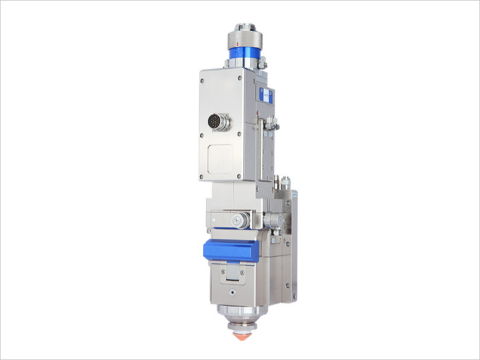

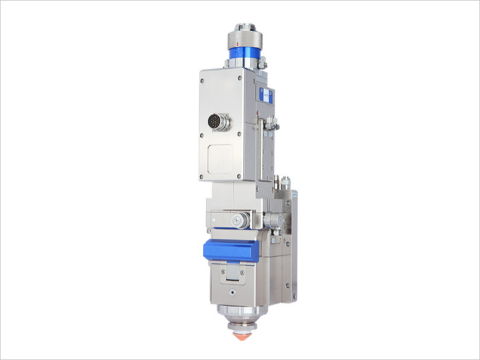

The laser head is characterized by high brightness, high energy and very high directionality. The beam expander, reflector, focusing mirror and other components are arranged between the light source and the workpiece, and finally the processing head. The laser beam is focused through the optical path system to a very small spot with very high energy density and reacts with the material by the processing method. All laser equipment, such as laser welding machines and laser cutting machines, share a high level of efficiency and precision. This is the main factor that can replace many conventional devices. However, because most equipment has external factors that work in relatively poor conditions in the factory and internal factors (such as its own attachment parameters) that work in the factory, it may not be fully effective in a given application.

The laser of fiber laser cutting machine has four main characteristics: high brightness, high directionality, high monochromaticity and high coherence.

1.Vapor cutting machine

When the substrate is heated by the high power high density laser beam of the laser cutting machine, the surface temperature of the material increases at an accelerated rate, which reduces the problem of material melting caused by heat conduction. As a result, some of the material in direct contact evaporates and disappears, and some of the material is blown away by the auxiliary gas.

2. Melting cutting machine

When the power density of the laser beam incident by the laser cutter reaches a certain value, the material in the beam irradiation point starts to evaporate, thus forming a hole. Once this small hole is formed, it will absorb the energy of the incident beam and turn into a black body. The hole is surrounded by molten metal walls, and then the airflow coaxial to the beam carries away the molten material around the hole. As the workpiece moves, the hole moves laterally in the cutting direction to form a slit. The laser beam of the laser cutter continues to shine along the slit and the molten material is continuously or pulsatingly blown away from the slit.

How much does a fiber laser cutting machine cost? How much is the weekly laser maintenance?

1) Check whether there is oil and water in the gas mixing unit of the laser, if there is, please clean it in time; check the laser gas drying filter. If more than 1/4 of the color changes to red or white, it needs to be replaced. Its normal color is blue.

2) Check whether there are impurities in the chiller filter.

3) Check whether there are impurities in the laser cooling water circuit.

4) Check the condensate level in the compressed air separator (located in the air source unit). Check the vacuum pump oil level (located below the air supply unit). When the pump is cold, the oil level at the centerline of the oil window should be between +5 mm-0 mm and 0 mm and refilled as necessary.

5) Check the oil level of the Roots pump. The oil level in the gearbox of the Roots pump can be seen through the oil window on the end face of the gearbox. With the pump off and at low temperature, the oil level at the center line of the glass should be between +5 mm and 0 mm. If necessary, add HTCL 2100 oil.

The main materials suitable for metal fiber laser cutting machines are titanium, titanium alloy, etc.

First of all, we need to figure out that fiber laser cutting machine belongs to the category of metal cutting machine, so it can only be used for processing metals and not for processing non-metallic materials, such as stone, glass and other materials. The reason is that the wavelength range of fiber laser cutting machine is not in the absorption range of such materials or not suitable for absorption to reach the ideal range.

Secondly, fiber laser cutting machine cannot cut density board.

Fiber laser cutting machine is a heat treatment. Cutting density board will cause burning, and the cutting edge will burn and can not meet the cutting requirements. This material is mainly raw material of fiberboard, wood fiber, plant fiber, some of which are made of urea-formaldehyde resin, synthetic board and other materials with adhesives. These types of materials fall into the category of density board and cannot currently be processed by fiber laser cutting machines. Over the past few years, many home laser cutting machines have been pursuing breakthroughs and competition in increasing their power levels. Those with the highest power levels seem to be the best, and those with the highest technology and product quality are the highest. In reality, this idea is one-sided.

Today, as laser cutting machines become more widely used, the needs of users dictate the development and production of products, as users not only evaluate which company produces higher power laser cutting machines, but also look at the actual results. produced by your laser cutting machine. In other words, if a customer can use a 500W fiber laser cutting machine to cut high quality workpieces, but the results are not satisfactory with a 1000W, then a 1000W fiber laser cutting machine is meaningless to the customer.

How much does a fiber laser cutting machine cost?

Laser cutting machine is an important equipment for flexible production. The flexible processing of fiber laser cutting machine means variable processing combination: the laser beam is guided directly. The laser can be rotated, tilted, moved up and down, and can process vertical surfaces of the workpiece and other complex workpiece surfaces. The direct drive has no idle range and is highly accurate.