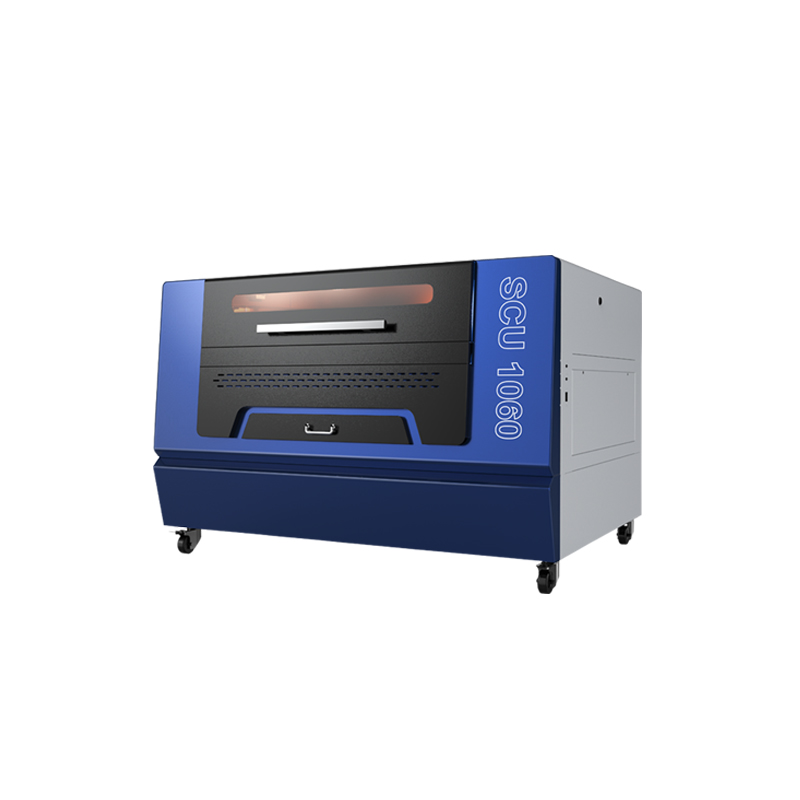

Automatic Paper Industry Processing

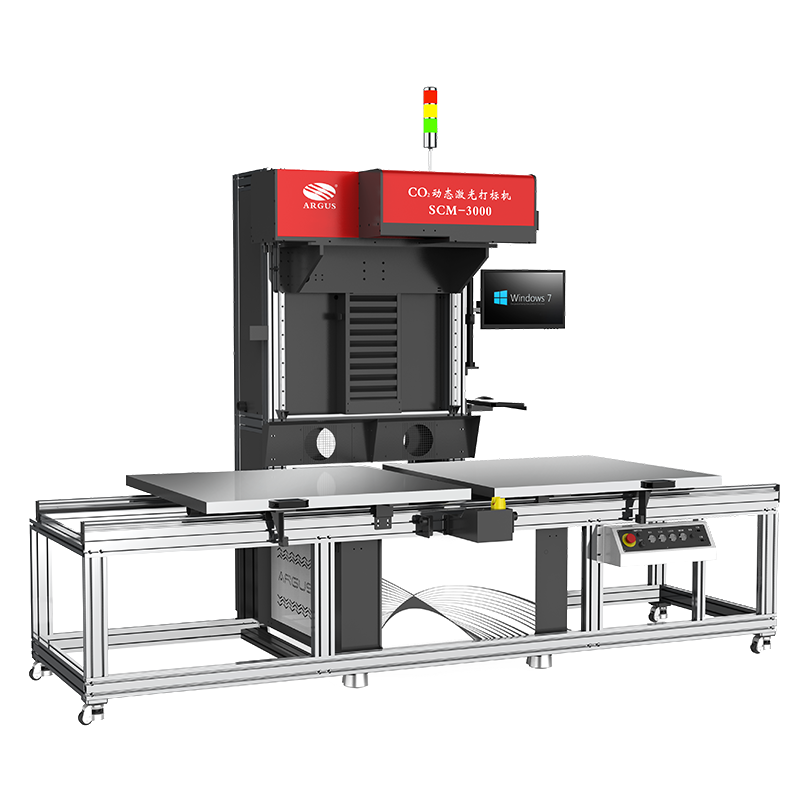

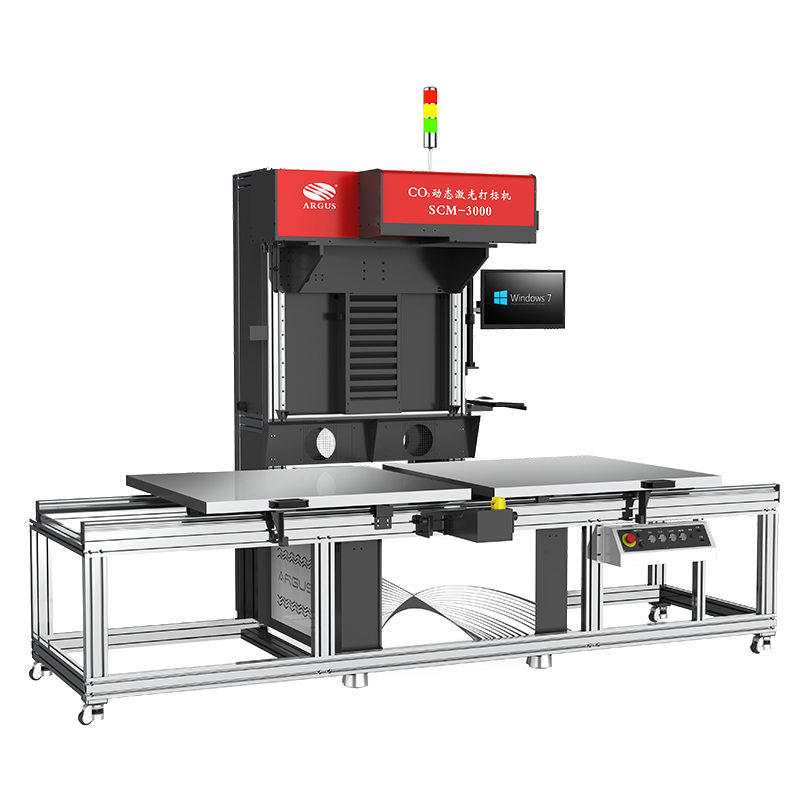

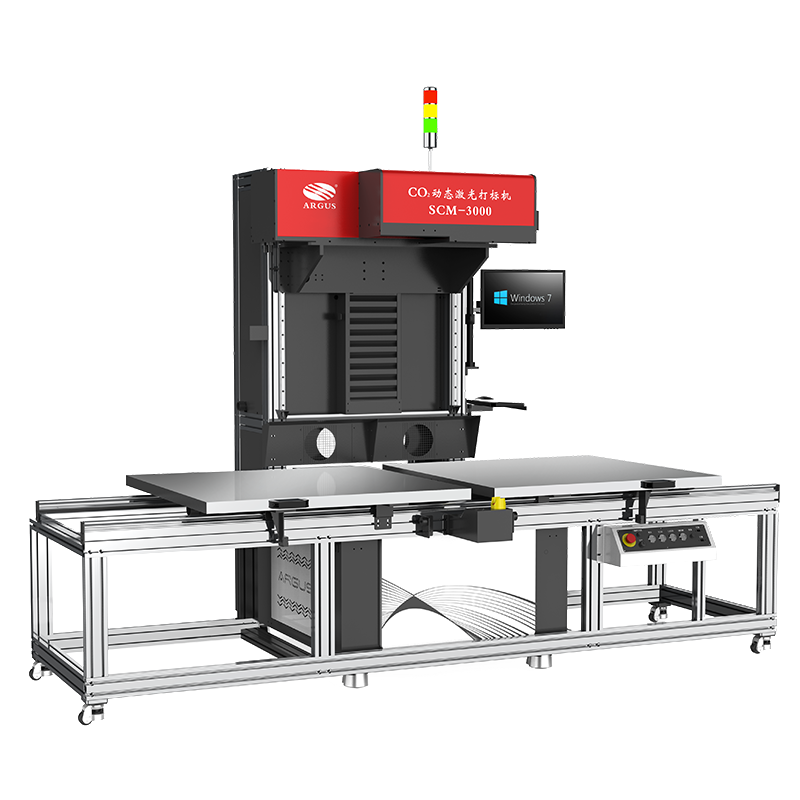

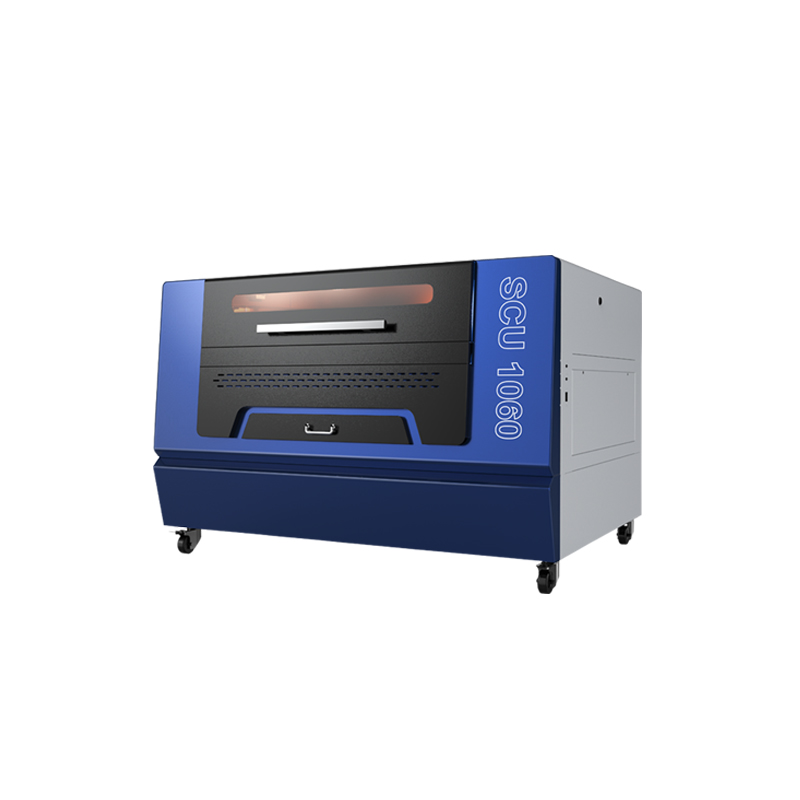

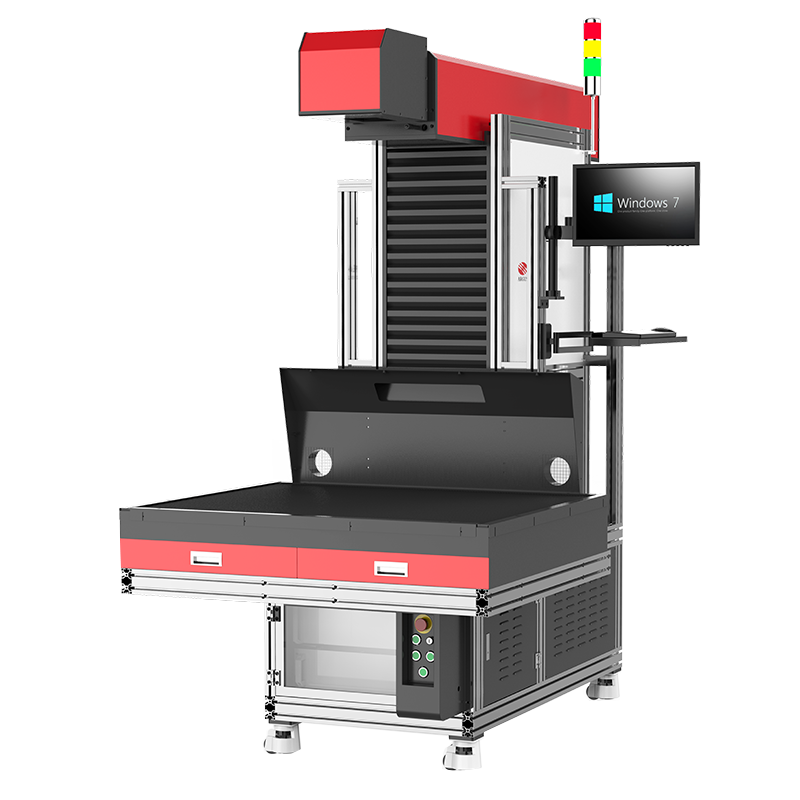

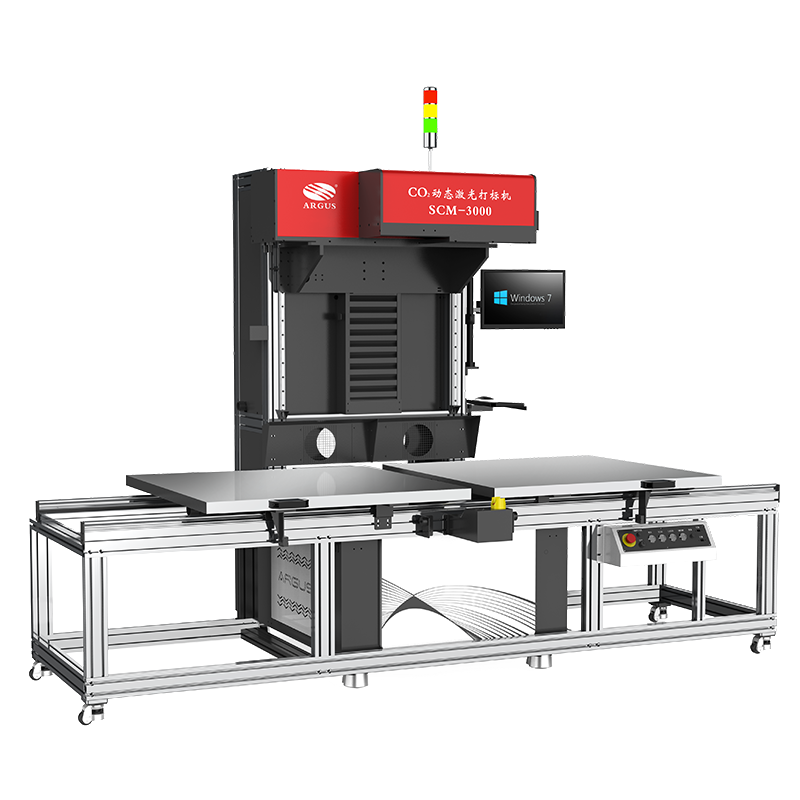

Argus Dynamic Laser Marking Machine

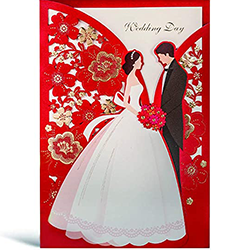

Exclusively Designed For Wedding Invitation Cards

|

|

|

|

|

|

|

|

|

|

|

|

|

|  |  |  |

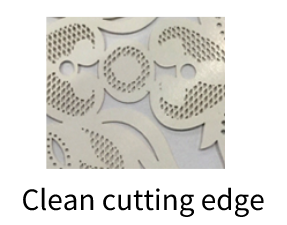

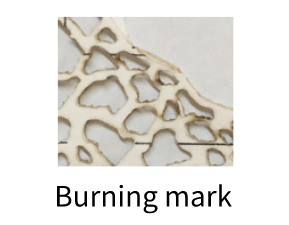

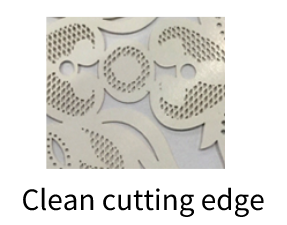

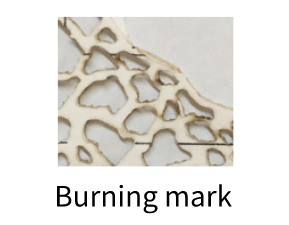

More refined cutting effects | No yellow no burnt edges | Marking area adjustable ( Max:800*800mm | Optional vision positioning system |

| Product Description

|Advantage of CO2 Dynamic Laser Marking Machine

1. Permanent

Mark will not subside because of environmental reasons(touch, acidic or reducing gas, high or low temperature etc).

2. Non-contact

Laser marking is a non-mechanical “light knife” for processing, the workpiece will not produce stress after marking. The working surface will not produce corrosion, no “tool” worn, non-toxic, non-polluting.

3. Wide application

CO2 Dynamic Laser Marking can work on all non-metal materials(Textile, Leather, PMMA, Wood, MDF, Paper, Marble, Glass etc.)

4. High precision for engraving&marking

CO2 Dynamic Laser Marking Machine can engrave fine pattern, the minimum line width can reach to 0.04mm. Engraving&Marking result is clear, durable and beautiful.

5. Low operating costs

Low energy consumption, no consumptive materials, and therefore lower operating costs.

6. High efficiency

CO2 Dynamic Laser Marking Machine’s Engraving&Marking speed can reach to 7000m/s, three times than that of traditional laser marking machine, marking process can be completed in seconds.

7. Large marking area

With the high power laser tube and the 3D Scanner technology, the CO2 Dynamic Laser Marking Machine can work on large size materials such as the clothes processing, leather processing, LGP(Light Guide Plate for LED Panel Light and TV) processing.

8. Easy development

Due to the combination of laser technology and computer technology, the laser print can be realized by the order from the computer program, and may change the print design at any time, replaces the traditional mold marking process from the fundamental, shorten the product upgrade cycle and provide a convenient tool for flexible production

| Product Details

|

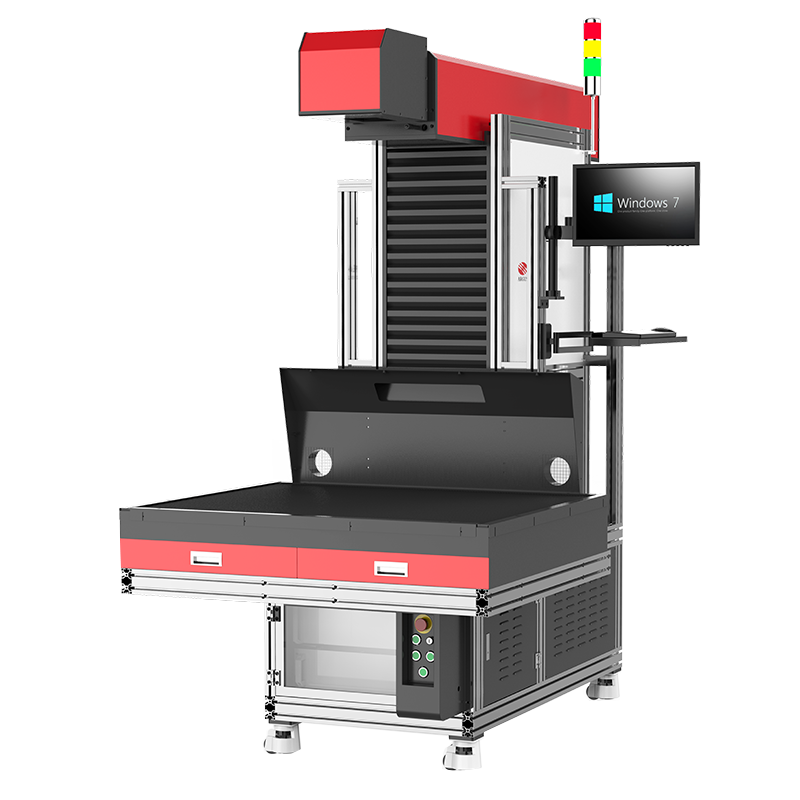

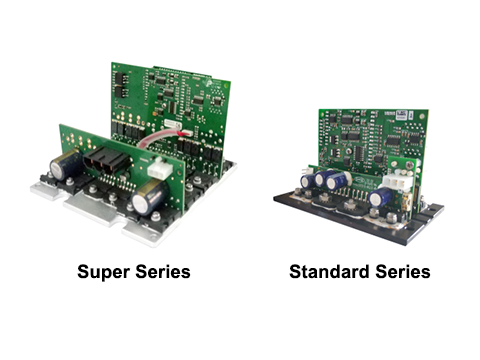

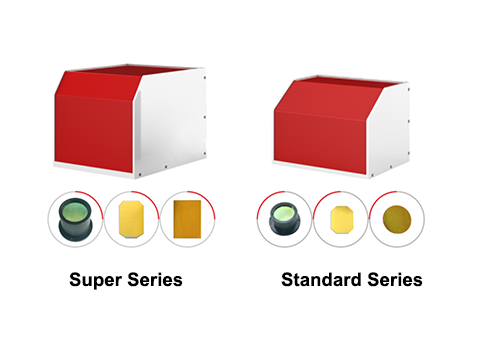

Galvo Scanning System Galvo head scan area could reach to 800*800mm once. 3D dynamic galvanometer control system ensure the best processing results . |

Original Imported Metal RF Laser Metal Tube high laser power,excellent laser spot, stable laser generation and life time of more than 20000hrs. |

|

|

CCD Optional

CCD positioning function ensures accurate and reliable position measurement greatly improves the production efficiency of the factory and saves labor. |

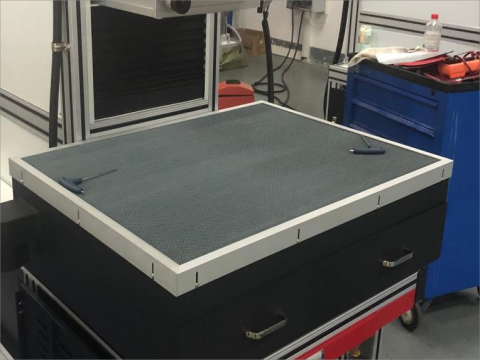

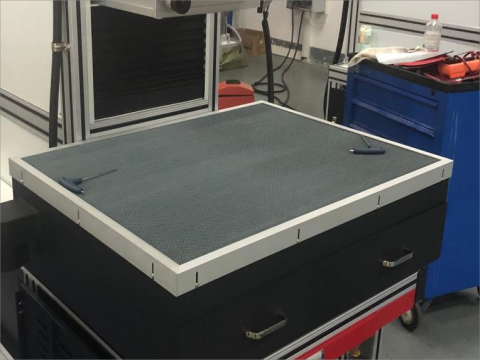

Worktable:Large marking Area Max marking area:800*800mm, can realize marking, cutting, craving process. |

|

Paper Sample Display

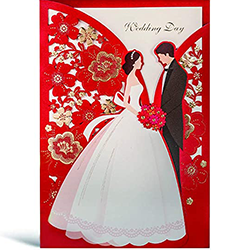

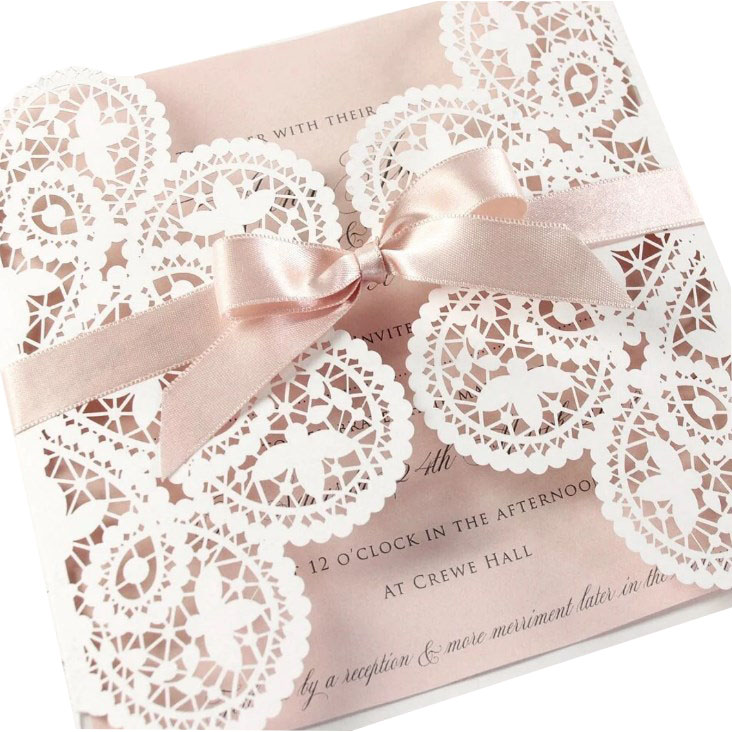

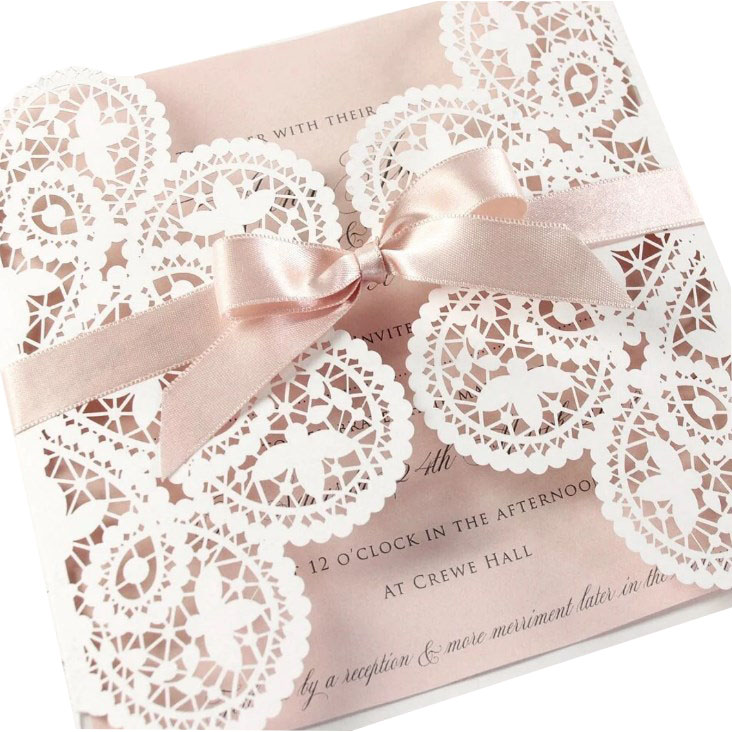

| >>Wedding Invitation Cards |

|

|  |  |

| >>Candy Boxes |

|

|  |  |

| >>3D Paper Caving Lamps |

|

|  |  |

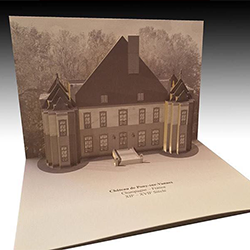

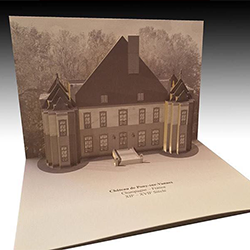

| >>Pop up Cards |

|

|

|  |

| >>Cupcake Rim |

|

|  |  |

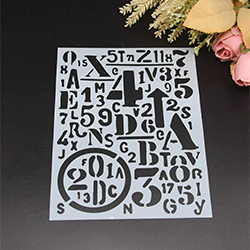

| >>Painting Template |

|

|  |  |

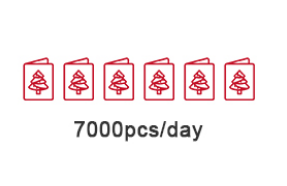

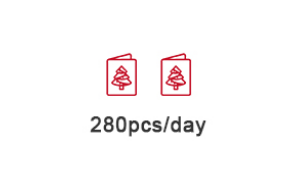

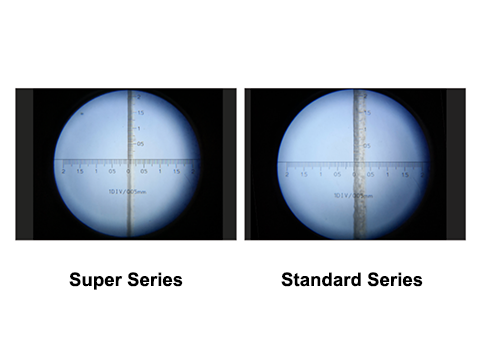

Comparison With Laser Engraving Machine

CO2 Dynamic laser marker | VS

|

CO2 laser engraver/cutter |

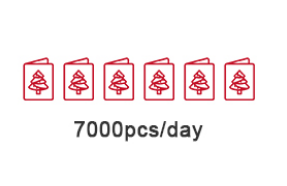

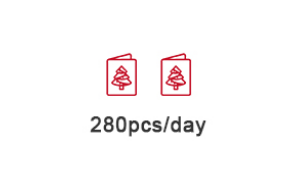

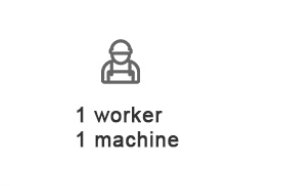

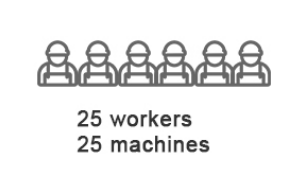

| Production Capacit |

|

| 7000pcs/day |

|

| Cutting Effect |

|