Fiber laser vs CO2 laser is a common debate because the two technologies are easily available in the manufacturing sector. Some believe that CO2 lasers are better because of their capabilities while others say fiber lasers bring several innovations to the table which makes them a better alternative.

However, the right answer to the fiber laser vs CO2 debate depends on your application. No technology is better than the other. The best choice depends on your application and other factors like the required precision, material properties, and others.

The following text will take a look at what fiber and CO2 lasers bring to the table and try to address the fiber laser cutting vs CO2 laser cutting debate.

An Overview of Fiber Lasers

The fiber laser uses high-tech fiber optic components to deliver an intense beam of light that can laser cut different materials with ease. They are the best choice for metal processes like etching, annealing, and engraving.

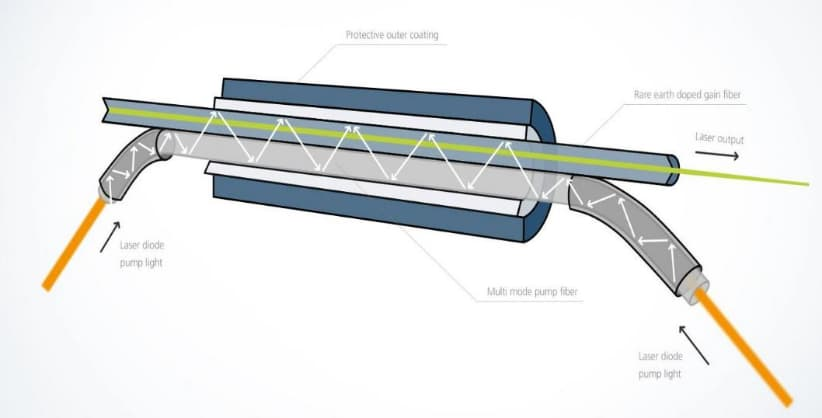

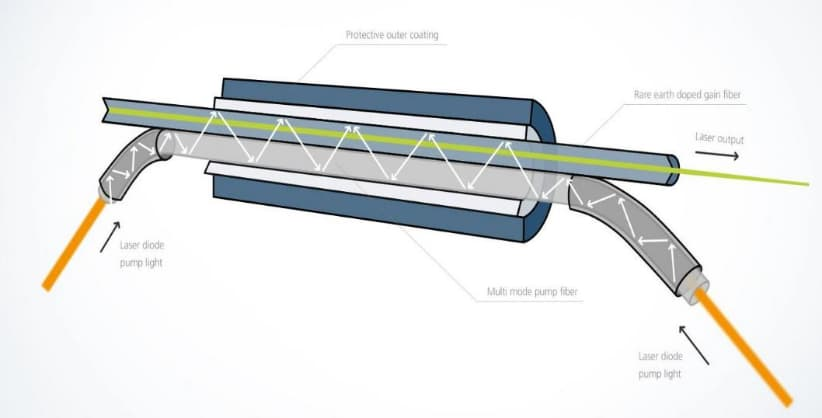

The overall concept and process of fiber lasers are extremely simple and versatile. The term doesn’t encompass the light source, which is different than CO2 lasers. The focus is on the delivery mechanism that uses fiber optics to concentrate all the light to a single point. The working mechanism of fiber laser also reflects this simplicity. The fiber optic in the laser cutter receives the light and amplifies it to the laser pointer.

The cutting head uses CNC for precision and accuracy. Moreover, the fiber optic has a series of additional focal lenses that further enhance the overall accuracy of the whole system. Finally, the laser cutter uses either NO2 or O2 as a purging gas to facilitate the cutting process.

When it comes to laser cutting, operational costs are a significant consideration. Fiber lasers, however, don’t have such maintenance requirements. This means that the overall costs of operating and maintaining the machinery are quite low. However, the initial capital requirements of purchasing a fiber laser are quite high, which makes it unfeasible for small or medium businesses.

An Overview of CO2 Lasers

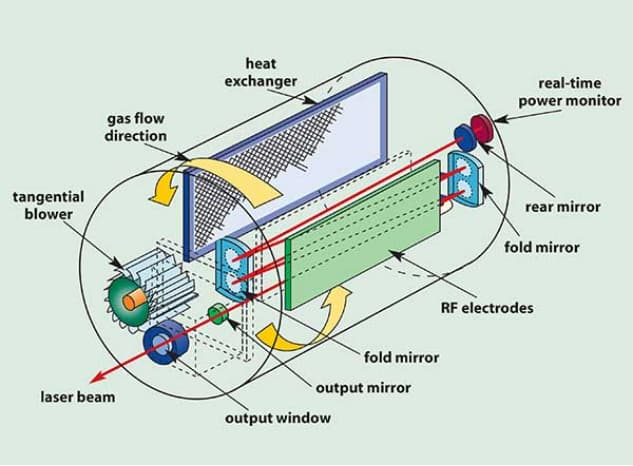

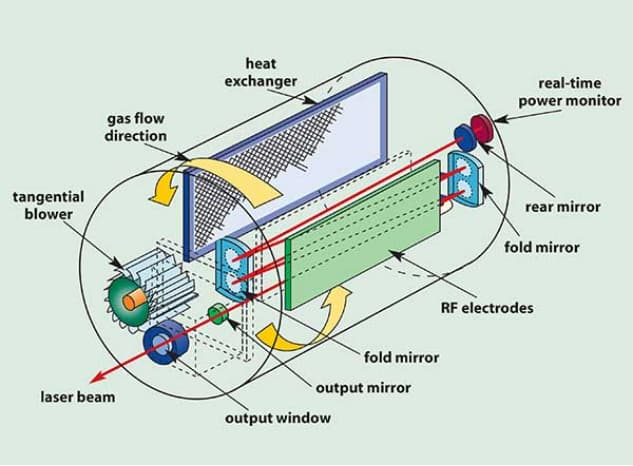

CO2 lasers use a combination of a resonator, purging gases, and high-velocity blowers to create high-powered light particles that collide with each other to deliver high-intensity light that can cut through thicker materials with relative ease.

Contrary to the fiber laser, CO2 lasers have a beam path delivery system that initially operates a little differently by using the process of reflection and refocusing rather than focal lenses like fiber lasers.

Fiber Laser vs CO2 Laser:

CO2 vs fiber laser is a significant debate that requires careful consideration of several factors. You need to consider the technical factors like the energy source and the light wavelength to the process parameters like the cutting speeds and precision. Here’s a head-on-head comparison of the most important factors to address all the questions you might have about fiber vs CO2 lasers.

1 – Energy Source

Fiber lasers use LEDs to emit light that is then concentrated by the fiber optical lenses that amplify the light to deliver results. On the other hand, CO2 lasers stimulate a mixture of gases like CO2, N2, Xe, and others to create waves that intensify to cut through different objects easily.

2 – Power Consumption

Fiber lasers are extremely efficient. In comparison to their CO2 counterparts, fiber lasers consume 30% less power, which means that they can get the job done quicker and with fewer resources.

3 – The Wavelength of Light

Both CO2 and fiber lasers operate in the infrared spectrum. Generally, a CO2 laser emits a wavelength of 10,600 nm while a fiber laser emits in the range of 780 to 2200 nm.

4 – Cutting speeds

When it comes to thinner workpieces, fiber lasers offer much better cutting speeds. In general terms, a 2 KW fiber laser will cut as fast as a 5- or 6-KW CO2 laser. The main reason behind this is the power density of fiber lasers. The optical system efficiently focuses a lot of power at a single spot and offers a much better cutting speed than CO2 lasers.

5 – Cut Precision

If you talk about the exact stability and precision, then fiber lasers will be better. However, precision has another dimension in the manufacturing sector and it deals with the smoothness of the edges. In that regard, CO2 lasers perform much better so the actual choice depends on your preferences.

6 – Cutting Range

Fiber laser machines have an overall cutting range of 13mm when it comes to metal sheets. There are some high-powered versions that can cut softer materials like Aluminum up to 30mm, but those versions are extremely expensive.

CO2 lasers, on the other hand, are only limited by their power levels. Depending on the wattage, the CO2 laser will cut through different widths easily.

the general rule of thumb states that fiber lasers are the best choice if you regularly deal with thinner parts and need faster results. For thicker parts and dealing with other nonmetals as well, CO2 lasers are a better choice.