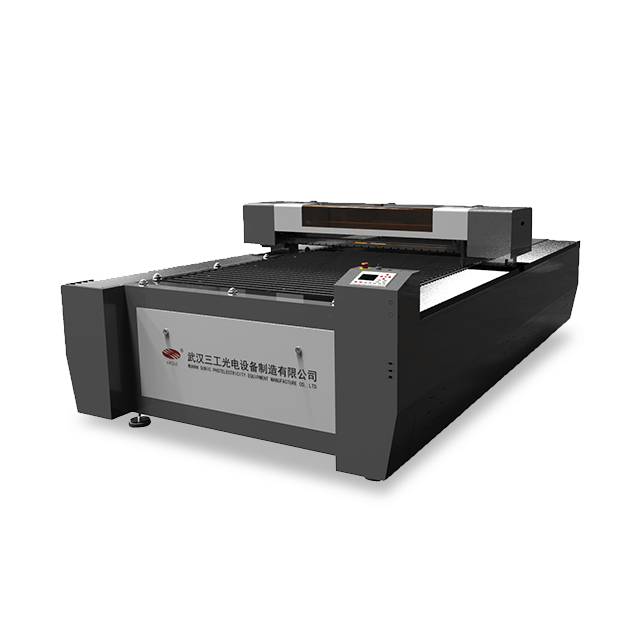

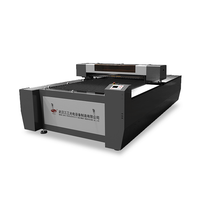

300W CO2 Laser MIX Cutting Machine for Metal Cutting

Equipment performance

1. Designed for cutting large size METAL and nonmetal materials. Configured with 300W Co2 Laser Tube. Sufficient stiffness machine body with 1300*2500mm worktable.

2.Aluminum alloy crossbeam & laser head, Import focus lens. Servomotor&Ball screws transmission, Laser cutting head height adjustable, RDCAM control system.

3. Module steel frame structure to reduce the mechanical trouble effectively.

4.Taiwan HIWIN liner guide rail, Routeway feeding.

5. Patent Design is applied in the machine, easy operation with the control panel of LCD screen worknormally.

6. The machine can cut the work piece smoothly and accurately by the big worktable.

7.Adopt imported USA laser optic lens. The lens of less energy loss, high reflectivity, strong focusing and durable. Optical less losses in the transmission process to avoid the problems of large attenuation of laser cutting power

1325 Laser Cutting Product Composition

Highest Quality,Precision Accuracy

| Machine Structure

Adopt Integral Casting Molding technology, improve the stiffness of the machine body, Ensure the stability of the crossbeam when high-speed working. The steel plate used in this machine adopts tempering and vibration aging to eliminate stress, support long lifespan.

|

Integrated Aluminum Crossbeam

New design crossbeam,heavier than the old type.Mainstructure made by integral casting molding,not welding by aluminum plates. lmprove the stability and motion inertia of crossbeam ensure the cutting accuracy |  |

| Adjustment of Guide Rail

We choose Taiwan HIWIN liner guide rail in order to ensure the precision of crossbeam motion. |

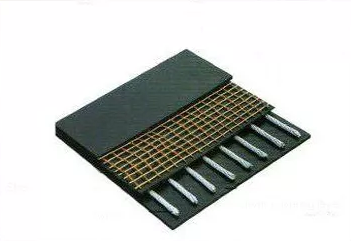

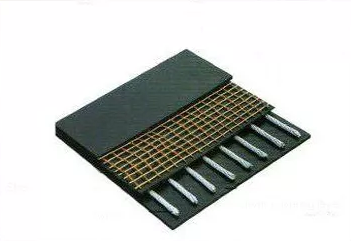

Steel Wire Belt

X,Y axis motion system adopts stepper motor-belt transmission, this new type SCU1325 use steel wire belt, contains internal steel wire.Compare with ordinary transmission belt, this kind of belt has higher stiffness, no deformation |  |

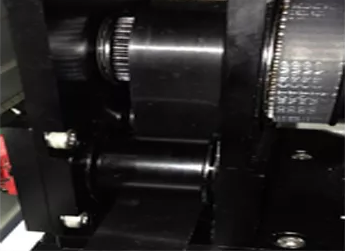

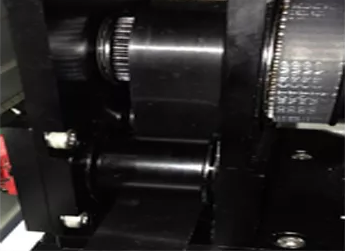

| New Design Ratio System

The ratio system which we designed for X axis motor adopts the“Ω”shaped transmission design, configured three additional driving wheel to ensure a high ratio to prevent the slipping of the belt Improve the accuracy of X-axis motion. |

1325 CO2 Laser Cutting Machine More Details

COMMON MATERIALS

TO PROCESS WITH CO2 LASER

| MATERIAL | CUT | ENGRAVE |

| Paper | ✔ | ✔ |

| Cloth | ✔ | ✔ |

| Wood | ✔ | ✔ |

| MDF | ✔ | ✔ |

| Wood Veneer | ✔ | ✔ |

| Acrylic | ✔ | ✔ |

| Leather | ✔ | ✔ |

| Matte Board | ✔ | ✔ |

| Cork | ✔ | ✔ |

| Rubber | ✔ | ✔ |

| Bamboo | ✔ | ✔ |

| Melamine | ✔ | ✔ |

| Plastic | ✔ | ✔ |

| Glass | X | ✔ |

| Ceramic | X | ✔ |

| Tile | X | ✔ |

| Marble | X | ✔ |

| Press Board | ✔ | ✔ |

| Home Textile | ✔ | ✔ |

| Anodized Aluminum | X

| ✔ |

| Tumbler | X | ✔ |

| Stone | X | ✔ |

| Appliques | ✔ | ✔ |

1325 CO2 Laser machine More possibilities