Oil, rust, paints, or mold-release agents are hazardous contaminants for metal parts. And these contaminants gradually degrade the durability of the metal. However, it is difficult to remove rust from metal using mechanical tools. In this case, a laser rust removal machine is ideal for removing such contaminants.

The laser rust removal process is a non-contact automated cleaning method. In this case, the laser technology ensures the most effective and fastest cleaning solution. Therefore, laser rust removal machine is so prevalent in most industries. On the other hand, the laser rust removal process doesn’t require any chemical use. As a result, laser cleaners are environmentally friendly and safe. However, most food and medical industries specialize in laser rust removal machines.

Laser rust removal is a laser cleaning or laser ablation process which quickly breaks the bonds between the substrate and the rust. It ultimately cleans the projected area and gives it a new look. Rust in metal is a common form of oxidation. It occurs due to the interaction between the metal surface and environmental conditions. Rust gradually degrades a metal’s durability. Therefore, the laser cleaning method is widely practiced in many industries to eliminate this issue.

Traditional rust removal methods require lots of protective equipment and blasting equipment. However, the laser rust removal machine offers a more straightforward way. You don’t need any additional protection for the laser cleaning machine. It is a cost-effective and reliable rust removal method.

Application: Laser rust removal machine is prevalent in most repair workshops. Especially in the automotive sector, most repair shops require this technology. However, it is also popular in other mechanical workshops. However, in the food and medical industries, regular maintenance of the machine equipment is necessary. A laser rust removal machine plays a significant role in cleaning this equipment. As a result, the company can offer higher production and lower downtime. Moreover, laser cleaning machine is also famous for cleaning military weapons. Besides, cleaning outdoor walls, electronic components, aircraft repainting, etc., are noteworthy examples.

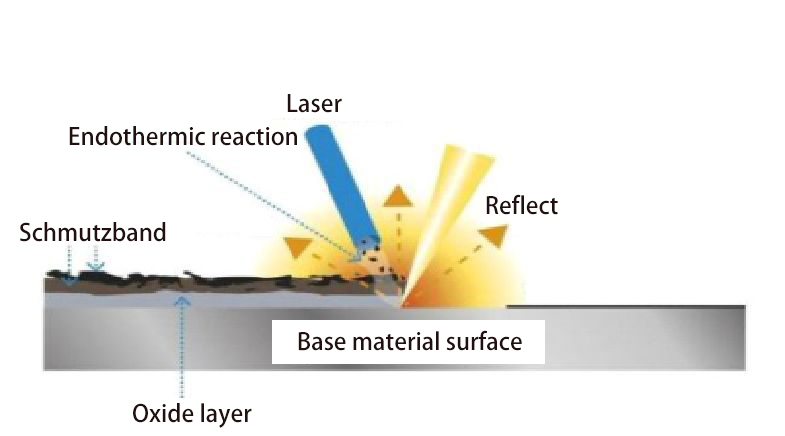

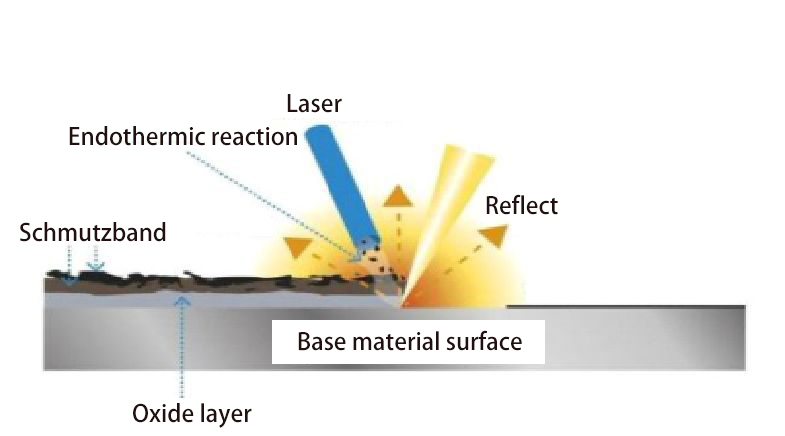

How does it work?

A laser rust removal machine produces powerful laser beams from the stimulation of lasing materials. These materials may include fiber, CO2, or UV. However, these laser beams travel through electrical discharges or lamps. Later the machine reflects the laser on amplifying mirrors to produce the required energy. When the laser beam hits the surface of the metal equipment, it usually breaks the bonds between the ablation layers and the metal surface. And then, the contaminants are removed from the surface and leave the metal, giving it a new look. It works on both regular and irregular surfaces. Therefore, you don’t need to worry about cleaning cylindrical objects.

Benefits of Laser rust removal machine

Laser rust removal machine is so popular because of their wide range of benefits. This technology can replace other traditional cleaning methods. In addition, it provides the most precise and better results than any other method for cleaning rust. The following are the most common benefits of the laser rust removal machine.

Safe and reliable

The laser cleaning or laser rust removal process is a non-contact process. Besides, it doesn’t require any chemical use for the operation. As a result, laser rust removal is completely safe and user-friendly. However, a laser rust removal machine has all the necessary protective equipment. In addition, many control buttons provide excellent user-friendly controlling features. As a result, it ensures safety and reliability.

No damage to the substrate

The laser rust removal machine doesn’t affect the primary substrate. In this case, the laser cleaning technology work directly against most contaminants on the metal surface. As a result, it doesn’t create any scratches or deep grooves on the metal surface. The working principle of the laser rust removal machine indicates no damage to the substrate.

Convenient control

A laser rust removal machine usually comes with lots of modern features. These features include a digital control display and emergency switches. These features make this machine more convenient and user-friendly.

Precision work

The laser beams are tiny as light particles. Every line and corner of the metal surface can not hide from this technology. However, the laser rust removal machine doesn’t require a consecutive operation to get the highest output. Therefore, laser cleaners provide excellent precision and satisfying result.

Versatile

The laser rust removal machine works on all types of metal surfaces. Besides, it can also work on other materials such as leather, plastics, wood, or acrylic. All regular, irregular, or cylindrical shapes are suitable for this laser machine.

Fast and cost-effective

A laser rust removal machine is incredibly faster than any other cleaning method. Since this laser machine doesn’t require consecutive operation, it promises a cost-effective way.

Environmentally Friendly

Laser rust removal is a green cleaning method. It doesn’t need any use of chemicals. However, the contaminants from the metal surface are a solid powder that is small in size and easy to store. In addition, this wastage doesn’t create any photochemical reaction or pollution. As a result, it is proved that the laser rust removal process is environmentally friendly.

How to choose the suitable laser rust removal machine

Selecting an ideal laser cleaner is not difficult. All you need to do is to understand some process and machine parameters. If you know all these parameters, you can easily make your decision. The following are the critical parameters that you should consider the most.

Laser Power and pulse frequency: Check whether the laser machine offers continuous or pulsed frequency. It is important to note that pulsed frequency is ideal for laser rust removal methods.

Laser safety: Ensure a class-1 safety enclosure before purchasing the laser machine. In the case of some handheld laser rust-removing devices, you may need additional protective PPE.

Cleaning speed and times: These two parameters can be determined from the capacity of the power range. High-power laser machines offer more efficiency and fast cleaning.

Fume extraction: The cleaning process usually creates waste material. They are supposed to extract from the working space. Fume extraction is one of the most commonly used techniques in this case.

Mobility features: You can find three features of a laser rust removal machine. They are a handheld laser cleaning machine, fixed laser cleaners, and a cabinet system. Therefore, before choosing the ideal laser cleaner, decide which type you require for your application.

After-sale service: One of the most important things you should demand from the producers is this. Most customers may experience issues operating their laser cleaning equipment after purchasing it. You may need professionals who can address your difficulties in certain circumstances.

Budget: The cost of laser cleaners is crucial when choosing appropriate equipment. The size, power, and technology of the cleaning laser machine generally determine the price of this machine.