The laser is another major invention of the twentieth century after nuclear energy, semiconductors and computers, and is widely used in industrial manufacturing, biomedical and military fields by virtue of its good monochromaticity, directionality and brightness. It is known as the "fastest knife", "the most accurate ruler" and "the brightest light"

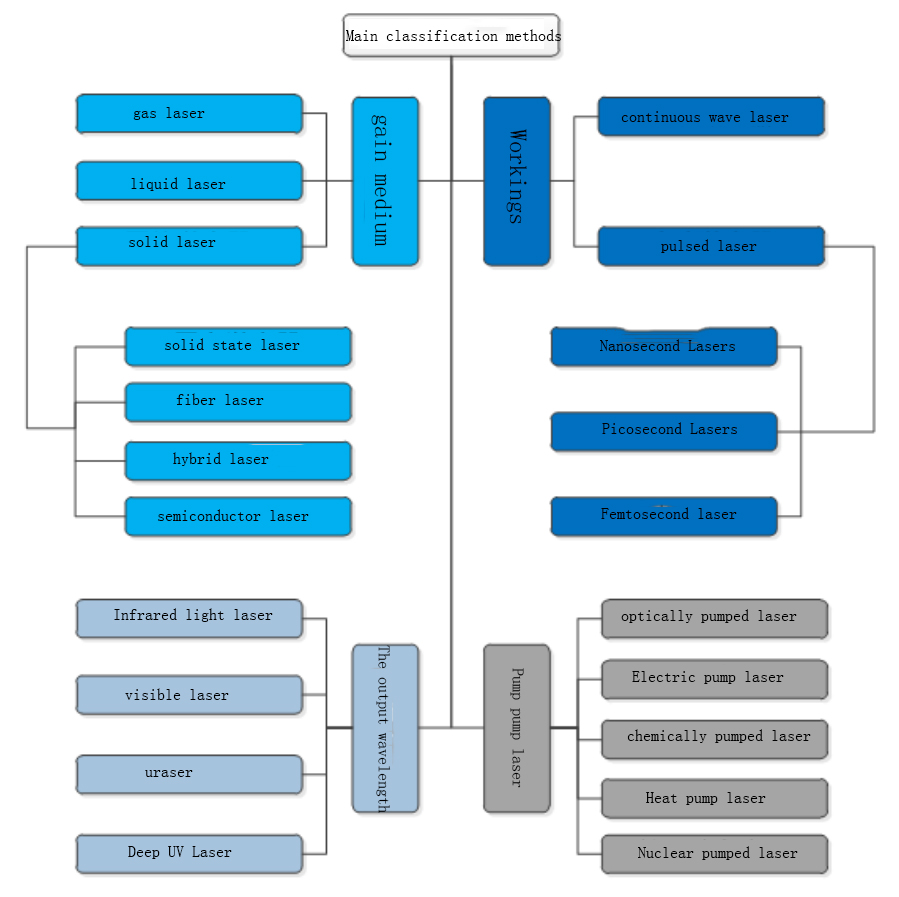

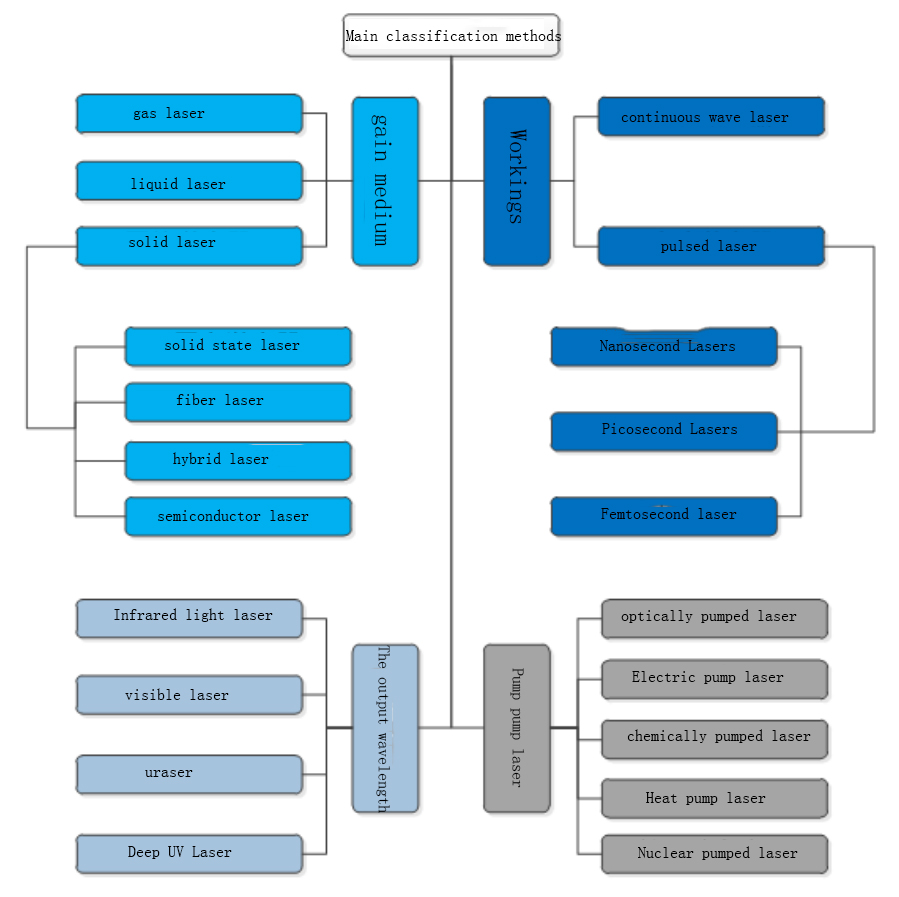

Lasers can be classified according to gain medium, output wavelength, mode of operation and pump mode, as follows.

1 Classification by gain medium

According to the different gain media, lasers can be classified into solid (including all-solid, fibre, hybrid, semiconductor), gas and liquid lasers, etc. Solid lasers in a narrow sense generally refer to all-solid lasers. The company's products currently cover all-solid-state (DPSS), MOPA fiber (polarization) and solid-state fiber hybrid mode lasers and other mainstream lasers.

There are nearly a thousand types of gain media available, including neodymium-doped yttrium aluminium garnet (also known as YAG), ruby, neodymium glass, optical fibres and carbon dioxide. Each type of gain medium laser has its own comparative advantages, the application area has some focus, the possibility of complete replacement between each other is small.

2 Classification by output wavelength

Lasers can be classified according to wavelength as infrared lasers, visible lasers, ultraviolet lasers, deep ultraviolet lasers and so on. The wavelength range of light absorbed by different structured materials varies, so lasers of various wavelengths are needed for fine processing of different materials. Infrared lasers and UV lasers are the two most widely used lasers: infrared lasers are mainly used in "thermal processing", where the material on the surface of the material is heated and vaporised (evaporated) to remove the material; in thin film non-metallic material processing, semiconductor wafer cutting, organic glass cutting, drilling, marking, etc., the high energy UV photons directly destroy the molecular bonds on the surface of non-metallic materials, causing the molecules to break away from the object, which does not produce a high heat reaction, and is therefore often referred to as "cold processing".

Lasers can be classified according to wavelength as infrared lasers, visible lasers, ultraviolet lasers, deep ultraviolet lasers and so on. The wavelength range of light absorbed by different structured materials varies, so lasers of various wavelengths are needed for fine processing of different materials. Infrared lasers and UV lasers are the two most widely used lasers: infrared lasers are mainly used in "thermal processing", where the material on the surface of the material is heated and vaporised (evaporated) to remove the material; in thin film non-metallic material processing, semiconductor wafer cutting, organic glass cutting, drilling, marking, etc., the high energy UV photons directly destroy the molecular bonds on the surface of non-metallic materials, causing the molecules to break away from the object, which does not produce a high heat reaction, and is therefore often referred to as "cold processing".

3 Classification by mode of operation

Laser operation is the core of laser technology and can be divided into continuous lasers and pulsed lasers.

Continuous lasers have a stable distribution of the number of particles at each energy level and the radiation field in the cavity, and are characterised by the excitation of the working material and the corresponding laser output in a continuous manner over a long period of time. Continuous lasers provide continuous laser output over a long period of time, but the thermal effects are more pronounced.

Pulsed lasers output laser light in a discontinuous manner and are mainly characterised by low thermal effects and good controllability.

The pulse width of a pulsed laser refers to the time that the laser power lasts when maintained at a certain value. Currently commonly used industrial micromachining lasers can be divided into nanosecond lasers, picosecond lasers and femtosecond lasers. The narrower the pulse width, the higher the requirements for the application of laser modulation technology.

A. Nanosecond (10-9s) lasers: The pulse duration of a nanosecond laser is generally in the range of a few tens to a few hundred nanoseconds. Nanosecond pulsed laser technology is currently more mature on the market, with a wide range of products to choose from. Fiber lasers and solid state lasers each have their own advantages in the development process towards high power and short wavelengths.

B. Ultrafast lasers: Ultrafast lasers arelasers with shorter laser pulse durations. Compared to nanosecond lasers, ultrafast lasers have a very short pulse duration, extremely high instantaneous power, focused energy to a very small spatial area and are not affected by the pulse repetition frequency and average power, the beam quality is constantly stable. At present, ultrafast lasers mainly include picosecond (10^-12s) lasers and femtosecond (10^-15s) lasers, and ultrafast pulsed laser technology represented by femtosecond lasers is one of the world's leading laser technologies.

The above classification methods show that solid-state lasers (i.e. the above-mentioned all-solid-state lasers) and fibre lasers are the two mainstream lasers on the market today, with major differences in the main application scenarios and technology development trends, and that the two technology lines are developing side by side without any mutual substitution.

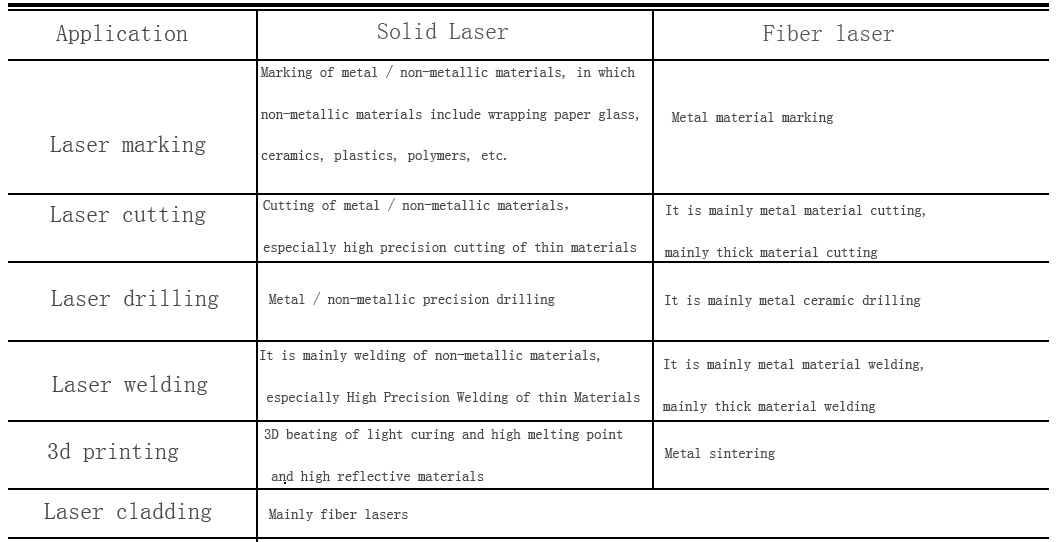

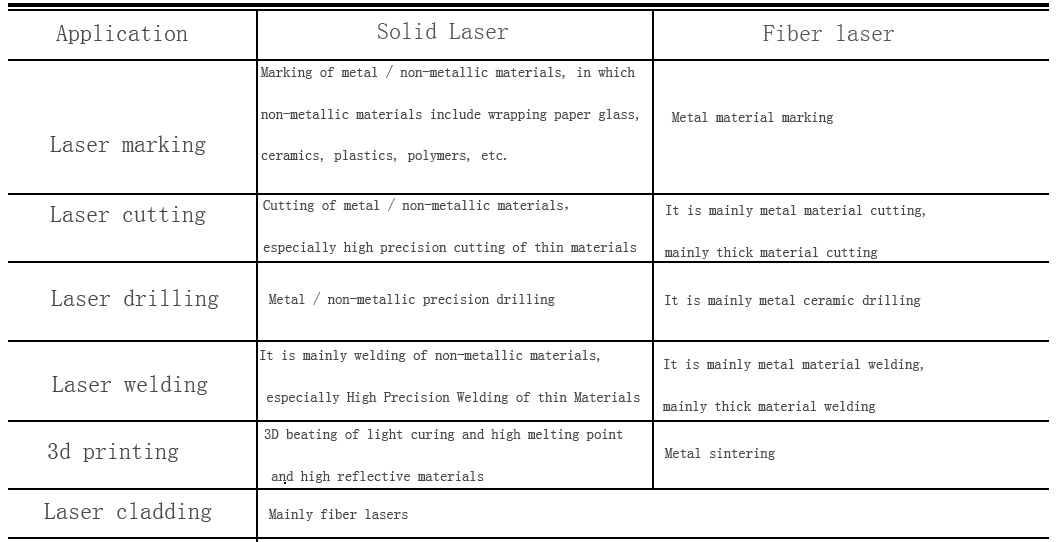

The differences in the application of solid-state lasers and fibre lasers in the main laser processing applications are as follows.

From the above table, both solid-state lasers and fibre lasers can be used in major laser processing areas such as marking, cutting, drilling, welding and additive manufacturing, but there are differences in the specific application scenarios in each segment, as follows.

①Macro processing area

This field mainly uses fibre lasers and generally does not use solid-state lasers. Fibre lasers include continuous fibre lasers and pulsed fibre lasers. Due to the high average power of continuous fibre lasers, they can be widely used for macro processing such as cutting and welding of thick metal materials. Macro processing is currently a large market, and the main products of comparable companies in the same industry are continuous fibre lasers, such as Rike Laser and Chuangxin Laser.

②Micro-processing field

This field mainly uses solid-state lasers, with some scenarios using pulsed fiber lasers. Solid-state lasers can convert infrared light into short wavelength laser light such as green light, ultraviolet light and deep ultraviolet light through frequency doubling crystals in the resonant cavity and output to the outside world, and shorter wavelengths are the development trend of micro processing lasers, which produce lower thermal effects and high energy utilization efficiency, thus effectively improving processing accuracy and realizing ultra-precise and ultra-micro processing. With its short wavelength (UV, deep UV), short pulse width (picosecond, nanosecond) and high peak power, solid-state lasers are mainly used in the field of precision micromachining of thin, brittle and other metallic and non-metallic materials, in addition, solid-state lasers are widely used in cutting-edge scientific research in the environment, medical and military fields, with a broad development prospect.

Pulsed fibre lasers can be used in the field of micromachining, as its wavelength is mainly limited to the infrared range, so it is generally used in metal materials and has a certain thickness, relatively low precision requirements of some micromachining field.