Introduction

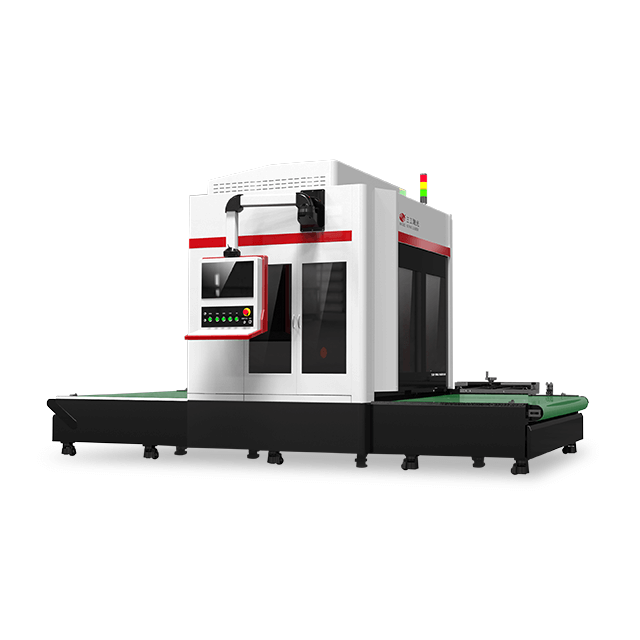

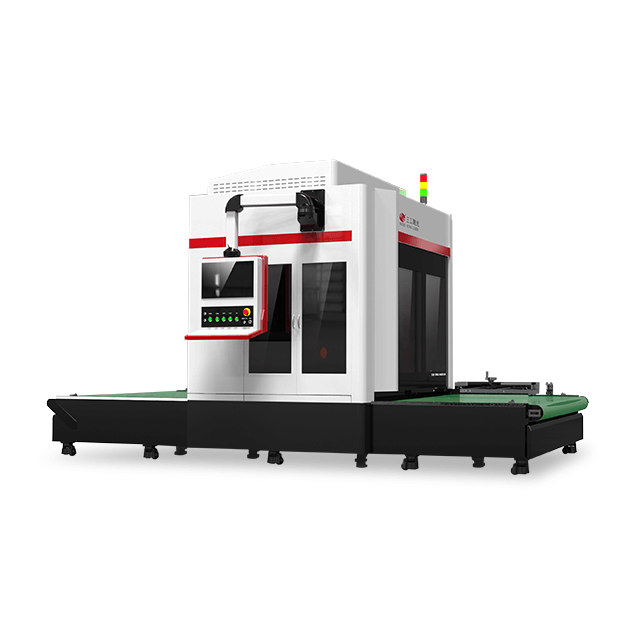

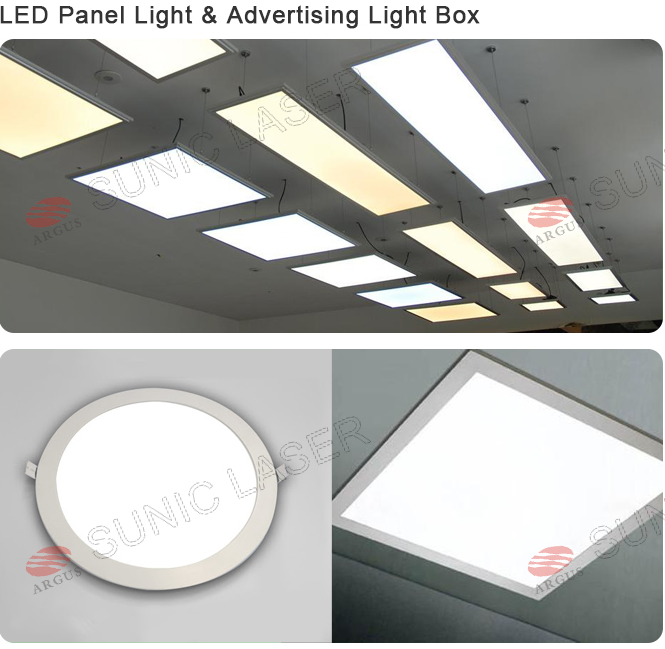

The SCM3000 LGP Laser Dotting Machine is specialized designed for LGP Laser Dotting Application, which is widely used in the LED panel light producing, and it is also the most popular model in the market. It is the outcomes of SUNIC Laser’s technical expertise and experience in marking and engraving PMMA sheets for Backlight applications exploiting proprietary laser technology to produce micro- points by light guide plate (LGP) on PMMA panels up to 1500×1500 mm working size. This process is much more productive in comparison to other traditional technologies and other lasers, even with the maximum quality.

Machine Structure

CO2 Dynamic Laser Marking Machine SCM3000 main structures:

Imported laser tube

High speed galvo scanner

Sunic Laser self-developed linear 3D Dynamic Focusing System

Device control system

Self-developed Control software

The high precision thermostatic water cooling system.

The host machine is as follow:

Machine’s Control section is focused on the Electrical main control section. The whole machine’s optical components are focused on the optical main beam and inside the square head through the complete optical design. The integrated water chiller provides a circulation water cooling system for the machine during working. CO2 Dynamic Laser Marking Machine mainly includes the following parts:

Technical Parameter

Model | SCM3000 |

Max working Area | 1500*1500mm |

Laser power | 250 watts/350watts |

Power Consumption | ≤ 7kWh |

Life Span | Over 20000 hours |

Marking Speed | ≤10000mm/s |

Worktable | Marble worktable |

Laser Source | US Coherent Diamond J Series Laser Tube |

Laser Wavelength | 10.64μm |

Laser Frequency | 20kHz~200kHz |

Focusing method | 3D dynamic focusing system |

System Support | Windows |

Output Compatibility | Auto CAD, Photoshop, CorelDRAW etc |

File Formats | PLT, DXP, BMP, JPG, AI etc |

Software Character | Integrated Function of Dotting Design, Vector Drawing, Marking, Scribing and Cutting |

Power Supply | 110V~380V/50Hz~60Hz |

Cooling Way | Circulation of Water Cooling |

Features

The Light guiding plate processed by Laser dotting display the excellent features of super thinner&brighter, uniform light guiding, energy saving and green, no dark areas, longtime lasting, no yellowing, convenient and easy maintenance:

1, Thinner acrylic materials are viable, to save raw cost

2, Higher lighting efficiency

3, Both dots and marking lines are generated by reasonable arrangement (sparse in edges and intensive in middle ) processed by professional optical designing software, to maximize the uniformity of lighting efficiency of at least 90%.

4, Longtime lasting, and no yellowing features to ensure an indoor lifetime of 8 years’ normal use

5, No affects by water or humidity, while by which the LGP processed by screen printing can be easily affected and bleak.

6, Simple process as well as higher flexibility with LGP production. It’s supportive with various LGP shapes according to customers’ designs. Faster marking, lower cost, and avoid the shortcomings of complexity processing, poor durability in screen printing craft.

7, Much Lower requirement with plate flatness. The laser dotting machine is capable to bear a deviation of 5mm in flatness with few affect, which is totally unacceptable in screen printing industry.

Packaging

Size:1000(L)*800(W)*600(D)

Gross Weight:400KG

Packaging Details:Standard Crate for export. Whole machine will be covered with film before packing.

Cooperation Partner: