Fiber laser engraver technology is a monolithic, fiber to fiber, a compact solid-state configuration that cuts flat metal. This is the main advantage. Fiber laser has lower operating costs than comparable CO2 lasers. The characteristics of the fiber laser beam provide faster cutting speeds than the CO2. Fiber laser cutting systems are capable of cutting more than one inch using a higher power fiber laser and even faster when nitrogen was used as an auxiliary gas.

However, the best place to achieve the greatest advantage over CO2 systems is the 1/2-inch and below range. It is clear that fiber laser technology is the most efficient and cost-effective way to work with stainless steel, copper, aluminum, brass, or copper. If you are cutting wood, acrylic, or leather, this technology is also available. It is recommended that you use a CO2 laser.

Advantages CO2 lasers

1.Surface finish: CO2 lasers typically produce better edge quality on stainless steel and aluminum workplaces.

2.Flexibility: CO2 lasers offer flexibility for a range of laser applications, including non-metals.

3.Known technology: Because CO2 laser technology has been around for more than 30 years, the results are completely predictable.This provides a good level of assurance for the user.

Disadvantages CO2 lasers

1.Operating expenses: The CO2 laser cost of mirrors, bellows, and laser gas required to maintain the beam path delivery system clean and pure is 70% more than the power consumed by CO2 resonators and blowers.

2.Maintenance: The beam path delivery system requires maintenance. This is disruptive for manufacturing and very expensive.

3.Speed: CO2 lasers are not able to compete with fiber optics in thin materials. For example, the recommended cut speed for a 4KW CO2 in 16 GA mild steel using N2 as the cutting gas is only 260 IPM, compared to about 1,417 IPM for the same equipped fiber laser, a significant difference.

Advantage Fiber Laser

1.Investment Cost: The price of solid-state laser technology is falling as it becomes more popular. Fully equipped domestic fiber laser cutting machines can be bought starting at $300K

2.Maintenance: The absence of beam path delivery systems and their extensive use of mirrors, bellows, and gas-wetted fiber lasers (especially the solid-state resonator types) greatly reduces the amount of maintenance required and the costs associated with maintenance.

3.Speed: In the competition between fiber lasers and CO2 lasers for thin materials, there is simply no comparison. Fibers are twice to three times faster than gauge materials.

4.Operating costs: Fiber lasers require about 1/3 the power consumption of their CO2 counterparts due to the lower power requirements and cooling requirements of the resonators. This, along with faster cutting and less maintenance, makes fiber lasers very cost-effective.

Disadvantages Fiber Lasers

1.Treatment of thick materials: The advantage of CO2 lasers for surface treatment is their ability to treat thicker materials, such as stainless steel and aluminum. Although fiber laser technology may be a distant future, CO2 remains the market leader in the field.

2.Overall flexibility: The CO2 Laser is more flexible than other lasers, and can cut a greater variety of materials, particularly non-metals. Fiber-optic technologies can cut brass and copper straight out of the box (CO2 Lasers had great difficulty with these materials), but they are still limited in their use, particularly for non-metallic applications.

3.Technology/comfort level: If there are CO2 laser systems at your facility, it is possible that you initially see this technology as the “devil you know” and not the “devil you don’t.”

What Materials Can CO2 Lasers and Fiber Lasers Cut?

A Fiber laser is simply the term for the fiber optic delivery system that delivers an intense and amplified beam of light

to the cutting head on a laser machine. This term doesn’t describe the process of creating the light source (which is different than a CO2 resonance). Fiber optic beam delivery has made manufacturing lasers much easier and many machines are now available at very low prices.

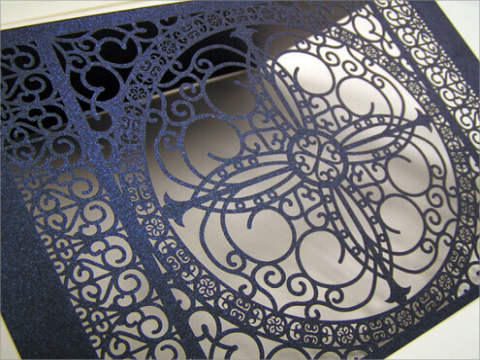

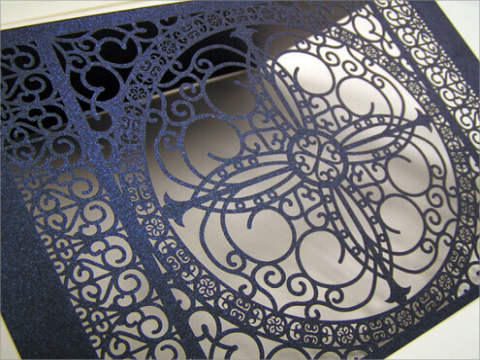

CO2 lasers engraving products

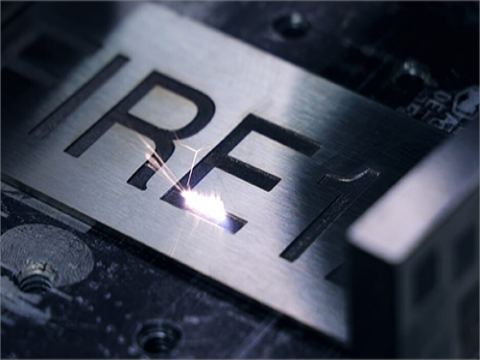

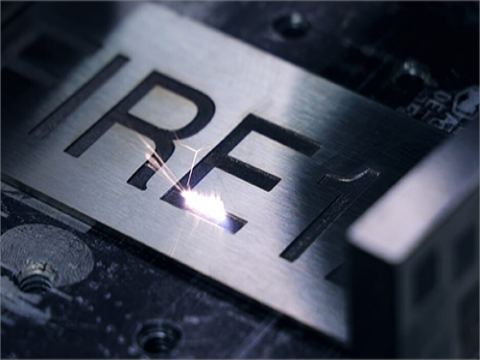

Fiber lasers engraving products

The advantage of CO2 lasers is that they can work with a wide range of materials. They can use with organic materials (non-metals). Organic materials are things like wood, acrylic, plastic, rubber, leather, and anything like that. Fiber lasers are mainly used with metals.

However, CO2 lasers cannot use with a variety of metals. That’s because some metals are by nature highly reflective. By reflective nature, I mean that these metals are able to reflect (reflex) light/laser. It’s like pointing a flashlight at a mirror and the light will reflect back at you. Metals such as aluminum, copper, gold, brass, and silver are highly reflective. If the light is reflected back into a laser machine, it can damage it and CO2 laser cost thousands of dollars to fix! So make sure you triple check that the laser machine you buy can work with the material you need without causing any damage. CO2 laser machines have a laser beam that is easily reflected back by highly reflective metals. Fiber lasers have a much lower frequency laser beam.

(In fact, almost all metals are by nature reflective. It’s just that some metals are more reflective than others.)

The shorter wavelengths of fiber lasers may work well with a variety of metals, but not with organic/non-metallic materials. CO2 machines can also use on organic materials like wood and plastic. A fiber laser engraver can cause a fire if it does use on wood. If it is to use on plastic, it can melt it.

A CO2 laser can work with metal as long as it has enough power (watts). You need about 25-150 watts to engrave something like steel and about 300 watts to cut it. CO2 lasers also need to use oxygen as a carrier to cut these metals. Note that it takes less power (wattage) to engrave/mark material than it does to cut it.

Calculating the total cost of ownership

Typically, the overall cost of a CO2 laser is higher than that of a fiber laser over time. Here are some things to consider when calculating the total cost of a laser.

Consumables: CO2 lasers require a gas (such as oxygen or nitrogen) to operate, whereas fiber lasers do not. (Fiber lasers can use gas for better cut quality).

Power Consumption: Fiber laser cutters consume about three times as much energy as CO2 lasers. This basically means that the fiber laser uses 3 times less power to cut the same thing.

Parts maintenance/cleaning: CO2 lasers have parts such as mirrors, turbines and water tanks that need to be cleaned and repaired. If not, they can break down and cost you money in repairs. Therefore, make sure you remember to pay attention to the needs of your laser machine. It can save you a lot of money in the long run.

Repair: CO2 laser parts are more likely to fail than fiber laser parts. It is estimated that it takes about 50,000 to 100,000 hours for a fiber laser machine to fail, while CO2 takes about 20,000 hours. Fiber laser cutters are what you would call solid-state machines (almost all in one piece). This means that they have no moving parts. Therefore, the likelihood of failure or non-functional operation is much lower.

Lifespan: Every machine will eventually break down …… Generally speaking, high-end CO2 laser machines last about 10-15 years. Fibers can last twice as long if not more than three times as long.

Remember to keep these points in mind when trying to calculate the cost of the type of laser machine you will choose. If you don’t cut materials often and need to cut non-metallic materials such as wood or acrylic, then a CO2 machine would be your best choice. If you need to cut a lot of metal, especially thin metal, then a fiber laser may be the best choice for you.

Another thing to remember that will work in your laser machine. That’s time. You know what they say, time is money. How fast your laser machine operates can make a huge difference in the value of your investment.

Cutting Speed – How fast is your laser cutting?

Fiber laser engraver are significantly faster than CO2 lasers in cutting thin sheets (< 8 mm), especially when cutting stainless steel. For 1 mm, fiber lasers can cut up to 6 times faster than CO 2 lasers. For 5 mm paper, the difference is reduced to about 2 times.

The cutting speed of thin sheets can increase by 2-3 times by increasing the power of the laser source to 2kW. The CO2 laser can cut thin sheets at a faster rate than the fiber laser. This is possible for the same laser power. The speed advantage is smaller than for sheets that are thinner.

Cutting quality – How smooth do you want your edges to be?

One of the advantages of CO2 lasers for cutting is that their cutting edge quality (sharpness/finer edges) is consistent across the entire thickness range of the material. This means that you don’t need to worry about your edges looking bad when cutting thin or thick material. The fiber laser becomes less efficient at making consistent cuts as the material becomes thicker.

Keep in mind that fiber laser engravers are getting better as time goes on. Today, the quality of cuts in thickness is not as bad as it was in the early days of fiber lasers. If you really want to get into fiber laser cutters but are concerned about cut quality, you should have the company you buy from the show you a demo. At Morphy, that’s what we do. Anyone local, we’ll let them walk in so we can cut out the samples they might need. Our customers can be confident that their machines will cut the product they require.

Points to consider when purchasing a CO2 VS Fiber Laser machine.

Based on data I found online, the average price of a 4kW laser cutter costs $12.73/hr CO2 laser per day. The average cost of a 4kW fiber laser cutter is $6.24/hr.

The main uses of fiber laser machines are cutting thin metals (0-5mm) and marking, engraving, annealing, etching, and even welding metals.

CO2 lasers can use cut, mark, and engrave a wide range of non-metallic materials such as plastics, textiles, and stones.

Fiber laser machines take up less space than CO2 laser machines. co 2 laser machines require gas tanks, pumps and piping. In contrast, fiber optic machines are much more compact.

Conclusion - So ...... which one should you buy?

What kind of laser should you buy? CO2 or fiber? It all depends on your business needs.

If you are cutting/engraving organic or non-metallic materials, then of course you will be looking for a CO2 laser cutter.

If the majority of your production deals with thin metals, you may want to consider investing in a fiber laser machine. With a fiber laser machine, your production will be faster and the overtime costs will not be as high as with a CO2 laser machine.