1) Simple structure in linear type, easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automation and intellectualize, no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine

Product Application

visuvisual positional automatic vamp marking machineal positional automatic vamp marking machine

This machine is used for drawing/ inking sewing mark for shoes. It is visual positional,can catch the material even placed in random. Placing, working and collecting in one conveyor belt, can save a lot of work.

1.Easy to operate, you can draw the design by mouse in the machine,or creat your design by CAD/CORELDRAW,transfer into DXF then upload into the machine .

2.different size or design can be reganized and marked in the same time,

3.High speed, placing , working and collecting in the same time, 10 times than to manual.

If add auto feeding machine and conveyor, one person can operate several machines.

4.The material fixed by vacuum, to guarantee the accuracy.

5.Visual position, no need to make dies.

6.Can use many kinds of ink.

Technical Parameters

Working Area | 1800mm*1400mm | Software | Argus |

Laser Type | CO2 Glass Laser Tube | Working Speed | 200-600 mm/s |

Laser Power | 120W | Power Supply Requirements | AC110V~220V±5% 50Hz/60Hz 1Phase |

Heads of Laser | Single/Double | Format Supported | AI\BMP\PLT\DXF\DST |

Dimensions with Wood Package | 2.5*2.09*1.32M 2.5*1.5*0.9M | Positioning Accuracy | ±0.1mm |

Gross Weight | 1050KGS | Operating Temperature | minus 10℃~45℃ |

Motion System | Step Motor | Operating Humidity | 5-95% |

Cooling System | Industrial Water Chiller | Total Power | <1.5KW (Excluding exhauster) |

| Vision Laser Cutting Machine Main Technical Parameters |

| Laser Type | Co2 glass laser tube |

| Laser Power | 80W / 100W /120W |

| Working Area | 1,800mmX1,200mm & 1,800mmX1,600mm |

| Working Table | Conveyor working table |

| Working Speed | 0-6400 mm/min |

| Positioning Accuracy | ±10% |

| Cooling System | Constant temperature water chiller |

| Format Supported | AI\BMP\PLT\DXF\DWD\JPEG\PCX\CDR |

| Standard Collocation | 1,100WX2 sets of bottom exhaust fans, 1 camera |

| Optional Collocation | Automatic feeding system, 200W Co2 RF laser tube |

| Power Supply Requirements | AC220V±5% 50Hz |

| Gross Power | <1800W |

| Dimension | 2600x2450x2500mm |

| Weight | 480Kg |

Working Processing

Dye sublimation printing onto large format textiles is now very popular for producing Sportswear, Flags & Banners, due to the printers becoming faster and more cost effective. The only issue remaining is how cut out the printed parts. Traditional cutting is too slow, inconsistent and labour intensive.

New Large vision laser cutting machine , automates the process of cutting out dye sublimation printed pieces of fabric or textile both quickly and accurately, automatically compensating for any distortions or stretches that occur in unstable or stretchy textiles - exactly the type of fabrics that are used in sportswear

Wuhan Sunic Photoelectricity Equipment Manufacture Co.,Ltd (Sunic Laser) have been engaged in manufacture of laser equipments since 1998. We are specialized in designing, manufacture, sales and service for laser processing machines and whole equipment for

Solar PV production line, and supply complete turnkey solutions with laser application for customers all over the world.Our laser equipment are widely used in Solar PV production, IC elements production, Leather&Clothing industry, Advertising Signs,Decoration crafts, equipment spare parts, daily hardware, measurement tools, medical instruments, printing & packing industry and etc. Sunic Laser would like to be customer’s technical consultant and support in laser&solar equipment to make further development and progress together.

Smaples

FAQ

Q1: I knew nothing about machine, How can I get the best one for me?

Pls you tell us your working material, detail work by picture or video so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.

Q2: This is the first time I use this kind of machine, is it easy to operate?

We'll send you manual and guide video in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can talk by phone, email or other contact ways.

Q3: If the machine has problem in my place, how could I do?

We could send free parts to you in warranty period if machines have any problem under "normal use".

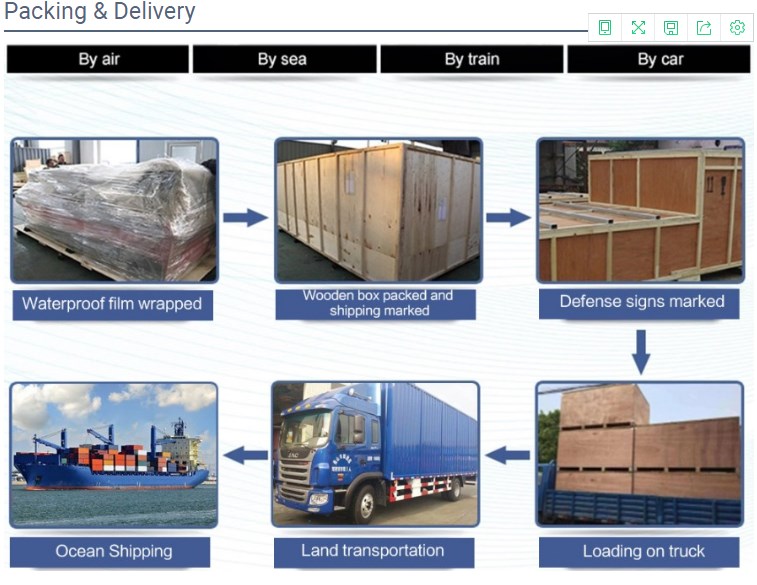

Q4: How long is the delivery time?

For standard machines, it would be 7-10 workdays; For non-standard machines and customized machines according to your specific requirements, it would be 20 to 30 workdays.