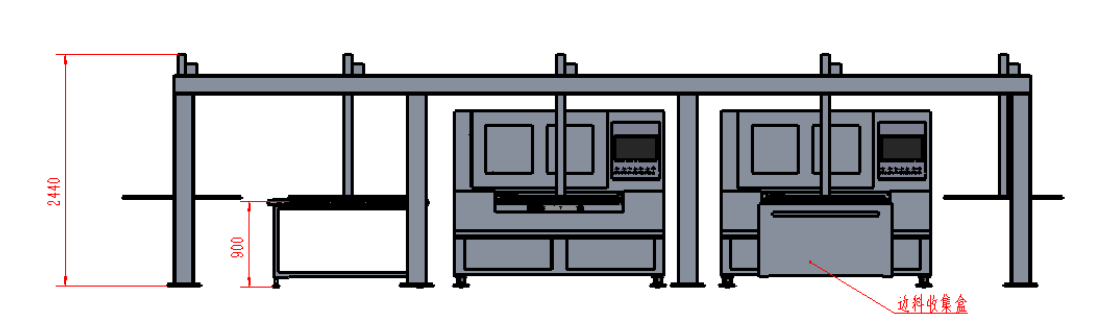

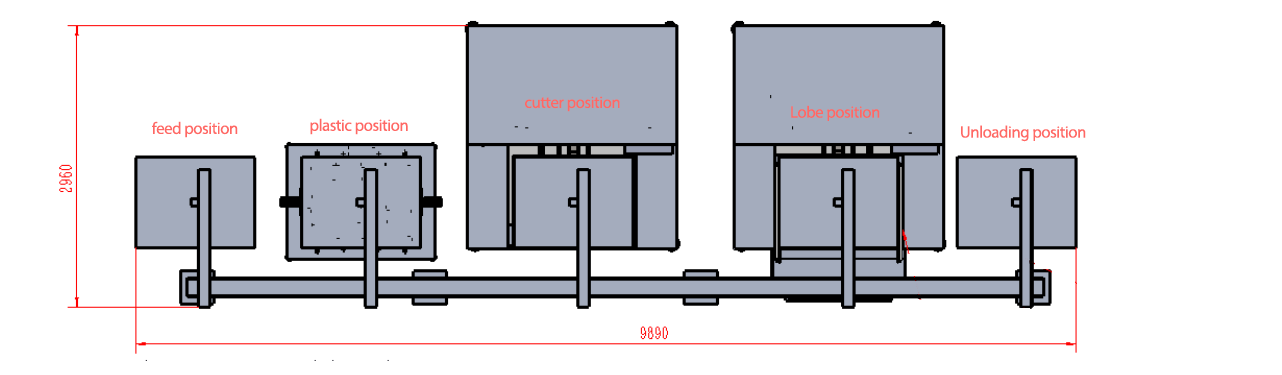

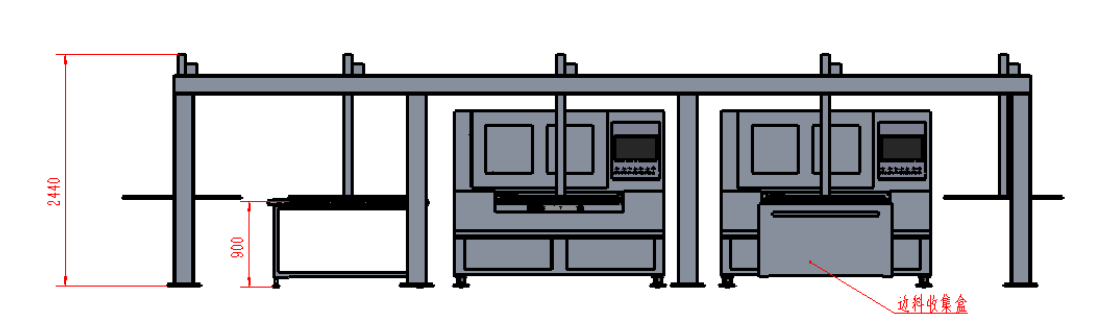

Overall View Of The Equipment

Functions and standards achieved

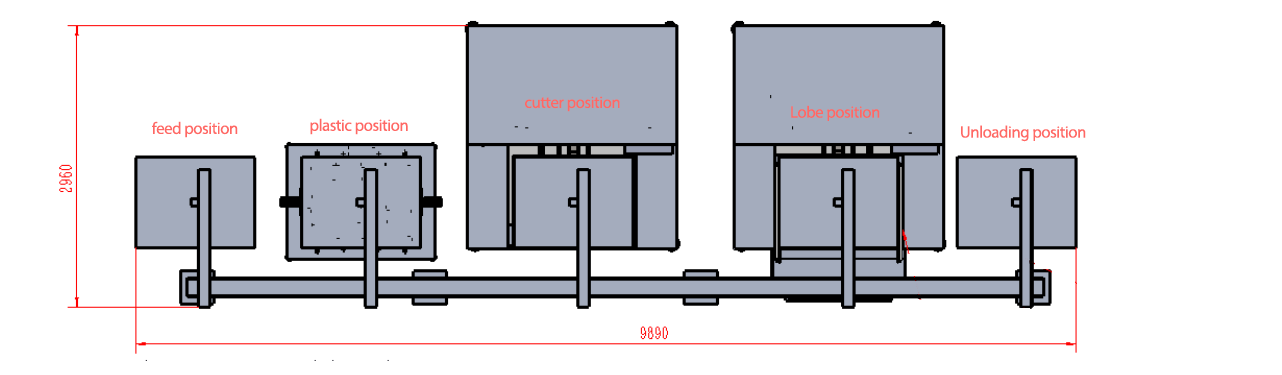

1. The equipment is equipped with upper sheet transfer + laser cutting machine + laser slicing machine + lower sheet transfer, upper/lower sheet transfer, cutting machine and slicing machine can work independently, and upper/lower sheet transfer will not be affected during normal cutting.

2. After the glass is loaded, it will be positioned by the upper sheet transfer and then transferred to the laser cutting station for cutting, and then enter the cracking station and the lower sheet transfer station in turn.

3. The upper and lower sheet transfer, laser cutting machine and laser slicing machine are equipped with separate touch screen operation and control system.

4. Product graphics can be drawn and adjusted according to the shape of the product (to meet the shaped products), and can be imported into the cutting machine, and can be called up during production.

5. Cutting parameters can be adjusted on the touch screen, and there is a product memory function, can store more than 100 varieties, set up once can be directly according to the product name call cutting procedures

6. Equipped with edge material collection system

7. Equipped with cutting cooling system

8. Equipped with software and running programme, which can be edited and modified.

9. All contact parts with the glass, can not scratch the glass, and can not leave any marks on the glass

10. Give clear requirements for the use of the environment and installation conditions of the equipment

12. Operator protection facilities and safety warning signs

Schematic Diagrams Of major Structures

Laser cutting machine:

1, marble platform: stable bearing, corrosion-resistant

2, linear motor mould X / Y axis linear motor, optical ruler, single platform. Linear motor and optical ruler through the motion controller closed-loop control, fast speed, high positioning accuracy, no contact between stator and movable when moving, no wear and tear for long-term use, basically no maintenance.

Equipment indicators:

1, marble platform flatness: ± 0.01mm

2, platform specifications: single platform

3, X / Y platform travel: 12500X950mm, cutting speed: 0-500mm / s adjustable acceleration: ≥ 10000mm / s positioning accuracy: ≤ ± 2um Repeat positioning accuracy: ≤ ± 1.5um

Schematic Diagrams Of The Main Structures

Laser Slitter:

1、Marble platform: stable bearing, corrosion resistance

2、Linear motor mould X/Y axis linear motor, optical ruler, single platform. Linear motor and optical ruler through the motion controller closed-loop control, fast speed, high positioning accuracy, no contact between stator and movable when moving, no wear and tear for long-term use, basically no maintenance.

Equipment indicators:

1, marble platform flatness: ± 0.01mm

2, platform specifications: single platform

3, X / Y platform travel: 12500X950mm, cutting speed: 0-500mm / s adjustable acceleration: ≥ 10000mm / s positioning accuracy: ≤ ± 2um repeat positioning accuracy: ≤ ± 1.5um

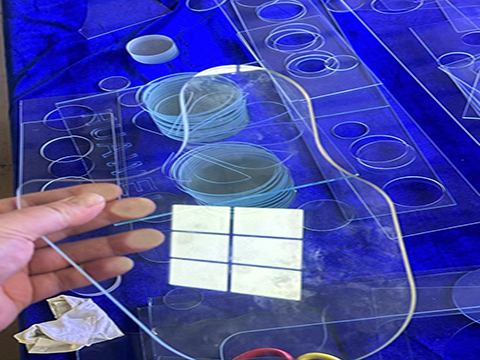

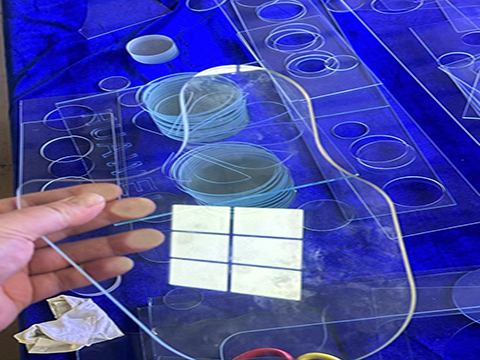

Laser Cutting Modules

1、Picosecond laser; high peak power, low heat-affected area, suitable for processing of brittle materials

2、Light path module; precise selection of light path suitable for high requirements

3、Z-axis module: cutting head, vision system, servo motor Cutting head: cutting without taper, no residue, small chipping, high strength

4、Vision system: CCD camera, lens, coaxial light source