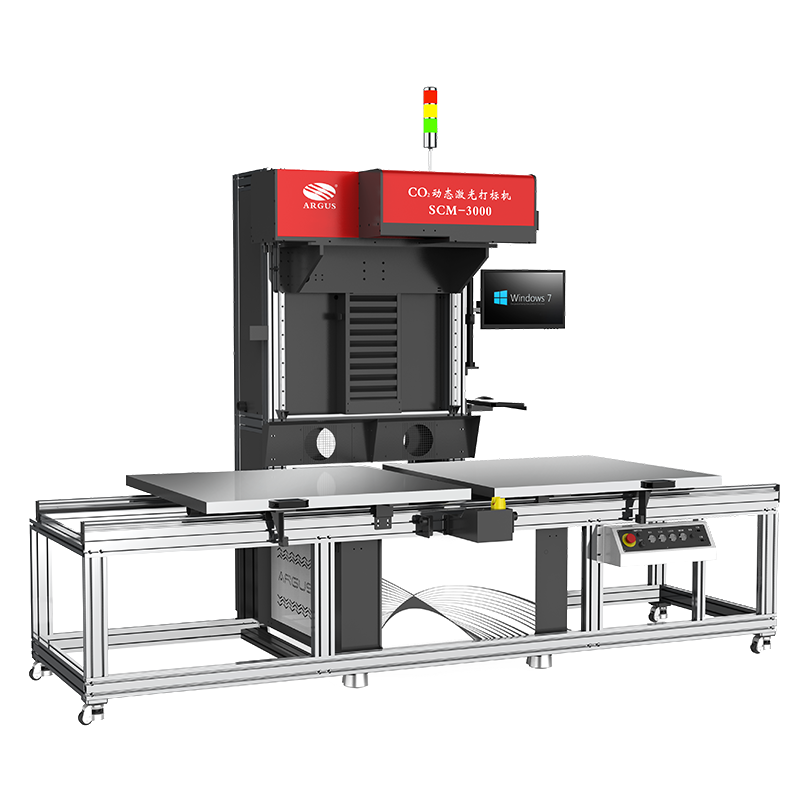

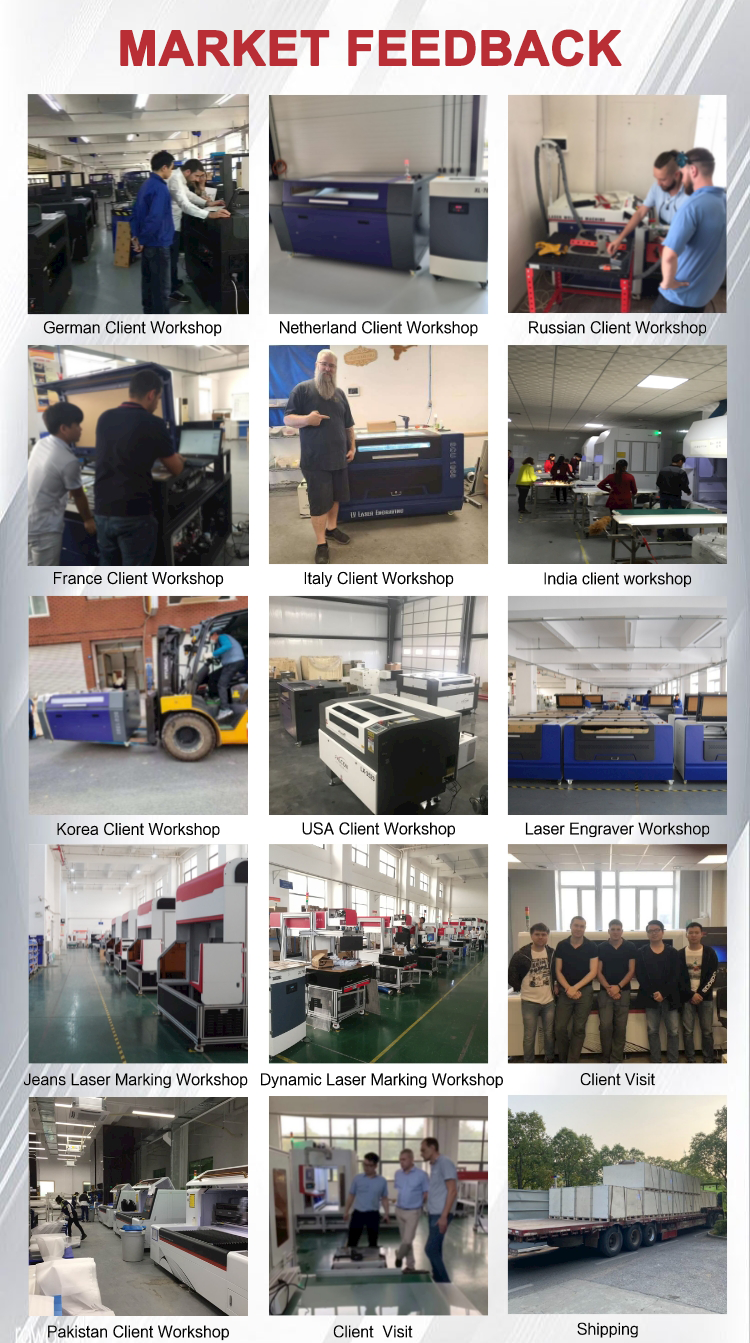

| Product Description

Main Features

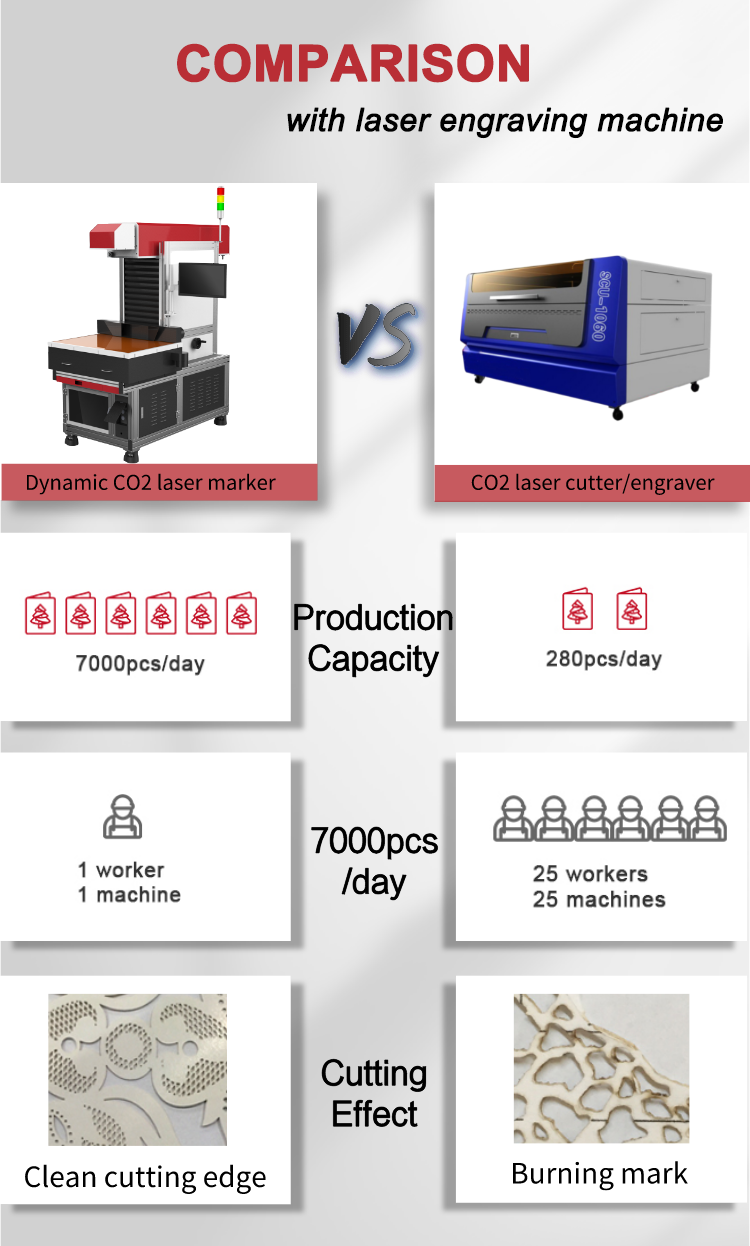

1.High marking speed: maximum 7000mm/s marking speed with high-speed galvanometer scanning. Suitable for industrial mass production.

2.Large marking area: Max marking area 600*600mm ,can realize marking, punching, cutting, carving process.

3.Good stability of the equipment: Adopted the full closed optical path, imported of CO2 R.F laser source, strict multiple protection control design, ensure the stability of the entire equipment.

4.Red light indicator, makes you find out the working area easily.

| Product Details

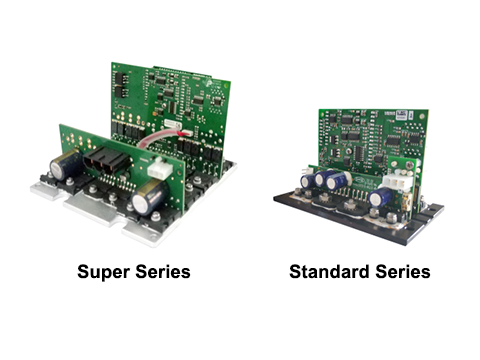

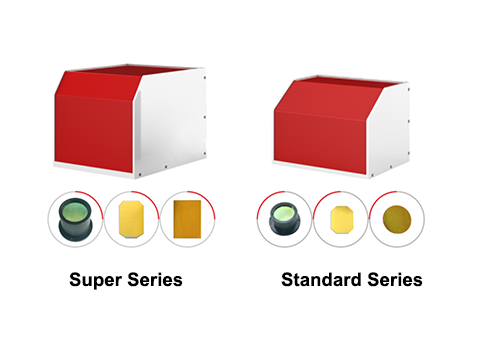

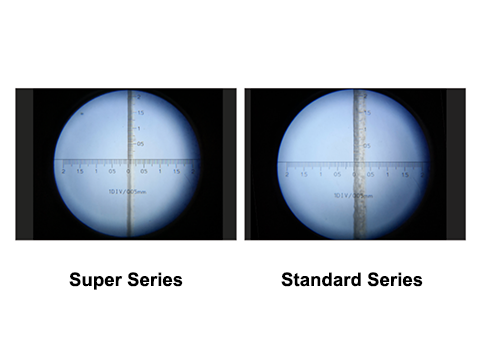

Galvo Scanning System

3D dynamic Galvo head,one time scan area could reach to 800*800mm.

3D dynamic galvanometer control system ensure the best processing results .

RF Laser Metal Tube

Original imported metal RF laser tube with high laser power,excellent laser spot, stable laser generation and life time of more than 20000hrs.

CCD Optional

CCD positioning function ensures accurate and reliable position measurement greatly improves the production efficiency of the factory and saves labor.

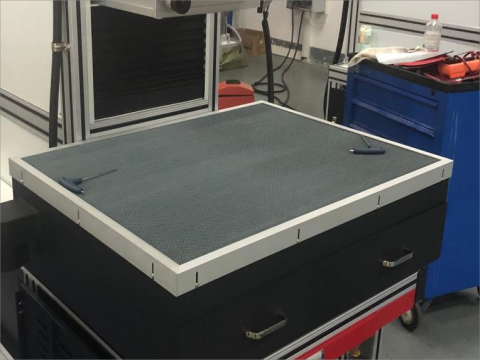

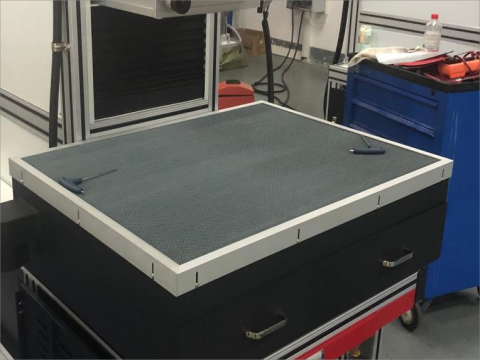

Worktable

Large marking area :Max marking area 800*800mm, can realize marking,

cutting, craving process.