|

Field of Application

In recent years, with the continuous maturity and popularization of laser technology, laser welding technology has been widely used. The emergence of new lasers and the continuous improvement of laser technology have made the laser welding technology improve in welding speed, quality and efficiency. At the same time, laser welding technology has also begun to expand to the field of microfine and fine welding, such as the packaging of microelectronic devices, the manufacture of miniature sensors and so on.

Laser welding applications:

1)Sanitary ware industry: water pipe joints, tees, valves, shower welding, etc.

2)Hardware industry: impeller, kettle, handle and other complex stamping parts, casting welding, etc.

3)Electronic industry: electronic devices, batteries, sensors and other components, etc.

4)Eyewear industry: precision welding of eyeglass clasps and frames made of stainless steel, titanium alloy and other materials.

5)Automotive industry: engine head gasket, hydraulic tappet seal welding, spark plug welding, filter welding, etc.

6)Aerospace industry: high-temperature alloy blades, aircraft engines, missile components, satellite components, etc.

7)Industrial manufacturing: steel structures, pipelines, pressure vessels, oil equipment and other components

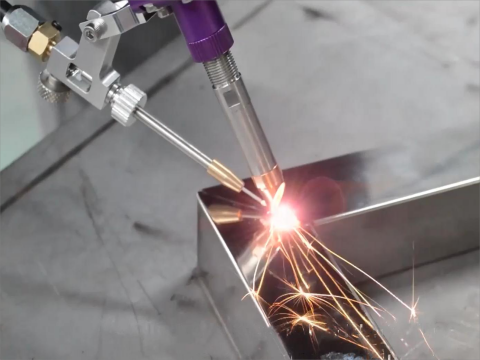

| Product Process by ARGUS Laser

Plumbing Laser Welding

Plumbing Laser Welding  Door Frame Laser Welding

Door Frame Laser Welding  Stainless Steel Box Laser Welding

Stainless Steel Box Laser Welding

Would you like more information about laser welding machine?

Click the link below for more information

| Optional Laser Welding Machine Type

Portable Fiber Laser Welding Machine

Portable Fiber Laser Welding Machine

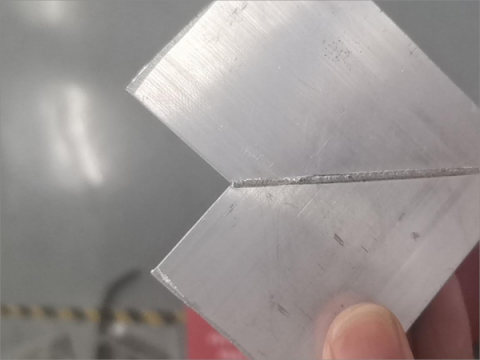

1) Fast welding speed, 4~6 times faster than traditional TIG/MIG welding.

2) Very simple for Novices to weld at a professional level .

3) Welding joint are Smooth & Beautiful. Almost no need polishing, save time.

4) Higher strength during Tensile test.

5) Low labor cost, reduce 50% cost compare MIG.

6) No Radiation, Safety for welder.

Robot Arm Fiber Laser Welder

1) Highly flexible robot arm, large surface welding advantage, high welding efficiency;

2) Non-contact welding, robotic arm highly flexible, can carry out any welding action;

3) Can be three-dimensional welding, not limited to plane welding;

4) The arm use of large size welding range, in the welding production line has a great advantage;

Fully Automatic Platform Laser Welding Machine

1) Only localized heating of the connection part, no thermal effect on the component body;

2) Fast heating and cooling speed, fine joint organization and high reliability;

3) Non-contact joint heating;

4) Real-time quality control is possible, etc.