Laser Rust Cleaning Machine Function Introduction:

Laser Rust Cleaning Machine Function Introduction:

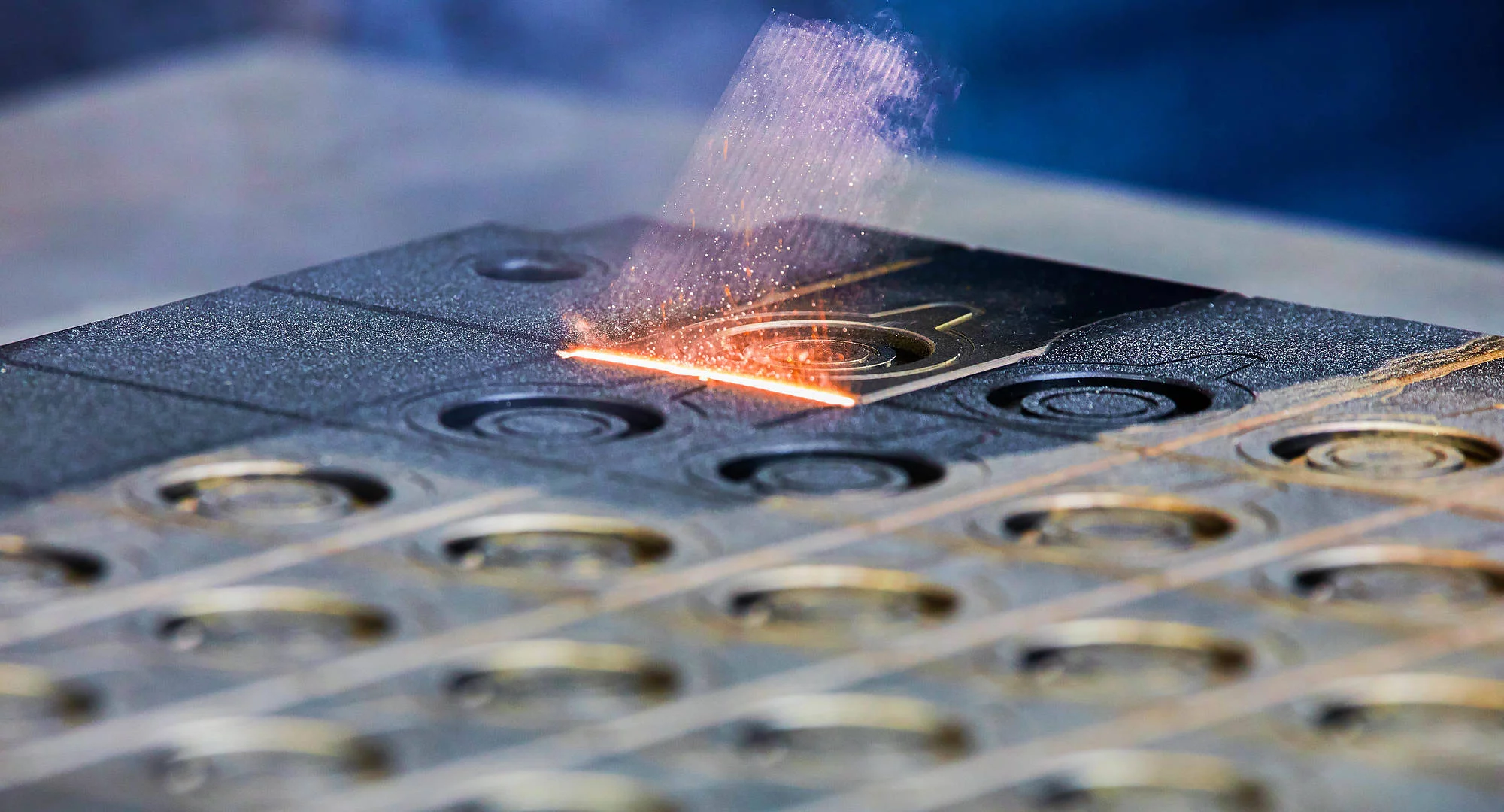

1. Laser cleaning machine quickly removes metal, paint and thick coatings, rust on any hard surface. It also removes all kinds of contaminating oxides, grease, resin, glue, residue, and even rough metal surfaces. Removes motor and cooking grease stains, etc.

2. The laser rust removal can non-destructively detect post-weld oxides. Handles pre-weld residue and slag cleaning.

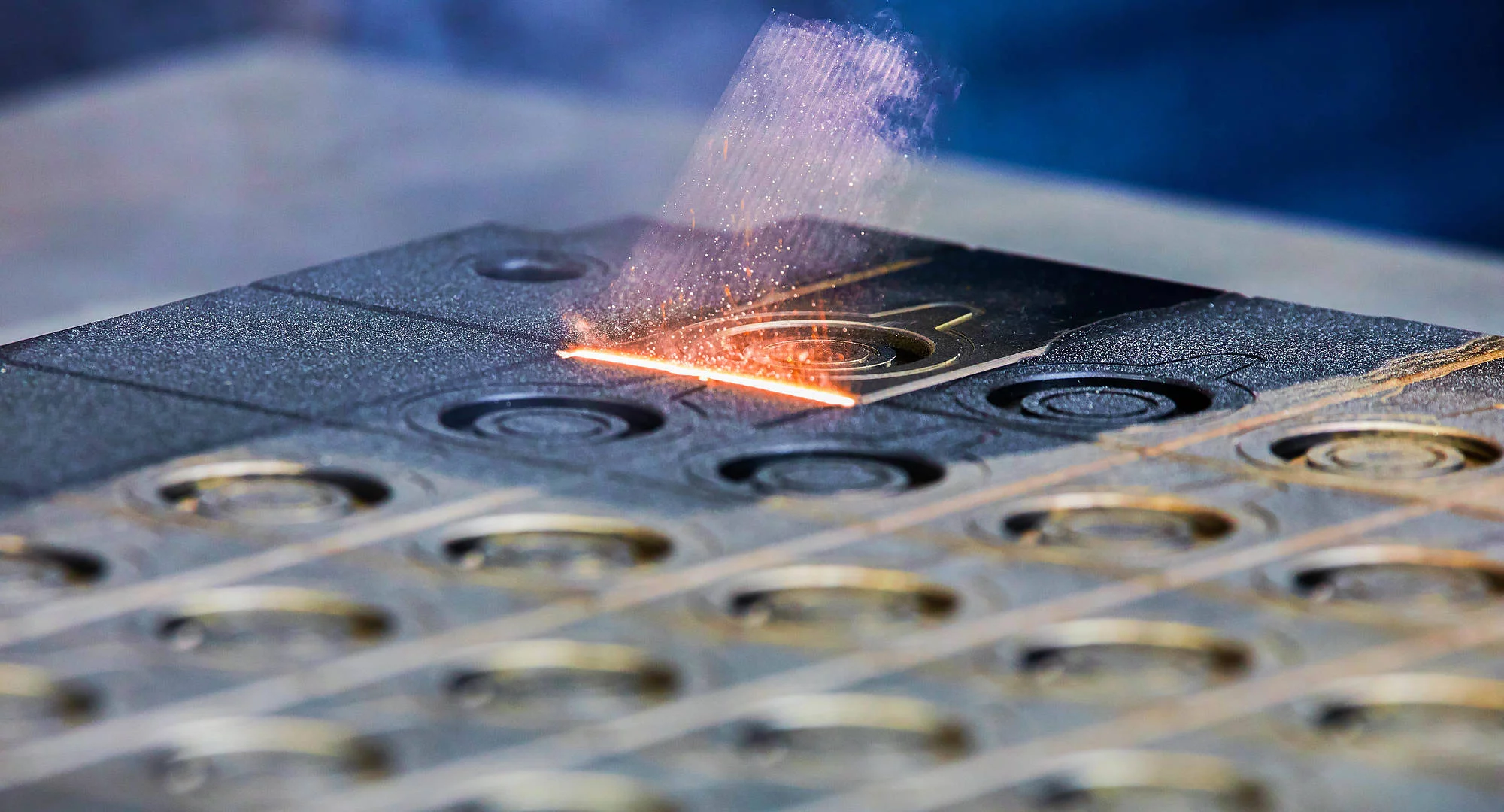

3. The laser cleaning machine can clean the mold. Such as rubber mold, food grade stainless steel, vat mold, etc. After production processing, aging stains on precision parts are also removed. The powerful clean laser machine series can efficiently clean and maintain precision parts.

1000W 1500W 2000W Laser Cleaning Machine

Fiber Laser Rust Removal Machine For Cleaning Rusty Metal

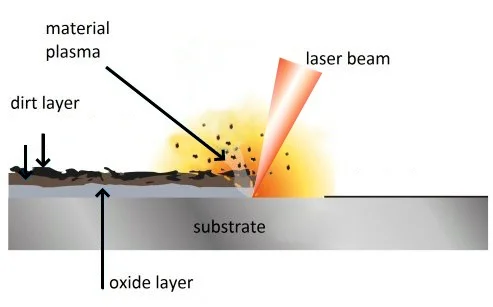

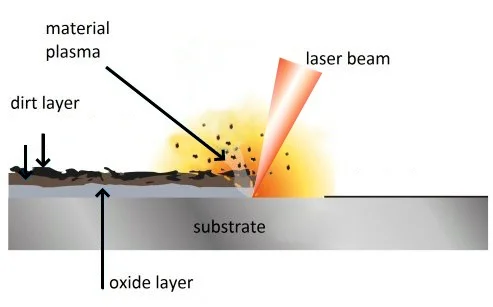

1. In the solid surface to produce a mechanical resonance phenomenon, is the surface of the dirt layer or condensation debris; 2. The surface dirt layer is heated and expanded, so as to overcome the adsorption force of the basic material to the dirt particles and the surface of the object is separated from the surface of the object; 3. Instant to make the dirt molecules evaporate, gasification or decomposition.

Product Advantages

200w 300w 400w 500w portable fiber laser cleaning machine. For Rust removal, paint removal, oil removal, cultural relic restoration, glue removal, coating removal, etc. 1000w laser clean machine rust removal,1000w 1500w 2000w option.

1. No consumables, no chemical pollution, saving energy and electricity;

2. No contact, no friction, and no stress can protect the surface of brittle materials, and minimize damage to the substrate;

3. It can remove pollution particles below the nanometer level, and the cleanliness is high;

4. Optical fiber transmission can be moved and operated, precisely positioned for cleaning, and can also clean areas that are not easily accessible;

5. Synchronous cleaning and synchronous processing to achieve zero discharge during the cleaning process;

6. It can realize fast cleaning of heavy pollutants and high-speed cleaning of light pollutants;

7. Laser cleaning can solve problems that cannot be solved by traditional cleaning methods;

8. Wide range of applicable materials for laser cleaning;

How Much Does A Fiber Laser Cleaning Machine Cost?

The cost of handheld fiber laser cleaning machines varies greatly in accrodance with different laser power. A new fiber laser cleaner can cost from $4.2k to $13k. Specify your needs and get a quote for ARGUS fiber laser welder machine now.The delivery time is within 7 days.

The laser cleaning machine can efficiently remove resin, oil stains, stains, dirt, rust, coating, plating, and paint on the surface of the work piece, meeting the cleaning requirements of complex shapes and fine positioning in the industrial processing field, achieving a cleaner cleaning effect with higher cleanliness, and a higher overall cost.

|

Product Details

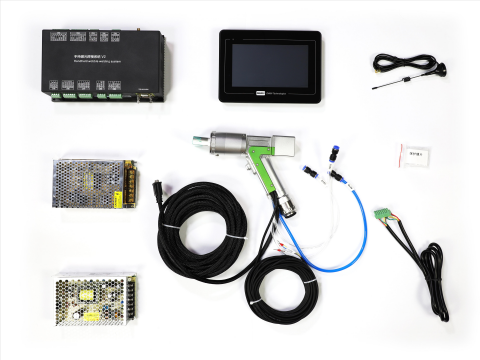

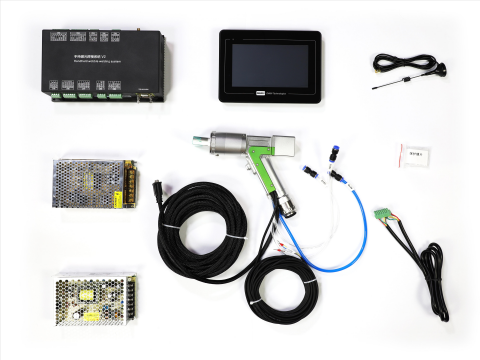

Cleaning Head

The beam emitted by the laser cleaning gun can achieve precise positioning and precise cleaning without affecting other surrounding areas

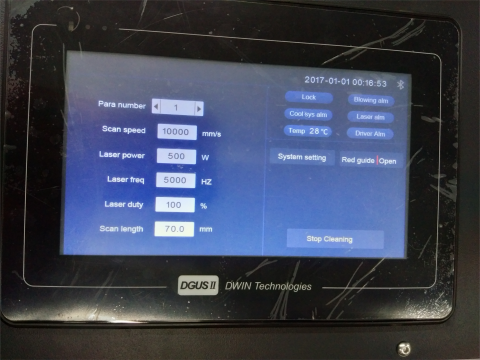

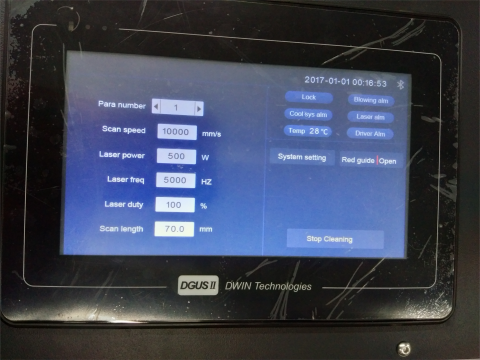

Control Panel

Strong compatibility

Various light emssion modes

Maintenance-free, long service life

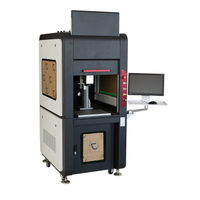

Laser Source

Using well-known brand laser generators (Raycus/JPT/Reci/Max/IPG), high photoelectric conversion rate ensures the laser power and makes the welding effect better. Argus can customize different configurations to meet customer needs.

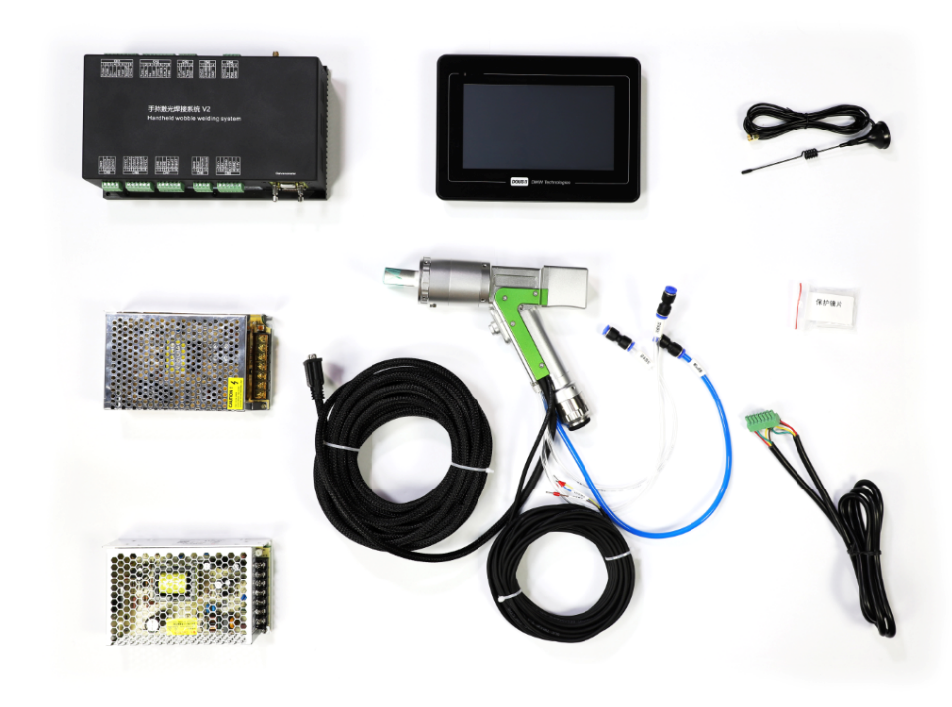

Machine Parts

Complete basic accessories •

Easy replacement •

Optional collocation •

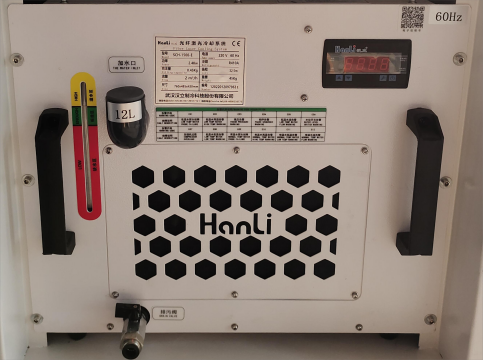

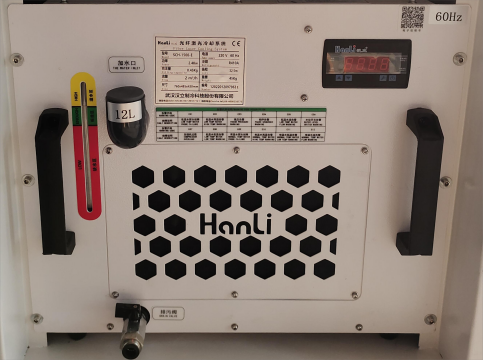

Cooling System

Specially developed for fiber laser equipment with excellent cooling effect. Stable and reliable performance, low failure rate, energy saving and high efficiency.

| Sample Display