The current industrial regulations require parts to have clearly legible identifications, therefore, increasing the popularity of the laser marking process. Previous industrial trends required manufacturers to mark surfaces with traditional engraving or screen printing processes. These processes were non-permanent, costly, and usually caused part defects.

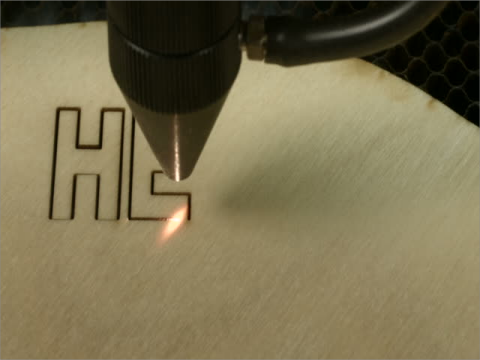

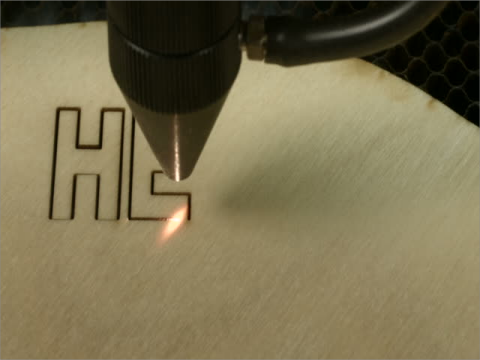

However, the introduction of laser marking now allows engineers and manufacturers to create numbers, images, or characters without compromising part quality. Instead of using physical tools for etching surfaces, this technique employs focused laser beams to create easy-to-read, damage-free marks.

Laser marking is a very versatile process, encompassing different techniques such as engraving, etching, foaming, carbon migration, etc. The right marking method will depend on your material and quality requirements. Read on as we discuss the details of this innovative technique.

What is Laser Marking and How Does it Work?

Laser marking is a process that uses a concentrated beam of light to create permanent marks on the surfaces of target components. The process is typically carried out with a laser machine using an oscillator, a scanning mirror, and a focusing lens.

The machine also allows automation and processing at high speeds, consequently leaving permanent traceable marks on a wide range of materials. Laser marking allows parts and products to be marked with:

Texts, including part numbers and serial numbers

Machine-readable data such as Unique ID codes, 2D Data Matrix codes, barcodes, etc.

Graphics

How Laser Marking Works

The laser marking technology creates lasting marks on component surfaces by generating focused beams of light containing high energy levels. The built-up energy is released in the coherent light beam directed at the material surface using mirrors.

As a result of the light beam interacting with the component’s surface, there is a transfer of heat energy from the beam to the surface. Therefore, the appearance and properties of the material will change. Depending on the energy level, the laser can engrave, etch, anneal, or discolor surfaces with great precision.

The concentrated beam targets only specific areas on the material, ensuring precise, high-contrast, and high-quality marks. These marks are permanent, and you can easily read or scan them on any surface. As a result, this marking process is ideal for operations where permanency and accuracy are critical.

Common Types of Laser Markers

There are many types of laser marking machines you can use for different applications. Each of these laser markers is ideal for different materials and operations.

CO2 Laser Markers

These laser markers are often sealed-tube marking systems with galvo-steered light beams designed to mark non-metal surfaces. CO2 laser markers are popular options for product recognition markings, logos, date stampings, and many more. These machines help create serial numbers, logos, and barcodes on electrical appliances, integrated circuits, food & medical packaging, and electronic components.

The wavelength of sealed-off CO2 lasers gives the best marking results with organic materials like papers, wood, and some plastic polymers. They are also suitable for leather and glass markings.

Pros & Cons

This laser marking machine is suitable for coated metals like painted brass and coated aluminum. There is no need for any pre-treatment with CO2 laser marking. The fact that you can use it for various non-metals makes it a versatile process for many industries, from electronic to medical and packaging industries.

However, getting a CO2 laser machine that supplies big power can be quite expensive. Furthermore, energy consumption and operation requirements with this type of laser marker are high, increasing overall costs incurred.

Fiber Laser Makers

The popularity of this laser marking technology has grown in recent times because these laser markers are among the most powerful available today. These solid-state lasers have power levels ranging from 20 to 50 watts, stimulating the production of ytterbium, a rare-earth metal. This metal element generates photons of about 1,090 nm wavelength, which is ideal for marking metal materials.

The fiber laser marking machine is suitable for depth engraving or etching. They offer greater results on harder metals or when you need a high-powered system with smaller spot sizes to get higher resolution. As a result of the small spot sizes, high beam quality, and larger lenses, these markers are ideal for small-component batch markings.

Pros & Cons

The fiber laser setup is highly versatile and creates marks more effectively at faster marking speeds. This laser marking technology also boasts zero consumable requirements, economic power usage, and minimal maintenance, making it more affordable than CO2 lasers.

The high level of monochromatic beam filtration ensures you get varying powers of one type of beam. Therefore, you can use fiber lasers on many kinds of surfaces. Varying the wattage on these laser markers allows you to archive various engraving depths based on your component’s applications.

However, it may not work fast on very thick materials with high reflection properties. It may also not be able to create deeper engravings on most metals.

Other Laser Markers

Besides the common laser markers discussed above, there are other laser marking machines that deliver great results. They include:

● Green Laser Markers

Green lasers operate in the green visible light spectrum (532 nm) with power ranging from 5 to 10 watts. They are designed to create marks on highly reflective materials. In addition, they exhibit high precision and excellent work ease, making them ideal for sensitive substrates such as silicon wafers. These lasers display greater absorption for different materials and mitigated thermal energy. Therefore, they are excellent for soft plastics, circuit chips, PCB boards, etc.

● UV Laser Markers

UV lasers are designed with a highly absorptive wavelength of 355 nm for part marking. As a result of their high absorption rate, they are perfect for “cold marking,” ensuring there are no heat stresses on the material. UV lasers can mark several surfaces such as plastics, glass, and ceramics. The high-quality beam can also micro-mark electronic materials and medical equipment with precise marking.

Advantages of Laser Marking

The advances in marketing techniques have opened the eyes of project managers to the need to brand their products. As a result, laser marking is now an essential part of manufacturing processes, helping businesses track their products, minimize counterfeiting, improve quality, and more. It helps you make precise markings with high precision, saving you time and money.

To help you understand the great potential of this marking technology, here are some benefits to keep in mind:

High Production Speed

Laser marking combines laser technology with computer technology, ensuring faster implementation and time-saving. This technique allows you to create designs on a computer and use the latest graphic design technology.

Conventional marking methods use specific tools that make the processing time-consuming. On the other hand, laser marking machines only need a command to get the job done within a short period. This is the perfect option for shortening a product’s development cycle, speeding up your processes, and saving you lots of money.

Eco-friendly Production Process

Marking processes like chemical etching and inkjet use chemicals and inks for marking. These consumables are often expensive and release harmful fumes to the environment, which can have negative effects. However, laser marking does not make use of any consumables. Therefore, it is a clean, energy-efficient, and environmentally friendly process.

Likewise, this marking technique is a non-contact process, ensuring clean processing and limiting material contamination. While other printing systems may burn the material down, laser marking is damage-free, involving little to no material penetration.

Compatible with Most Materials

There are various laser marking machines, and each marker can work on a wide variety of materials. For instance, CO2 lasers give the best marking results with organic materials like papers, wood, and some plastic polymers.

Likewise, fiber lasers can work with various metal grades, including steel, aluminum alloys, stainless steel, etc. UV lasers can mark surfaces such as plastics, glass, and ceramics.

Consistent Repeatability

Laser markers can successfully mark a larger product batch with a specific design within a mass manufacturing setup. This marking technique makes it easy to integrate identical markings into a production line. Furthermore, the repeatability is consistent, allowing faster turnaround times and aesthetically-pleasing products.

Durability of Marks

Marks created by lasers are usually permanent with high contrast properties. These water-resistant and fade-proof marks can withstand abrasion, heat, and acids. Therefore, laser markings are the best choices for durable marking needed for reliable product tracing, and you won’t have to fear the mark fading off.

Low Maintenance Process

Laser marking is a no-contact technique. Thus, there is no mechanical wear between the laser marking system and the workpiece. This ensures that maintenance and downtime are kept to a minimum. You also need low maintenance to remove any accumulated dust from the mirrors used.

Applications of Laser Marking

The possible use-cases of laser markings continue to increase, thanks to the ever-developing technology. Therefore, laser marking processes now find applications in an extensive range of industries.

Many industrial and commercial products require labeling. These products include machine tools, integrated circuits, keyboard buttons, food packings, medical equipment, printed circuit boards, and many more. Laser marking helps create these labels, including model and serial numbers, QR codes, bar codes, part numbers, logos, dates, etc.

Traceable information is often required for quality control. Laser marking also helps to create permanent identification markers on various components. Examples include silicon wafers for photovoltaic cells, indications on electronics, smart cards on automotive parts, and more. This way, you can easily trace back and solve possible problems quickly.