiber laser with a power of 30W, the results showed that the laser Cleaning as a pretreatment can significantly increase the strength of the joint, and when other parameters are optimized, the strength is twice that of the sample; laser cleaning can remove the first epoxy base layer from the laminate, which is extremely beneficial to improve the connection shape. Qiao Yulin et al. used a high-repetition frequency and high-energy laser with a wavelength of 1064nm to conduct a laser cleaning test on the carbon on the surface of titanium alloys, and analyzed the effect of cleaning speed on the morphology and composition of carbon deposits on the surface of titanium alloys cleaned by laser. The results showed that when When the laser power is 500W, the pulse width is 20ns, the frequency is 18kHz, and the scan width is 5cm, the cleaning effect and quality are the best when the cleaning speed is 7cm2/s; if the cleaning speed is too small, spot marks will appear on the surface of the titanium alloy. There will be some micro-fusion in the center of the spot.

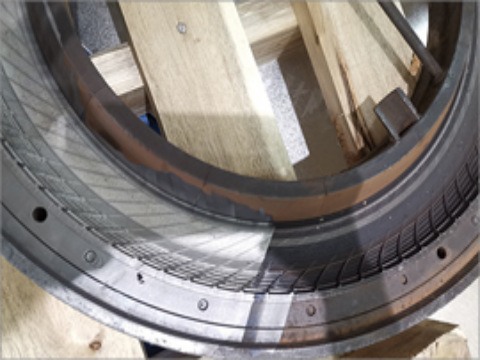

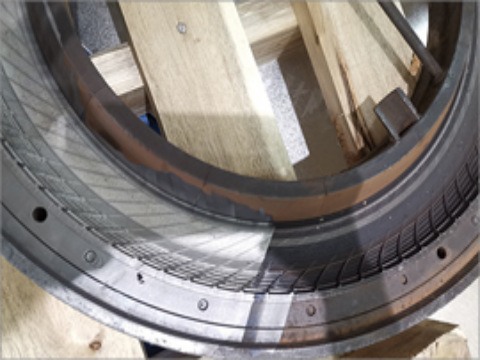

Laser cleaning technology also plays an irreplaceable role in the rubber production industry. Due to the long-term service of tire molds, a large amount of pollutants are deposited on the surface, which has a huge impact on production accuracy. Laser technology can be used for "green" cleaning on the surface of tire molds .

The application of laser cleaning technology in industry has greatly improved the carbon deposition effect and welding process quality. It can efficiently clean the carbon deposition on the surface of different substrates, reduce welding defects, and improve the weldability of materials; Save the production cost of the enterprise and improve the production efficiency of the enterprise.

3. Application in other fields

In other fields such as microelectronics processing, cultural relics protection and medical treatment, the application of laser cleaning technology has also made great progress. Polyimide is a dielectric material for the internal connection structure of electronic component packaging films. Excimer lasers with wavelengths of 248 and 193nm can effectively peel off organic polymers to prevent Pd and TiCrW from polluting polyimide. In terms of circuit board cleaning, the KrF laser is widely used, with a pulse energy of 300mJ, a pulse width of 20ns, and a frequency of 1Hz, which can clean the passivation film on the surface of the circuit board.

Laser cleaning of cultural relics, handicrafts and buildings has been widely used. In Europe, people have cleaned various buildings, such as the Martyrs' Tomb in Poland and the West Administrative Palace in London. Using KrF excimer laser, the laser with a wavelength of 1.06nm can effectively clean the dirt of stone carvings and other handicrafts (such as limestone, marble and bone) without damaging the cultural relics themselves. Although the application effect of laser cleaning technology is very reliable, not all cultural relics can be cleaned by laser. damaged.

In medical treatment, laser cleaning has been applied in the fields of tattoo cleaning and eyebrow tattooing. In the past, the use of chemical drugs to clean or cover up wrinkles not only could not completely remove the pigment, but also left scars and even endangered health; the laser was applied to the affected area, and the energy transmitted by the laser was used to quickly crush the pigment particles and pass through the skin. Metabolic methods such as skin peeling and cell phagocytosis remove tattoo pigments, and the effect of laser cleaning is good, and there is no harm to the patient's skin.

There are also scholars who combine laser cleaning technology with the food industry, using YAG nanosecond pulse lasers to clean food processing residues on 304 stainless steel plates under different processing conditions.

T. Uthaijunyawong et al. used a suitable power (12W) laser to clean food utensils without damaging the surface of the substrate, and obtained a 17% cleaning area. The laser cleaning was quantitatively analyzed by GC/MS/SIM technology Smoke from 16 polycyclic aromatic hydrocarbons (PAHs) smoked marinades before and after. Tests have shown that in laser exhaust, it was found that 2-3 ring polycyclic aromatic hydrocarbons accounted for about 86% of all polycyclic aromatic hydrocarbons, and the total PAH concentration value was much higher than the 1ng/m³ polycyclic aromatic hydrocarbons stipulated in the WHO Therefore, a proper suction system should be installed during laser cleaning to prevent secondary PAH contamination of food. The process of laser cleaning food utensils can reduce cleaning time, reduce the use of toxic waste, and reduce the occupational risk of operators in the process.