Technical Parameters

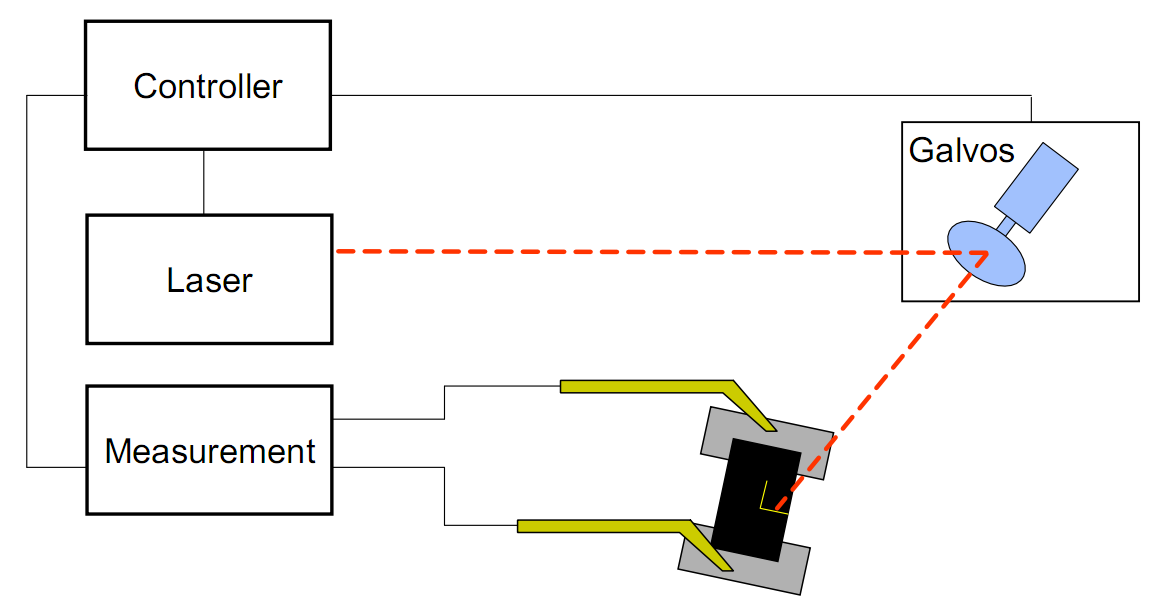

1.Laser System

l Laser Wavelength:1064nm

l Laser Average Power:10W(TEM00)

l Classical Spot Size: 35-50µm

l Focusing Method: Controlled by PC program

2.Laser Beam Locating System

l Laser beam Motion Range:60mm X 60mm

l Motion Resolution:5µm

l Repeated Positioning Precision:1µm

l Max. Scanning Speed:5000mm/s

3.Graphic Monitor System

l Monitor Mode:Laser Coaxial Monitor

l Proprietary technology: achromatic technology, wide laser, coincidence imaging

l Monitoring field:4-6mm(diagonal)

l Lighting source: LED lighting

4.Measurement System

l Resistor measure method:Current measurement method

l Measurement Range: 1Ω-10MΩ(16bit Resolution)

l Measurement accuracy.

0.1Ω< Rx < 100Ω ±0.05% + 0.5% / Rx

100Ω< Rx < 100KΩ ±0.05%

100KΩ< Rx < 100MΩ ±0.05% + 0.05% * Rx

l Measurement Speed:25µs

l Resolution of DC voltage:0.16µV(Full Scale of 10mV)

l Probe Card:42 lines, arbitrarily defined

l Motion of Probe Card:Computer Program Control

5.Computer & Software System

l Control Computer Dual Processor,19 Inch LCD

l Operation System:Windows XP

6.Step Repeated Motion System

l Motion Method:Precision screw and double linear guide

l Motion Range:300mm*300mm

l Max Ceramic Plane Size:150mm*150mm

l Motion Resolution:1µm

l Repeated Positioning Precision:±5µm

l Position Precision: ±50µm

l Max Speed:120mm/s(carrying idler)

7.Other technical indicators

l External control: standard 4-way program-controlled switch, expandable

l Cooling system:Air-cooling

l Supply voltage:220V AC Pressure:<0.4MPa Total power consumption:2500W