Black Marking on Aluminum

Anodized aluminum can be marked quickly and well with a laser. The anodized layer is extracted to produce a white marking.

These white marking in natural anodized aluminum are however not clearly visible. Black markings are therefore of significantly higher quality.

In this case, a MOPA laser is used in natural anodized aluminum to very nicely laser mark different tones of grey up to a rich black.

A MOPA (Master Oscillator Power Amplifier) laser is one that consists of a master laser, also referred to as seed laser, and a laser amplifier, put together to boost the output power.

An application of this process is marking high end smartphones, tablets and laptops, among others.The most famous application is Iphone,Ipad case black marking.

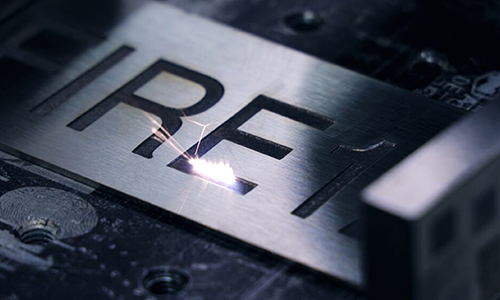

Color Marking On Metal

Metals such as stainless steel, titanium, chrome plate and transition metals are known to be good materials for color marking. But not all metals can be color marked, the marking color depends on material.

Factors such as material grade, material thickness and surface finishes can have an impact on the marking process.

Polished surfaces are more consistent in terms of color whereas brushed surfaces are more difficult to color-mark.

The MOPA laser is more suitable mark colors but it can only can control colors on stainless steel and not any other material.

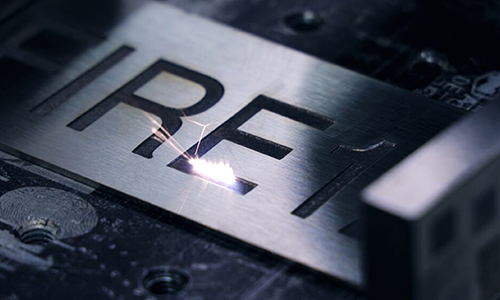

Black Marking on Metal

Fiber Lasers can be used to make black anneal marks on metals such as stainless steel.

An anneal mark is created by intensifying the oxide layer on the surface. This oxide layer is created on ferrous metals, such as iron, steel and high-grade steel, and titanium through localized heating.

Generally, the oxide layer is black.